In semiconductor manufacturing, a vertical diffusion furnace is a specialized high-temperature chamber used to precisely alter the electrical properties of silicon wafers. It does this by enabling diffusion, a process where impurity atoms, known as dopants, move from a gas vapor into the solid silicon wafer. This step is fundamental for creating the functional components, like transistors, that make up an integrated circuit.

A vertical diffusion furnace is more than just an oven; it is a precision-controlled environment engineered for atomic-level uniformity and cleanliness. Its vertical orientation is a critical design choice that minimizes particle contamination and improves thermal consistency, solving key challenges in mass-producing reliable microchips.

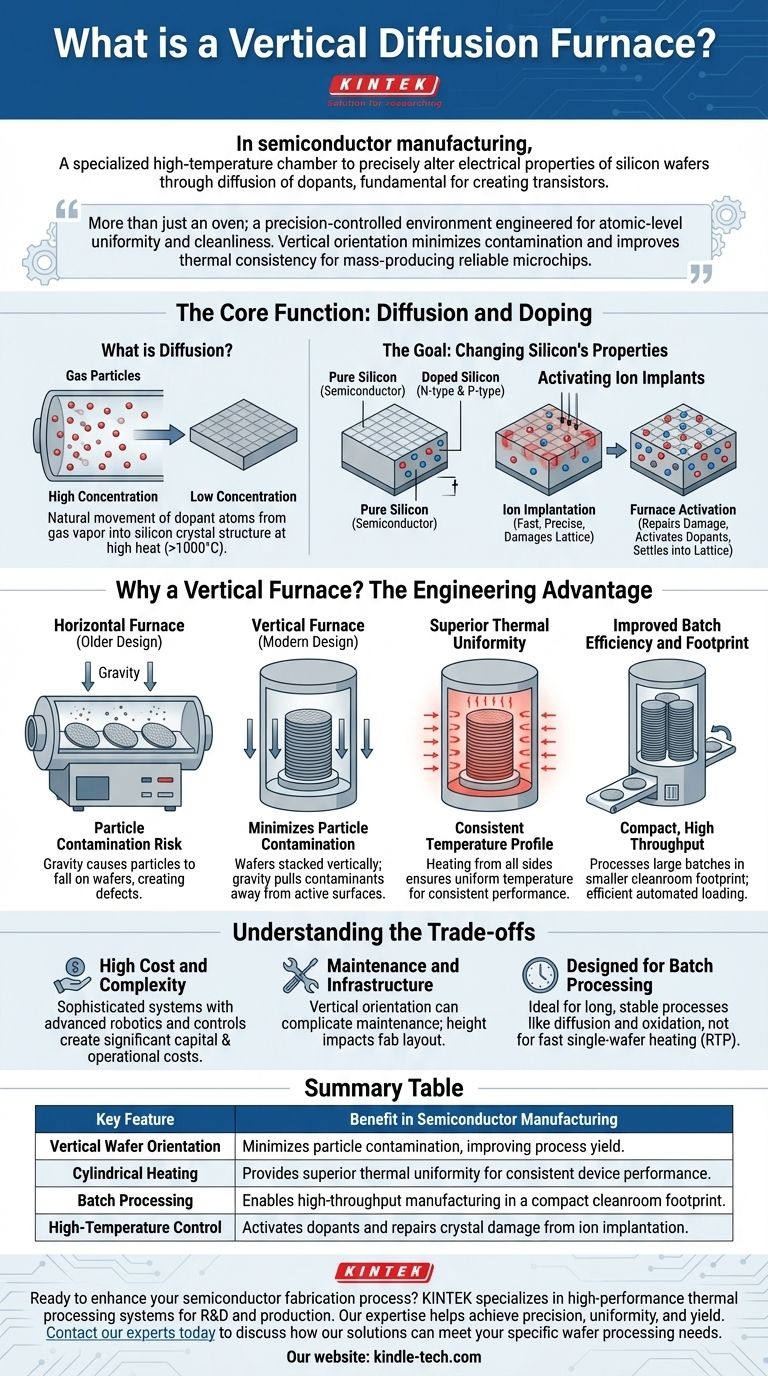

The Core Function: Diffusion and Doping

Diffusion is a cornerstone process in chip fabrication. The furnace creates the high-temperature environment needed for it to occur in a controlled manner.

What is Diffusion?

Diffusion is the natural movement of particles from an area of high concentration to an area of low concentration. In the context of a furnace, dopant atoms in a gas are driven by high heat (often exceeding 1000°C) to spread out and integrate themselves into the silicon wafer's crystal structure.

The Goal: Changing Silicon's Properties

Pure silicon is a semiconductor, meaning it doesn't conduct electricity well on its own. By introducing specific impurities (dopants) like boron or phosphorus, we can change its behavior. This "doping" process creates N-type (negative) and P-type (positive) regions, which are the essential building blocks of transistors.

Activating Ion Implants

Often, dopants are first introduced into the wafer using a process called ion implantation, where ions are physically shot into the silicon surface. This method is fast and precise but damages the silicon's crystal lattice.

The diffusion furnace performs the critical follow-up step. The high heat serves two purposes: it repairs the crystal damage and "activates" the dopants, allowing them to settle into the lattice and become electrically active.

Why a Vertical Furnace? The Engineering Advantage

The shift from older horizontal furnaces to modern vertical ones was driven by the need for greater precision and higher yields as chips became more complex.

Minimizing Particle Contamination

This is the primary advantage. In a horizontal tube, gravity can cause microscopic particles from the tube's ceiling to fall onto the wafers below, creating defects. In a vertical furnace, wafers are stacked vertically. Gravity works with the design, pulling any potential contaminants down and away from the active wafer surfaces.

Superior Thermal Uniformity

Heating a stack of wafers from all sides in a vertical cylinder creates a more uniform thermal environment. This ensures that every wafer—and every chip on each wafer—experiences the exact same temperature profile, leading to highly consistent and predictable electrical performance.

Improved Batch Efficiency and Footprint

Vertical furnaces can process a large batch of wafers (a "boat") in a smaller cleanroom footprint compared to their horizontal counterparts. Wafers are loaded into the boat from the bottom and lifted into the sealed process tube, an efficient and automated system that improves throughput.

Understanding the Trade-offs

While dominant in the industry, vertical furnaces have specific characteristics that make them suitable for certain processes but not others.

High Cost and Complexity

These are highly sophisticated and expensive systems. The robotic automation for wafer handling, advanced gas flow controls, and precision temperature management contribute to their significant capital cost and operational complexity.

Maintenance and Infrastructure

The vertical orientation, while good for cleanliness, can make certain maintenance tasks more difficult than on a horizontal system. Their height can also be a consideration for the layout and infrastructure of the fabrication plant (fab).

Designed for Batch Processing

Vertical diffusion furnaces are ideal for long, stable processes that last for hours, like diffusion and oxidation, where an entire batch of wafers is treated identically. They are not suited for processes requiring very fast, single-wafer heating and cooling, which is handled by different equipment like Rapid Thermal Processing (RTP) systems.

Making the Right Choice for Your Goal

Understanding the furnace's function helps contextualize its role in the broader goal of creating a functional semiconductor device.

- If your primary focus is process yield and uniformity: The vertical furnace's key advantage is its ability to minimize particle defects and provide exceptional thermal consistency across large batches.

- If your primary focus is device physics: The furnace is the critical tool that activates dopants and anneals crystal damage, directly defining the final electrical properties of transistors.

- If your primary focus is fab operations and efficiency: The vertical furnace provides high throughput in a compact footprint, making it a cornerstone of modern, high-volume manufacturing.

Ultimately, the vertical diffusion furnace is an indispensable tool in modern chipmaking, enabling the atomic-level precision required to build today's complex integrated circuits.

Summary Table:

| Key Feature | Benefit in Semiconductor Manufacturing |

|---|---|

| Vertical Wafer Orientation | Minimizes particle contamination, improving process yield. |

| Cylindrical Heating | Provides superior thermal uniformity for consistent device performance. |

| Batch Processing | Enables high-throughput manufacturing in a compact cleanroom footprint. |

| High-Temperature Control | Activates dopants and repairs crystal damage from ion implantation. |

Ready to enhance your semiconductor fabrication process?

KINTEK specializes in high-performance lab equipment, including thermal processing systems essential for R&D and production. Our expertise can help you achieve the precision, uniformity, and yield required for advanced chip manufacturing.

Contact our experts today to discuss how our solutions can meet your specific wafer processing needs.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity