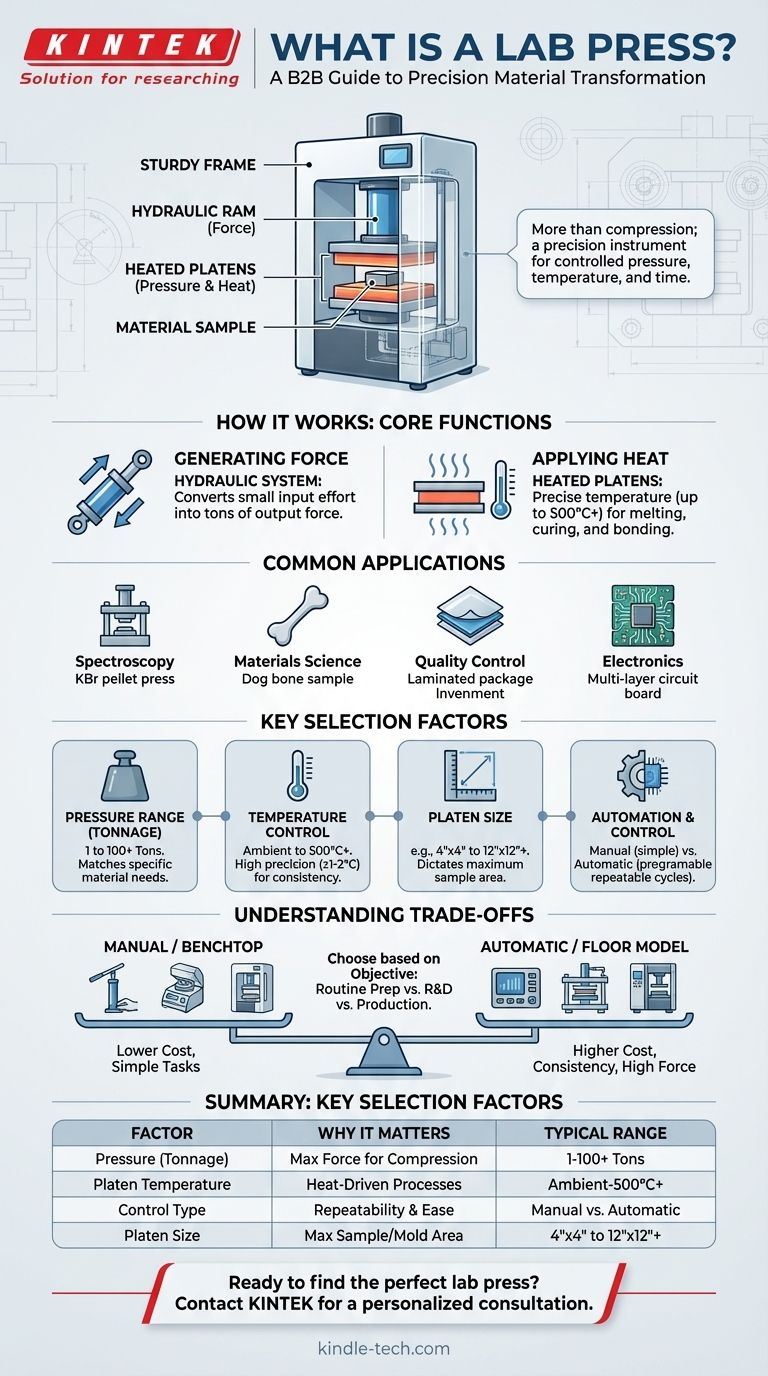

In essence, a laboratory press is a compact machine designed to apply a precise amount of force, often combined with heat, to a material sample. It is a fundamental tool used across scientific research and quality control for compressing, molding, laminating, and preparing materials in a highly controlled and repeatable manner. The core components consist of a sturdy frame, a force-generating system (typically hydraulic), and two parallel plates, known as platens, that exert the pressure.

A laboratory press is more than a simple compression device; it is a precision instrument for material transformation. The key to its effective use is not just its maximum force, but the deliberate control of pressure, temperature, and time to achieve a specific, desired outcome in a material.

The Core Functions: Applying Controlled Force and Heat

A lab press operates on a straightforward principle: converting a small input effort into a large output force, often with the addition of thermal energy. Understanding how it achieves this is key to understanding its value.

How a Lab Press Generates Force

The vast majority of lab presses use a hydraulic system to generate force. This can be a simple manual hand pump, similar to a car jack, or an automated, electrically powered pump.

This hydraulic action pushes a ram, which in turn moves one of the platens toward the other fixed platen. The resulting force, measured in tons, is what compresses the sample placed between them.

The Role of Heated Platens

Many applications require heat to facilitate a material change. Lab presses can be equipped with electrically heated platens that can reach specific, stable temperatures.

This allows for processes like melting polymers for molding, curing thermoset resins, bonding layers of materials together (lamination), or simply studying a material's behavior under thermal stress.

Common Applications

Lab presses are versatile tools used in many fields:

- Materials Science: Molding polymer plaques or "dog bones" for tensile testing.

- Spectroscopy: Creating KBr pellets for FTIR analysis.

- Quality Control: Testing the lamination strength of packaging materials.

- Electronics: Prototyping multi-layer circuit boards.

- Geology: Simulating high-pressure conditions on rock samples.

Key Parameters for Selecting a Lab Press

Choosing a lab press requires a clear understanding of your specific application. The right machine is the one whose capabilities match your experimental needs.

Pressure Range (Tonnage)

The maximum force a press can generate is its most defining characteristic, often expressed in tonnage. A small, 12-ton press may be perfect for preparing small pellets, while a 50-ton press might be required for molding dense, high-performance composites. Over-specifying tonnage adds unnecessary cost and footprint.

Temperature Control and Range

If your process requires heat, three factors are critical:

- Maximum Temperature: Ensure the press can reach and exceed the processing temperature of your material.

- Temperature Precision: How accurately does the press hold a set temperature? Research applications often demand control within ±1-2°C.

- Dwell Time: This is the duration the press holds both pressure and temperature. Simple applications may need a few seconds, while complex curing cycles can last for hours.

Platen Size

The size of the platens dictates the maximum surface area of your sample. Platen size should be chosen based on the dimensions of the molds you intend to use or the samples you need to produce. A larger platen is not always better, as it requires more energy to heat and a more robust frame.

Automation and Control

The level of control separates basic presses from advanced ones.

- Manual presses require an operator to pump the handle to build pressure and manually monitor gauges. They are simple and cost-effective.

- Automatic presses feature programmable controllers. An operator can set the desired pressure, temperature, and time, and the press will execute the multi-step cycle automatically. This ensures unmatched repeatability and is crucial for complex processes or research where consistency is paramount.

Understanding the Trade-offs

There is no single "best" lab press; there is only the best press for a specific task and budget. Making an informed choice means acknowledging the inherent trade-offs.

Manual vs. Automatic Presses

The primary trade-off here is between cost and consistency. A manual press is an excellent, affordable choice for simple, non-critical tasks. An automatic press is a significant investment, but it is essential for applications where process parameters must be precisely replicated every single time.

Benchtop vs. Floor Models

This is a decision based on force requirements and available space. Benchtop models are compact and ideal for forces typically up to 30 tons. Higher-tonnage presses (50-100+ tons) require larger, heavier frames and hydraulic systems, necessitating a floor-standing design for stability and safety.

The Cost of Precision

Higher precision comes at a higher price. Features like water-cooling channels for rapid cool-downs, vacuum-enclosed chambers for atmosphere control, and highly accurate temperature/pressure sensors all add to the complexity and cost of the machine. It is critical to justify these features against the demands of your application.

Making the Right Choice for Your Goal

To select the correct instrument, start by defining your primary objective. This will immediately clarify which features are essential and which are optional.

- If your primary focus is routine sample preparation (e.g., KBr pellets): A simple, manual benchtop press with low tonnage (1-15 tons) and no heat is often sufficient and highly cost-effective.

- If your primary focus is materials R&D (e.g., polymer formulation): Prioritize an automatic press with precise temperature control, programmable cycles, and a pressure range suitable for your materials.

- If your primary focus is small-scale production or large samples (e.g., lamination): A larger, automated floor press will likely be necessary to accommodate sample size and ensure consistent throughput.

By first defining your material processing goals, you can select a lab press that serves as a powerful and precise tool for your work.

Summary Table:

| Key Selection Factor | Why It Matters | Typical Range |

|---|---|---|

| Pressure (Tonnage) | Determines the maximum force for compression | 1 to 100+ tons |

| Platen Temperature | Enables heat-driven processes like curing & molding | Ambient to 500°C+ |

| Control Type | Impacts repeatability and ease of use | Manual vs. Automatic |

| Platen Size | Dictates the maximum sample or mold area | 4"x4" to 12"x12"+ |

Ready to find the perfect lab press for your application?

KINTEK specializes in high-quality lab equipment, including a full range of manual and automatic laboratory presses designed for precision, durability, and repeatability. Whether your focus is routine sample preparation, advanced materials R&D, or small-scale production, our experts can help you select the ideal press to meet your specific pressure, temperature, and control requirements.

Contact our team today for a personalized consultation and discover how the right lab press can enhance your research and quality control processes.

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is considered high pressure for hydraulics? A Guide to Modern System Ranges

- What size sample is needed for XRF? Optimize Your Analysis with the Right Preparation

- What is the use of KBr in FTIR? A Key Technique for Accurate Solid Sample Analysis

- What is machine pressed laminate? The Standard Manufacturing Process Explained

- Why must a hydraulic press apply 720 MPa for solid-state batteries? Achieve Optimal Ion Path & Density

- Which is better EDX or XRF? Choose the Right Elemental Analysis Tool for Your Needs

- How does a hydraulic press facilitate the assembly of anode-free solid-state batteries? Achieve 520 MPa Precision

- How does a laboratory hydraulic press ensure the quality of oxide ceramic bulk materials? Achieve Precision Compaction