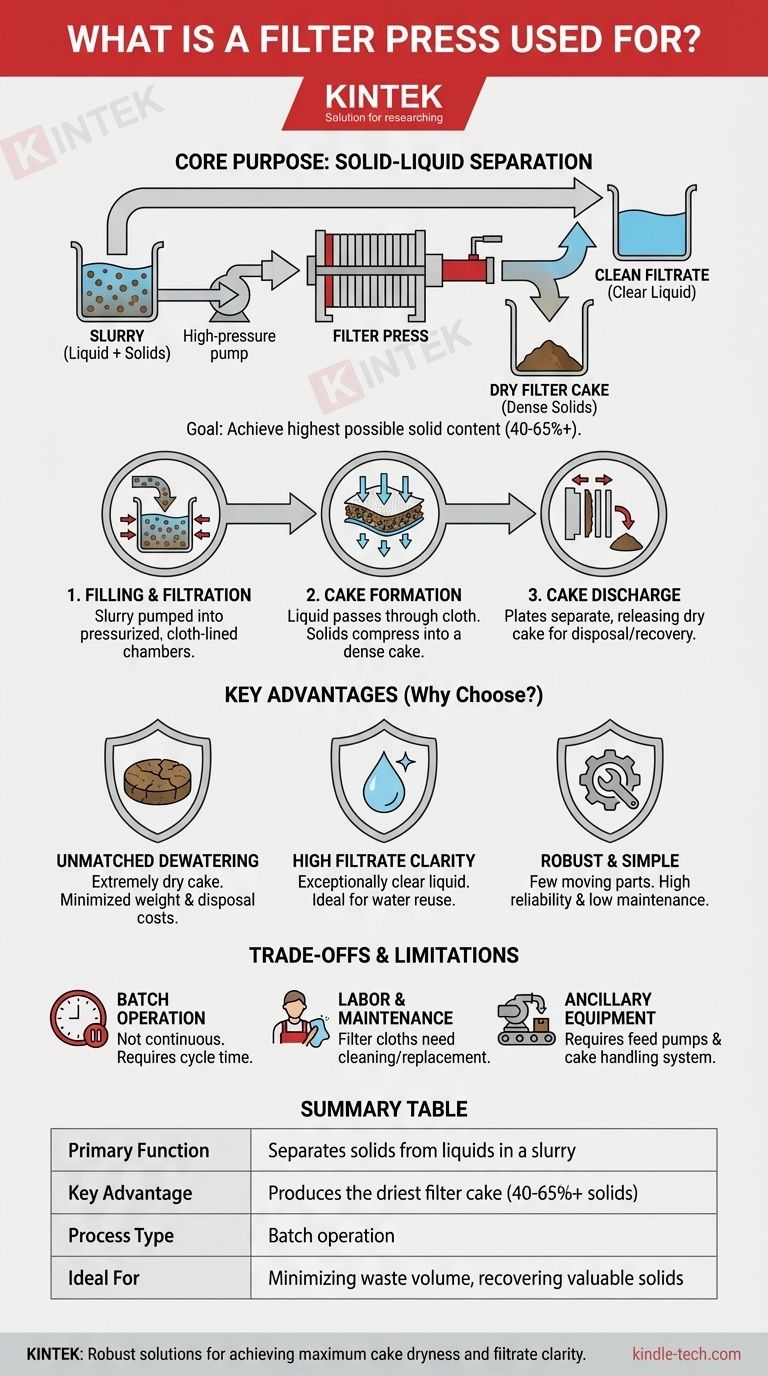

At its core, a filter press is a highly efficient machine designed for one primary purpose: separating solids from liquids in a slurry. It accomplishes this by pumping a liquid-solid mixture into a series of chambers and applying immense pressure, forcing the liquid through a filter medium while trapping the solids. The result is a stream of clean liquid (filtrate) and a dense, dry solid material known as a "filter cake."

The central reason to use a filter press over other separation technologies is its ability to produce the highest possible solid content in the resulting filter cake. This unmatched dewatering capability is critical for industries looking to minimize waste volume, reduce disposal costs, or recover valuable solid products.

The Fundamental Operating Principle

A filter press operates as a batch process, meaning it completes its cycle one batch at a time. While designs vary, the core principle is consistent and can be understood as a three-stage cycle.

Stage 1: Filling and Filtration

A high-pressure pump feeds the slurry into the press. The press itself consists of a series of plates held together under extreme hydraulic pressure, creating a set of sealed chambers. Each plate is lined with a filter cloth, which acts as the separation medium.

Stage 2: Cake Formation

As the slurry fills the chambers, the pressure from the pump forces the liquid component to pass through the filter cloths, leaving the solid particles behind. The liquid, now called filtrate, exits through ports in the plates and is collected. The trapped solids accumulate and compress, forming a dense, dry cake between the plates.

Stage 3: Cake Discharge

Once the chambers are full of solids and the filtrate flow diminishes, the pump is stopped. The hydraulic pressure holding the plates together is released, and the plates are separated. This allows the solid filter cakes to fall out of the press, ready for disposal or further processing.

Why Choose a Filter Press? The Key Advantages

Engineers and operators specify a filter press when the final state of the solids is the most important factor. Its primary benefits stem directly from its high-pressure, static filtration method.

Unmatched Dewatering Performance

The key advantage is the production of extremely dry filter cakes, often achieving 40-65% solids content or higher, depending on the material. This is significantly drier than what can typically be achieved with centrifuges or belt presses. Drier cake means lower weight and volume, drastically reducing transportation and disposal costs.

High Filtrate Clarity

Because the filter cake itself acts as a depth filter, the liquid filtrate produced is exceptionally clear. This is crucial for applications where the water is being reclaimed for reuse within the plant or must meet strict environmental discharge regulations.

Robustness and Simplicity

Filter presses are mechanically straightforward with few moving parts compared to other dewatering equipment. This translates to high reliability, lower maintenance costs, and a long operational lifespan, making them a workhorse in harsh industrial environments like mining and wastewater treatment.

Understanding the Trade-offs and Limitations

No technology is perfect for every scenario. The primary trade-offs of a filter press are linked to its operational mode and setup.

Batch Operation vs. Continuous Flow

The most significant characteristic is its batch process. This can be a limitation for production lines that require a continuous, uninterrupted flow. The cycle time can range from 30 minutes to several hours, which must be factored into the overall process design.

Labor and Maintenance

While modern presses are highly automated, they still require operator oversight. The filter cloths are a critical component and a primary consumable. They must be periodically cleaned or replaced to prevent "blinding," where the pores become clogged, reducing efficiency.

Ancillary Equipment Requirements

A filter press system doesn't operate in isolation. It requires a powerful, high-pressure feed pump specifically designed for abrasive slurries. It also needs a system to handle the discharged cake, such as a conveyor or hopper, which adds to the overall system footprint and cost.

Making the Right Choice for Your Goal

Selecting the right dewatering technology depends entirely on your primary objective. A filter press is the ideal solution for specific, demanding applications.

- If your primary focus is maximum cake dryness: A filter press is almost always the superior choice, especially for minimizing waste disposal costs or maximizing the recovery of a solid product.

- If your primary focus is high-volume, continuous processing: You may need to evaluate technologies like a belt press or centrifuge, accepting that you will get a wetter solid output.

- If your primary focus is high filtrate quality for water reuse: A filter press provides excellent performance, ensuring the cleanest possible water return to your process.

Ultimately, a filter press is the definitive choice when the quality and dryness of the final solid cake are the most critical drivers of your operational success.

Summary Table:

| Aspect | Key Characteristic |

|---|---|

| Primary Function | Separates solids from liquids in a slurry |

| Key Advantage | Produces the driest filter cake (40-65%+ solids) |

| Process Type | Batch operation |

| Ideal For | Minimizing waste volume, reducing disposal costs, recovering valuable solids |

| Main Limitation | Not a continuous process; requires cycle time between batches |

Need to dewater your slurry efficiently and reduce disposal costs? KINTEK specializes in robust laboratory equipment and consumables, including filtration solutions for demanding industrial and research applications. Our expertise can help you select the right system to achieve maximum cake dryness and filtrate clarity for your specific needs. Contact our experts today to discuss your separation challenges and optimize your process!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components