At its core, a sputtering tool is a highly specialized piece of equipment that operates under a high vacuum to deposit exceptionally thin and uniform layers of material onto a surface. This process, known as sputter deposition, is not about melting or evaporating material; instead, it uses a physical mechanism to precisely transfer atoms from a source (the "target") to a destination (the "substrate").

A sputtering tool functions like a subatomic sandblaster. It uses high-energy ions in a vacuum to physically knock atoms off a source material, which then travel and deposit as a highly controlled, ultra-thin film onto another object.

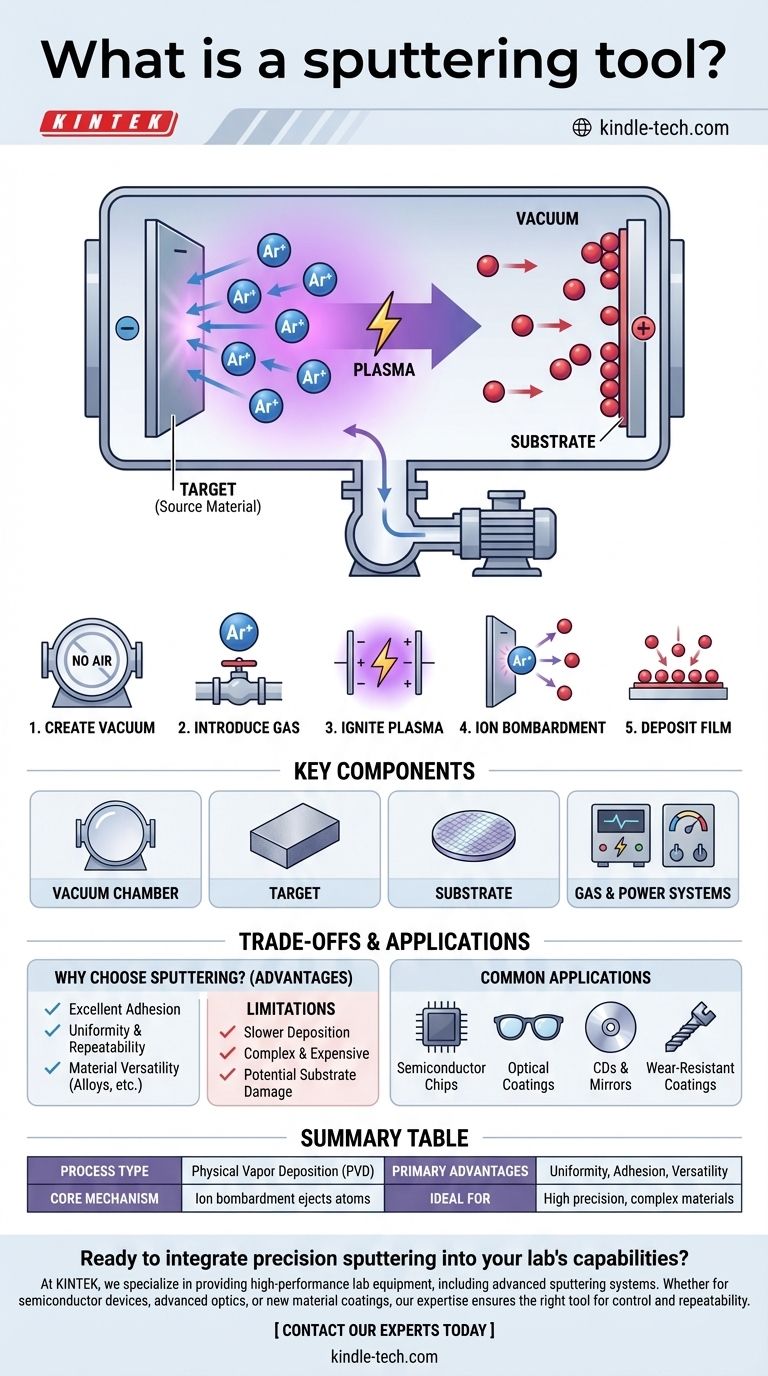

How Sputtering Works: From Plasma to Thin Film

The sputtering process is a type of Physical Vapor Deposition (PVD) that relies on a series of carefully controlled physical steps to build a film, one atom at a time.

Step 1: Creating the Vacuum

The entire process must occur in a high-vacuum chamber. This is non-negotiable, as it removes air and other particles that would otherwise collide with the sputtered atoms and contaminate the final film.

Step 2: Introducing the Sputtering Gas

A small, precisely controlled amount of an inert gas, typically Argon (Ar), is introduced into the vacuum chamber. This gas will become the "blasting media."

Step 3: Igniting the Plasma

A strong electric field is applied within the chamber. The material to be deposited (the target) is given a negative charge (becoming a cathode), while the substrate holder or chamber walls act as the positive charge (anode). This high voltage ignites the Argon gas, stripping electrons from its atoms and creating a visible glow of ionized gas known as a plasma.

Step 4: Ion Bombardment

The positively charged Argon ions (Ar+) within the plasma are now powerfully accelerated toward the negatively charged target. They collide with the target surface with significant kinetic energy.

Step 5: Deposition on the Substrate

This high-energy bombardment physically knocks out, or "sputters," atoms from the target material. These ejected atoms travel through the vacuum and land on the substrate, gradually building up a thin, uniform, and dense film.

Key Components of a Sputtering System

While designs vary, all sputtering tools share several fundamental components that enable this precise process.

The Vacuum Chamber

This is the sealed enclosure where the deposition takes place. It's connected to a series of powerful pumps capable of removing nearly all the air to create the necessary high-vacuum environment.

The Target (Source Material)

This is a block or plate made of the material you wish to deposit. It can be a pure metal, an alloy, or even a ceramic compound. The target serves as the source of the coating atoms.

The Substrate

This is the object or wafer that receives the coating. It is carefully positioned inside the chamber to ensure it is coated evenly by the sputtered atoms.

The Gas and Power Systems

A gas handling system controls the precise flow of Argon into the chamber. A high-voltage power supply—either Direct Current (DC) for conductive targets or Radio Frequency (RF) for non-conductive (insulating) targets—provides the energy to create and sustain the plasma.

Understanding the Trade-offs and Applications

Sputtering is chosen for specific reasons and is a cornerstone technology in many advanced industries.

Why Choose Sputtering?

The primary advantage of sputtering is control. It produces films with excellent adhesion to the substrate, exceptional uniformity over large areas, and highly repeatable thickness. It can also be used to deposit complex materials like alloys without altering their chemical composition.

Common Applications

You can find sputtered films everywhere in modern technology. They are used to create the microscopic metal wiring in semiconductor chips, apply anti-reflective coatings on eyeglass lenses, produce the reflective layers on CDs and mirrors, and apply hard, wear-resistant coatings on cutting tools.

Limitations to Consider

Sputtering is generally a slower deposition process compared to alternatives like thermal evaporation. The equipment is also complex and expensive. Furthermore, the high-energy nature of the ion bombardment can sometimes cause damage to very delicate or sensitive substrates.

Making the Right Choice for Your Goal

Understanding the core strengths of sputtering helps clarify its role in manufacturing and research.

- If your primary focus is precision and film quality: Sputtering is the superior choice for creating dense, highly adherent films with excellent thickness control, essential for optics and electronics.

- If your primary focus is material versatility: The ability to deposit alloys, compounds, and insulators (using RF power) makes sputtering more flexible than methods limited to pure, low-melting-point metals.

- If your primary focus is high-speed deposition of simple metals: You might investigate thermal evaporation, which can be a faster and less complex process for certain applications.

Ultimately, the sputtering tool is an indispensable instrument for engineering materials at the atomic scale, enabling the performance of countless high-tech products.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Ion bombardment of a target material to eject atoms |

| Primary Advantages | Excellent film uniformity, adhesion, and material versatility |

| Common Applications | Semiconductor metallization, optical coatings, wear-resistant layers |

| Ideal For | Applications requiring high precision and complex material deposition |

Ready to integrate precision sputtering into your lab's capabilities?

At KINTEK, we specialize in providing high-performance lab equipment, including advanced sputtering systems, to meet the exacting demands of modern research and development. Whether you are working on semiconductor devices, advanced optics, or new material coatings, our expertise ensures you get the right tool for unparalleled control and repeatability.

Let's discuss how a KINTEK sputtering solution can enhance your thin-film processes. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the critical parameters for high-quality CVD graphene? Optimize Your Synthesis Process

- What is low power chemical vapor deposition? Discover LPCVD for Superior Thin-Film Quality

- What is the principle of CVD process? Growing High-Performance Materials from Gas

- What is the atmospheric pressure CVD process? A Guide to High-Purity Thin Film Deposition

- What is chemical vapor deposition CVD in semiconductor? The Key to Modern Microchip Fabrication

- What is the energy of sputtered atoms? Master the Key to Superior Thin Film Quality

- What are the methods used to deposit thin films? A Guide to Physical vs. Chemical Deposition

- How to manufacture CVD diamond? A Guide to Growing Lab-Created Diamonds