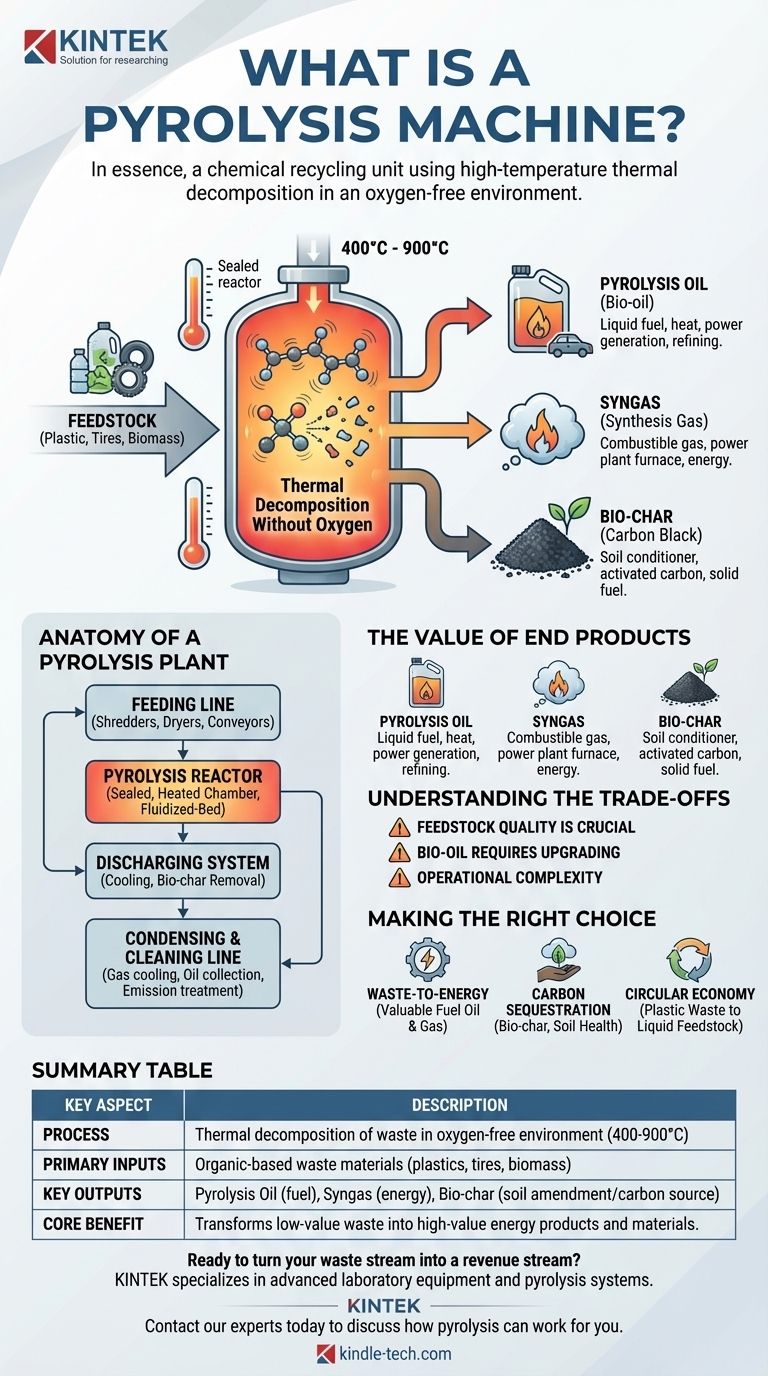

In essence, a pyrolysis machine is a chemical recycling unit. It uses a process called pyrolysis—high-temperature thermal decomposition in an oxygen-free environment—to break down organic-based waste materials like plastics, tires, or biomass. Instead of burning the material, which would produce ash and pollutants, the machine deconstructs its molecular structure to create valuable new products: a liquid fuel (pyrolysis oil), a combustible gas (syngas), and a solid, carbon-rich residue (bio-char).

A pyrolysis machine is best understood not as an incinerator, but as a refinery. It transforms low-value waste into high-value energy products and materials by breaking down complex molecules with intense heat, all without combustion.

The Core Principle: Thermal Decomposition Without Oxygen

Pyrolysis technology hinges on one critical factor: the absence of oxygen. By preventing combustion, the process forces a different chemical reaction that preserves the energy and carbon locked within the waste material.

How It Works

A pyrolysis machine, or plant, feeds waste material into a sealed reactor. This reactor is heated to very high temperatures, typically between 400°C and 900°C.

The intense heat and pressure cause the long-chain polymer molecules in the waste to vibrate and break apart into smaller, simpler components. This process is similar to the thermal cracking used in traditional oil refining.

The Key Outputs

The process consistently yields three primary products, each with its own use.

- Pyrolysis Oil (Bio-oil): A liquid fuel composed of a complex mixture of oxygenated organic compounds, polymers, and water. It can be used for heat, power generation, or further refined.

- Syngas (Synthesis Gas): A mix of non-condensable gases (like hydrogen, methane, and carbon monoxide) that is combustible.

- Bio-char (or Carbon Black): The solid, carbon-rich residue left after the process is complete.

Anatomy of a Pyrolysis Plant

A complete pyrolysis system is more than just a reactor. It is an integrated plant with several key stages designed for continuous and efficient operation.

The Feeding Line

This is the system that prepares and feeds the raw material into the reactor. Depending on the feedstock (e.g., shredded tires vs. wood chips), this may involve shredders, dryers, and conveyor systems.

The Pyrolysis Reactor

This is the heart of the machine. It's the sealed, oxygen-free chamber where the material is heated. A common advanced design is the fluidized-bed reactor.

In this design, the reactor contains a bed of inert material like sand. A gas (usually nitrogen) is pumped from below, causing the sand and feedstock particles to act like a fluid. This ensures extremely efficient and uniform heat transfer, maximizing the yield of valuable liquids and gases.

The Discharging System

This component is responsible for safely cooling and removing the solid bio-char from the reactor once the cycle is complete.

The Condensing & Cleaning Line

As the hot gases exit the reactor, they enter a series of condensers. These cool the gas, causing the pyrolysis oil to condense into a liquid for collection. The remaining syngas is cleaned and piped away, while any emissions are treated to meet environmental standards.

The Value of the End Products

The versatility of the outputs is what makes pyrolysis a compelling technology for waste management and resource recovery.

Bio-Oil: A Versatile Liquid Fuel

Pyrolysis oil can be combusted directly in industrial furnaces or boilers to generate heat and electricity. It can also serve as a feedstock for further refining into higher-grade transportation fuels or valuable specialty chemicals.

Bio-Char: More Than Just Charcoal

Bio-char is a stable form of carbon that has numerous applications. It can be used as a powerful soil conditioner to improve agricultural yields, as a base material for producing activated carbon, or as a solid fuel.

Syngas: Powering the Process

A significant portion of the syngas produced is often redirected back to the plant's furnace. This provides the heat needed to run the pyrolysis reactor, dramatically reducing the system's reliance on external energy sources and improving its overall efficiency.

Understanding the Trade-offs

While powerful, pyrolysis technology is not a magic bullet. Its effectiveness is subject to several practical considerations.

Feedstock Quality Is Crucial

The composition of the input material directly impacts the quality and yield of the final products. Contaminants, moisture content, and the chemical makeup of the waste must be carefully managed for consistent results.

Bio-Oil Requires Upgrading

Pyrolysis oil is not a direct, drop-in replacement for diesel or gasoline. Due to its oxygen content and chemical complexity, it is often corrosive and unstable, requiring further processing or upgrading before it can be used in standard engines.

Operational Complexity

Running a pyrolysis plant is a sophisticated industrial process. It requires precise control systems to manage temperature, pressure, and material flow safely and efficiently. This is not a simple "set it and forget it" technology.

Making the Right Choice for Your Goal

Pyrolysis can be applied to solve several different problems, and the best approach depends on your specific objective.

- If your primary focus is waste-to-energy: Pyrolysis is highly effective for converting non-recyclable plastics and end-of-life tires into a valuable fuel oil and a combustible gas.

- If your primary focus is carbon sequestration and soil health: Pyrolysis of biomass (like agricultural waste) produces bio-char, an exceptional soil amendment that improves fertility and locks carbon in the ground for centuries.

- If your primary focus is creating a circular economy: The process can transform plastic waste back into a liquid feedstock, which can be refined to produce new plastics and chemicals.

Ultimately, a pyrolysis machine is a powerful tool of chemical transformation, capable of turning problematic waste streams back into valuable resources.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Thermal decomposition of waste in an oxygen-free environment (400-900°C). |

| Primary Inputs | Organic-based waste materials (plastics, tires, biomass). |

| Key Outputs | Pyrolysis Oil (fuel), Syngas (energy), Bio-char (soil amendment/carbon source). |

| Core Benefit | Transforms low-value waste into high-value energy products and materials. |

Ready to turn your waste stream into a revenue stream?

A pyrolysis machine is a sophisticated chemical recycling solution, and choosing the right system is critical for your project's success. KINTEK specializes in advanced laboratory equipment and pyrolysis systems for R&D and pilot-scale operations, helping you test and optimize the process for your specific feedstock and goals.

Contact our experts today to discuss how pyrolysis can work for you. We'll help you understand the technology, its applications for your materials, and the path to a more sustainable and profitable operation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Small Lab Rubber Calendering Machine

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs