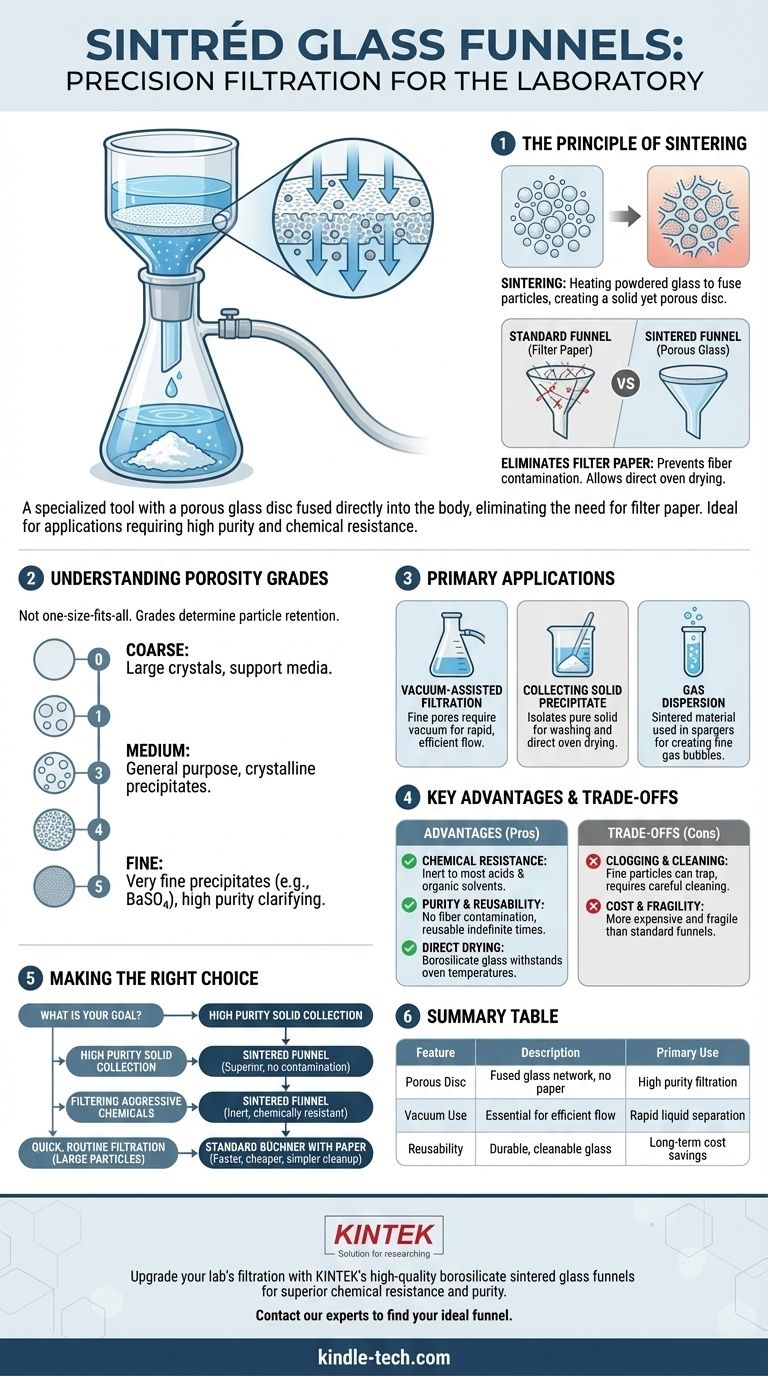

In the laboratory, a sintered glass funnel is a specialized filtration tool used to separate solid particles from a liquid. Unlike a standard funnel that requires filter paper, a sintered funnel has a porous glass disc fused directly into its body, which acts as the filter medium. This design makes it ideal for applications demanding high purity and chemical resistance.

A sintered glass funnel replaces disposable filter paper with a permanent, reusable, and chemically inert porous glass disc. This makes it the superior choice for collecting a pure solid precipitate or for filtering solutions that would degrade paper.

The Principle Behind Sintered Glass

What "Sintered" Means

The term sintering refers to a process where powdered material—in this case, glass—is heated to a temperature where the particles fuse together without fully melting.

This creates a solid, rigid matrix filled with a network of microscopic, interconnected pores. This solid-yet-porous disc is the heart of the funnel.

Eliminating Filter Paper

The primary advantage of this design is the elimination of filter paper. Paper fibers can contaminate the collected solid (precipitate) or the filtered liquid (filtrate).

By integrating the filter directly into the funnel, you ensure a cleaner separation. It also allows the collected solid to be dried in an oven directly on the funnel.

Understanding Porosity Grades

Sintered glass discs are not one-size-fits-all. They are manufactured in different porosity grades, typically numbered from 0 (coarsest) to 5 (finest).

- Coarse grades (0, 1): Used for filtering large crystals or as a support for other filter media.

- Medium grades (2, 3): General-purpose filtration for crystalline precipitates.

- Fine grades (4, 5): Used for capturing very fine precipitates, such as barium sulfate, or for clarifying liquids to a high degree of purity.

Choosing the correct porosity is critical. A grade that is too coarse will let particles pass through, while one that is too fine will be slow and prone to clogging.

How Sintered Funnels Are Used

Vacuum-Assisted Filtration

Sintered glass funnels, often in the shape of a Büchner or Hirsch funnel, are almost always used with a vacuum flask.

The fine pores of the glass disc create significant resistance to flow. Applying a vacuum beneath the funnel pulls the liquid through the disc much more rapidly and efficiently than gravity alone.

Collecting a Solid Precipitate

The most common application is to isolate a solid product from a reaction mixture. The solid is trapped on the surface of the disc, where it can be washed with a solvent to remove impurities.

Because the funnel is made entirely of borosilicate glass, it (and the collected solid) can be placed in an oven for drying.

Gas Dispersion

While the funnel form is for filtration, the sintered glass material itself is also used for gas dispersion. A tube with a sintered disc on the end, known as a gas dispersion tube or "sparger," is used to bubble gas through a liquid, creating very fine bubbles for efficient absorption.

Understanding the Trade-offs

Advantage: Chemical Resistance

Glass is highly inert and resistant to attack from acids, organic solvents, and other aggressive chemicals that would destroy filter paper. The main exceptions are hydrofluoric acid and strong, hot alkali solutions.

Advantage: Purity and Reusability

A properly cleaned sintered funnel can be reused indefinitely, reducing waste and cost over time. More importantly, it eliminates the risk of fiber contamination, ensuring the highest purity for your sample.

Disadvantage: Clogging and Cleaning

This is the primary drawback. Very fine particles can become permanently lodged deep within the porous disc, rendering the funnel useless.

Cleaning requires care, often involving backflushing with a solvent or soaking in strong cleaning solutions (like nitric acid or "aqua regia") to dissolve trapped residues. Aggressive cleaning can damage the disc over time.

Disadvantage: Cost and Fragility

Sintered glassware is significantly more expensive than a simple porcelain funnel and a pack of filter paper. As with all glassware, it is fragile and must be handled with care.

Making the Right Choice for Your Goal

When deciding on a filtration method, your goal determines the best tool.

- If your primary focus is collecting a pure, uncontaminated solid: A sintered glass funnel is the superior choice to avoid any contamination from paper fibers.

- If your primary focus is filtering aggressive or reactive chemicals: The inert nature of glass makes a sintered funnel essential where filter paper would degrade.

- If your primary focus is quick, routine filtration of large particles: A standard Büchner funnel with filter paper is often faster, cheaper, and involves a much simpler cleanup.

Ultimately, selecting a sintered glass funnel is a decision for precision, purity, and chemical compatibility in your filtration work.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Separating solid particles from a liquid under vacuum. |

| Key Advantage | Eliminates filter paper, ensuring high purity and chemical resistance. |

| Porosity Grades | Range from coarse (0) for large crystals to fine (5) for fine precipitates. |

| Ideal For | Collecting pure solid precipitates, filtering aggressive chemicals, and gas dispersion. |

| Maintenance | Requires careful cleaning to prevent clogging; reusable and durable. |

Upgrade your lab's filtration capabilities with KINTEK!

Are you working with sensitive samples or aggressive chemicals that demand the highest purity? KINTEK's sintered glass funnels are crafted from high-quality borosilicate glass, offering superior chemical resistance and eliminating the risk of contamination from filter paper fibers. Our range of porosity grades ensures you have the perfect tool for every application, from coarse particle collection to fine precipitate filtration.

As your trusted partner in laboratory equipment, KINTEK specializes in providing reliable, precision instruments that enhance your research outcomes. Let us help you achieve cleaner separations and more reliable results.

Contact our filtration experts today to find the ideal sintered glass funnel for your specific laboratory needs!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- Why use zirconia grinding jars and balls for halide solid-state electrolytes? Ensuring Absolute Material Purity

- Why are zirconia grinding jars necessary for solid electrolyte powders? Ensure High Purity & Ionic Conductivity

- Why are high-strength graphite molds used for vacuum hot pressing copper composites? Essential Benefits for Lab Results

- Why is a magnetic stirrer utilized at specific rotation speeds in flocculation? Optimize Particle Growth Efficiency

- What is the function of a PID temperature control system? Ensure Stability in Nuclear Simulations

- Why is an industrial-grade ultrasonic cleaner required for LDH conversion? Ensure Pure Crystal Growth & Adhesion

- What does a furnace air pressure switch do? Prevent Dangerous Gas Buildup in Your Home