At its core, a vacuum system for sputtering is a highly controlled environment engineered to achieve two distinct and critical pressure states. It first creates an ultra-clean, high-vacuum condition to remove contaminants and then introduces a precise, low-pressure gas atmosphere in which the sputtering process can actually take place.

The central purpose of a sputtering vacuum system is not simply to remove air, but to first create a pristine environment free of reactive gases and then to establish a stable, controlled plasma from a high-purity sputter gas. The quality of your final film is determined by how well the system manages this two-stage process.

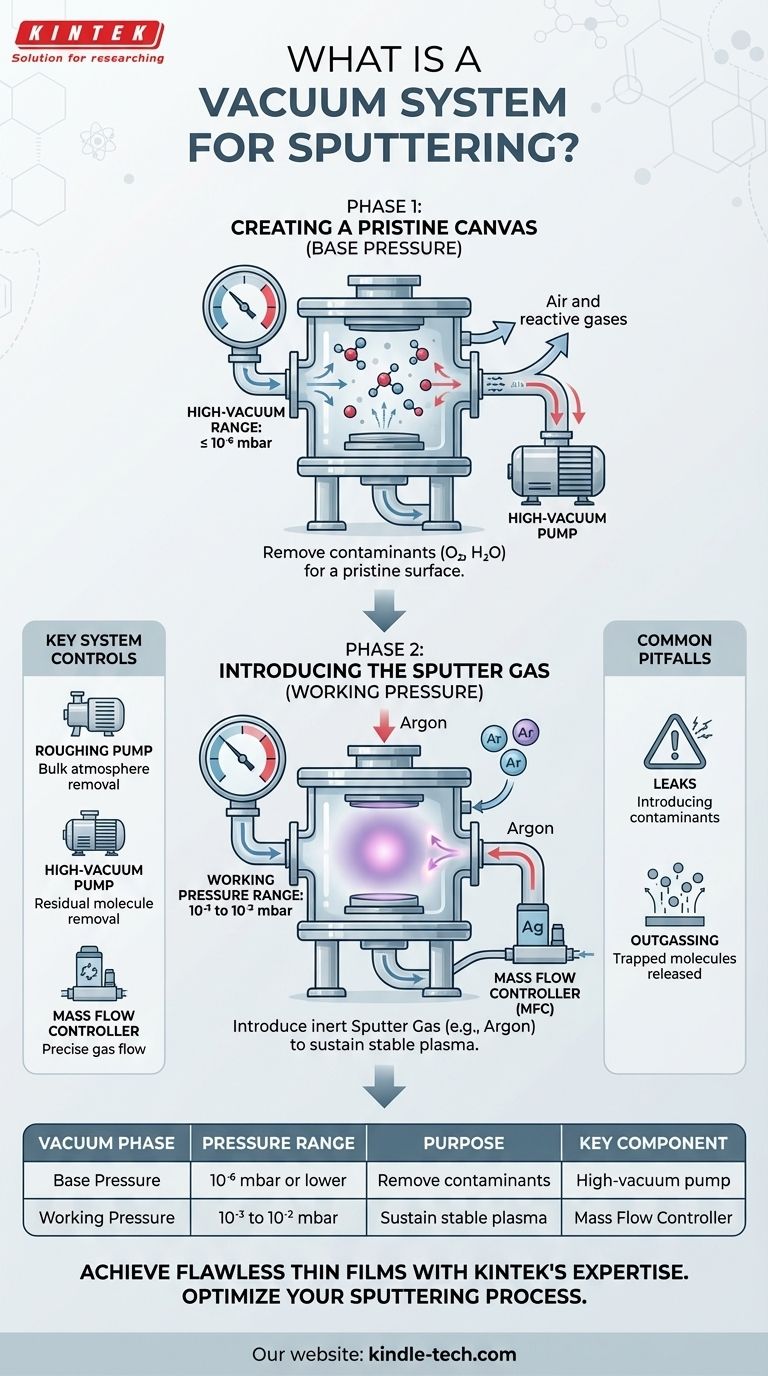

The Two-Phase Pressure Environment

The entire sputtering process hinges on the vacuum system's ability to create and transition between two fundamentally different environments inside the chamber: the base pressure and the working pressure.

The Base Pressure: Creating a Pristine Canvas

The initial step is to pump the chamber down to a base pressure. This is the lowest pressure achieved before introducing any process gas.

For quality sputtering, this needs to be in the high-vacuum range (10⁻⁶ mbar or lower). The goal is to remove as many residual gas molecules as possible—especially reactive ones like oxygen and water vapor.

Failing to reach a sufficient base pressure means these contaminants will be incorporated into your depositing film, compromising its purity, density, and performance.

The Working Pressure: Introducing the Sputter Gas

Once a clean base vacuum is achieved, a high-purity, inert sputter gas (typically Argon) is bled into the chamber.

This raises the pressure to a higher level known as the working pressure, usually in the millitorr range (10⁻³ to 10⁻² mbar).

This pressure is high enough to sustain a stable plasma—the ionized gas required to bombard the target material—but low enough to allow sputtered atoms to travel to the substrate with minimal interference.

Key System Functions and Controls

A sputtering vacuum system is more than just a pump and a chamber. It requires precise control over the gas environment to ensure repeatable results.

Pumping Down to High Vacuum

Reaching the necessary base pressure requires a sophisticated pumping system. This typically involves a roughing pump to remove the bulk of the atmosphere, followed by a high-vacuum pump (like a turbomolecular or cryogenic pump) to remove the remaining molecules.

Managing Gas Flow

The working pressure is maintained by a mass flow controller (MFC). This device precisely meters the amount of sputter gas entering the chamber, measured in standard cubic centimeters per minute (sccm).

This constant, controlled flow ensures the plasma remains stable throughout the deposition, which is critical for achieving uniform film thickness and properties.

Common Pitfalls to Avoid

Understanding the potential issues with a vacuum system is key to troubleshooting and achieving high-quality results.

The Impact of Leaks

Even a microscopic leak in the chamber can prevent the system from reaching its target base pressure. This constantly introduces atmospheric contaminants, directly compromising the purity of the deposited film.

The Problem of Outgassing

Materials inside the chamber, including the chamber walls themselves, can trap and later release molecules (especially water vapor). This phenomenon, called outgassing, can be a major source of contamination and can significantly increase the time it takes to reach base pressure.

Making the Right Choice for Your Goal

The quality of your vacuum system directly dictates the quality of your thin film. The specific vacuum parameters you need depend entirely on your application.

- If your primary focus is high-purity electronic or optical films: You must prioritize achieving the lowest possible base pressure (10⁻⁷ mbar or better) to minimize contamination from reactive gases.

- If your primary focus is high-throughput production of simpler metallic coatings: A slightly higher base pressure might be acceptable, allowing for faster cycle times by reducing the initial pump-down period.

Ultimately, mastering your vacuum environment is the first and most critical step toward mastering the sputtering process itself.

Summary Table:

| Vacuum Phase | Pressure Range | Purpose | Key Component |

|---|---|---|---|

| Base Pressure | 10⁻⁶ mbar or lower | Remove contaminants (O₂, H₂O) for a pristine starting surface. | High-vacuum pump (e.g., Turbomolecular) |

| Working Pressure | 10⁻³ to 10⁻² mbar | Introduce sputter gas (e.g., Argon) to sustain a stable plasma. | Mass Flow Controller (MFC) |

Achieve flawless thin films with a vacuum system tailored to your sputtering application. Whether your priority is ultra-high purity for R&D or high-throughput for production, KINTEK's expertise in lab equipment ensures you get the precise vacuum environment you need. Contact our experts today to discuss your specific requirements and how we can optimize your sputtering process for superior results.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

People Also Ask

- Which material is suitable for hardening? The Critical Role of Carbon Content in Steel Selection

- What role do high-temperature industrial furnaces play in PGM recovery? Maximize Platinum Yield with Precision Heat

- What happens when a material is annealed? A Guide to Softer, More Workable Materials

- How does a vacuum environment benefit the purification of matrix powders? Optimize Diamond Tool Sintering Efficiency

- What are the uses of heat treated aluminum alloys? Unlock High-Strength, Lightweight Performance

- What is the pressure on a vacuum furnace? Mastering the Key to Process Purity and Quality

- Why are glove boxes or vacuum equipment indispensable for ZrO2-Li2ZrCl6 preparation? Protect Air-Sensitive Materials

- What material is used in a high temperature furnace? A Guide to Refractory Metals & Ceramics