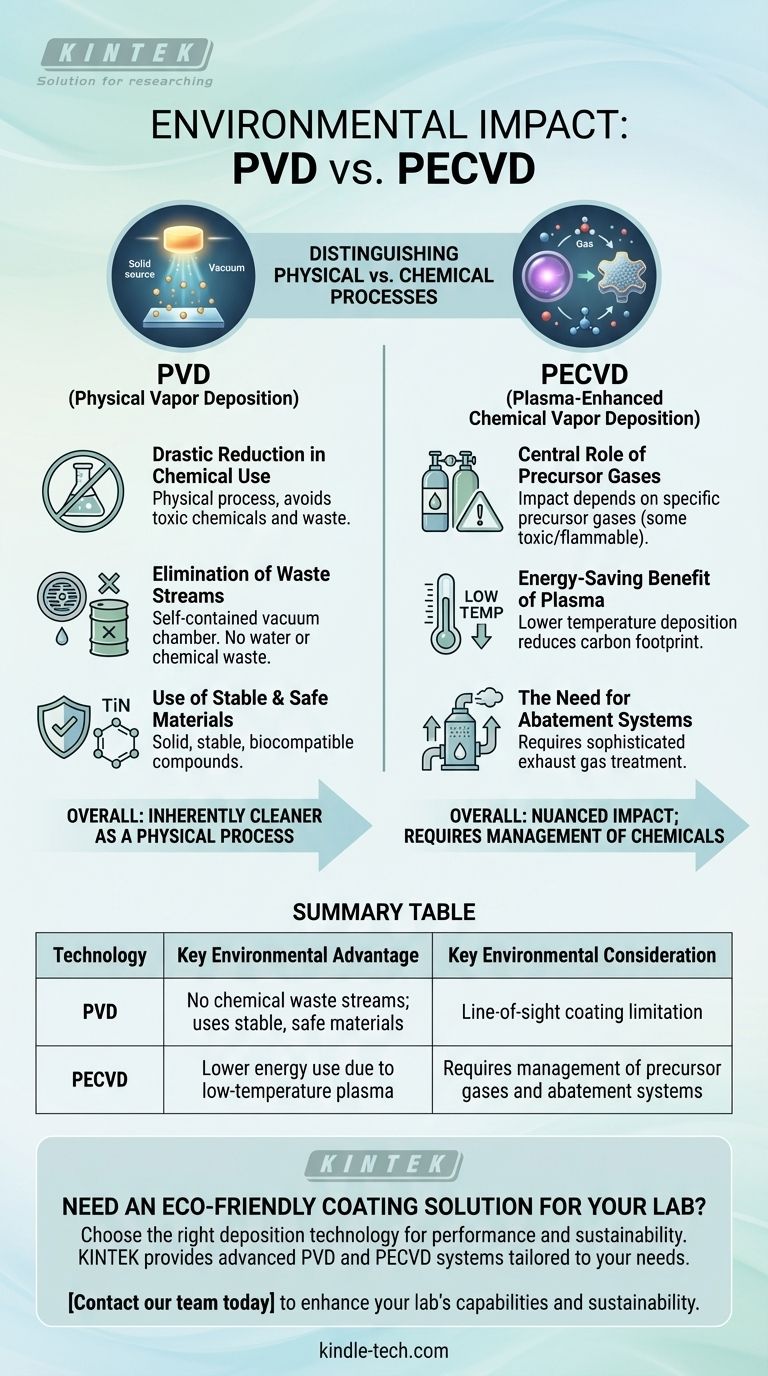

At first glance, it is crucial to distinguish between PVD (Physical Vapor Deposition) and PECVD (Plasma-Enhanced Chemical Vapor Deposition), as their environmental impacts differ significantly. PVD is widely considered environmentally friendly because it is a physical process that avoids the toxic chemicals and waste streams common in traditional plating. PECVD, while often cleaner than older methods, is a chemical process whose environmental friendliness depends heavily on the specific precursor gases used and the systems in place to manage them.

The environmental benefit of modern vapor deposition techniques primarily comes from their vast improvement over traditional wet chemical processes like electroplating. However, PVD is inherently cleaner as a physical process, while the environmental impact of PECVD is more nuanced and tied to its chemical nature.

The Environmental Case for PVD (Physical Vapor Deposition)

Many discussions about "eco-friendly coating" reference PVD. It stands as a clean alternative to legacy methods for several clear reasons.

Drastic Reduction in Chemical Use

The most significant benefit of PVD is that it is a physical process, not a chemical one. It works by vaporizing a solid source material in a vacuum and depositing it atom by atom onto a substrate.

This completely avoids the use of hazardous acids, cyanides, and toxic metal solutions required for traditional methods like electroplating.

Elimination of Waste Streams

Processes like electroplating and painting generate significant liquid chemical waste and volatile organic compounds (VOCs) that require complex and costly treatment.

PVD, by contrast, occurs in a self-contained vacuum chamber. It produces no water waste, releases no harmful gases, and leaves behind no other polluting residues.

Use of Stable and Safe Materials

The materials used for PVD coating, such as Titanium Nitride (TiN) and Chromium Nitride (CrN), are solid, stable, and biocompatible compounds.

This contrasts with wet plating, which involves solutions of heavy metals that pose a direct environmental and health risk. Furthermore, PVD coatings do not degrade or require top coats that could pollute over time.

The Nuanced Environmental Profile of PECVD

PECVD is a type of Chemical Vapor Deposition. While the "plasma-enhanced" aspect provides an environmental advantage, its reliance on chemical reactions makes its profile more complex than PVD.

The Central Role of Precursor Gases

Unlike PVD, which vaporizes a solid, PECVD creates a film by introducing volatile precursor gases into a chamber and using plasma to drive a chemical reaction.

The environmental impact hinges entirely on these precursors. Some are relatively benign, but many can be toxic, flammable, corrosive, or potent greenhouse gases (e.g., silane, ammonia, fluorine-based gases).

The Energy-Saving Benefit of Plasma

The key advantage of the "plasma" in PECVD is that it allows deposition to occur at much lower temperatures than traditional CVD.

Lowering process temperatures directly translates to significant energy savings, reducing the carbon footprint of the manufacturing operation. This is a primary environmental benefit of the technique.

The Need for Abatement Systems

Because PECVD involves chemical reactions with potentially hazardous precursors, it generates chemical byproducts and unreacted gases that must be managed.

Properly engineered PECVD systems require sophisticated exhaust gas treatment systems, known as abatement systems. These scrubbers neutralize harmful effluents before they are released into the atmosphere, but they add complexity and cost to the process.

Understanding the Trade-offs

Choosing between these technologies involves balancing process capability with environmental and safety management.

PVD: Mechanically Simple, Environmentally Clean

PVD is a line-of-sight process, meaning it works best on surfaces with direct exposure to the vapor source. Its primary advantage is its environmental simplicity; what you put in is what you get out, with no chemical reactions to manage.

PECVD: Chemically Complex, Highly Versatile

PECVD is not line-of-sight and can conformally coat highly complex, three-dimensional shapes. This versatility comes at the cost of managing complex and sometimes hazardous gas chemistries and their byproducts. The process is only "green" if the required safety and abatement systems are implemented correctly.

Making the Right Choice for Your Application

Your choice must be guided by both the technical requirements of the coating and your capacity for managing the associated process chemistry.

- If your primary focus is maximum environmental safety and process simplicity: PVD is the superior choice, as it avoids reactive chemical precursors and waste streams entirely.

- If your primary focus is coating complex geometries at low temperatures: PECVD is often the only viable option, but you must budget for the necessary gas handling and exhaust abatement systems to ensure safe and responsible operation.

Ultimately, understanding the fundamental difference between a physical and a chemical process is key to making an informed decision about your coating technology.

Summary Table:

| Technology | Key Environmental Advantage | Key Environmental Consideration |

|---|---|---|

| PVD | No chemical waste streams; uses stable, safe materials | Line-of-sight coating limitation |

| PECVD | Lower energy use due to low-temperature plasma | Requires management of precursor gases and abatement systems |

Need an eco-friendly coating solution for your lab?

Choosing the right deposition technology is critical for both performance and sustainability. At KINTEK, we specialize in providing advanced lab equipment, including PVD and PECVD systems, tailored to meet your specific research and production needs while prioritizing environmental responsibility.

Our experts can help you navigate the trade-offs between process capability and environmental impact to find the perfect solution for your application. Let us help you achieve superior results with a cleaner, more efficient process.

Contact our team today to discuss your project and discover how KINTEK's solutions can enhance your lab's capabilities and sustainability.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition