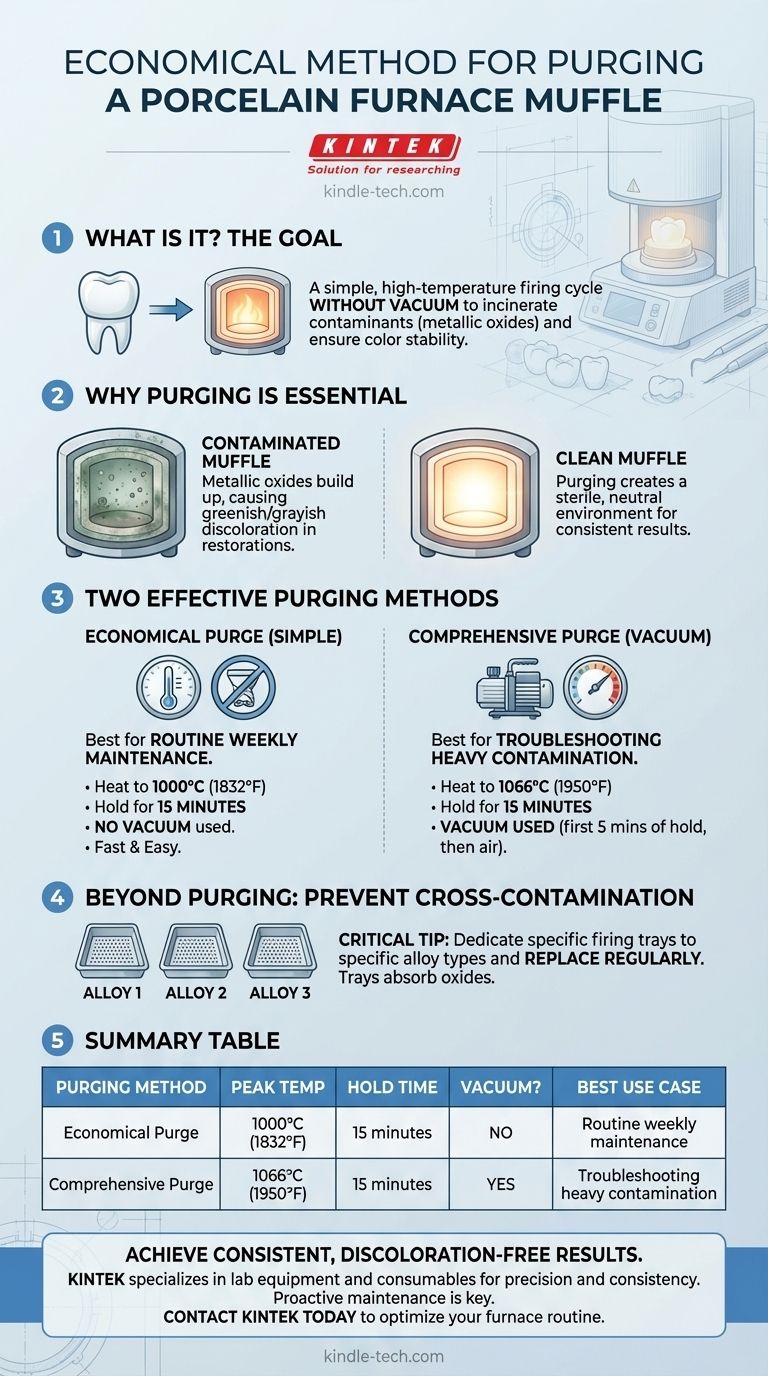

An economical method for purging a porcelain furnace muffle involves a simple, high-temperature firing cycle without a vacuum. This process is designed to burn off metallic oxides and other contaminants that can accumulate over time and discolor your dental restorations.

The core principle of furnace purging is to use a controlled, high-heat cycle to incinerate residual contaminants within the muffle, ensuring the color stability and integrity of subsequent porcelain firings.

Why Purging Your Furnace is Non-Negotiable

A porcelain furnace muffle is the heart of your ceramic restorations. Over time, it inevitably becomes contaminated.

The Problem of Contamination

Every firing cycle, especially with metal-ceramics, releases microscopic metallic oxides. These particles deposit onto the muffle's insulation and firing tray.

This buildup can lead to a greenish or grayish discoloration in new porcelain work, compromising aesthetics and requiring costly remakes. Purging acts as a critical reset for the firing chamber.

The Goal: A Clean Firing Environment

The objective of a purge cycle is to heat the furnace to a temperature high enough to vaporize and burn off these contaminants. This effectively sterilizes the chamber, providing a neutral environment for the next restoration.

Two Effective Purging Methods

There are two primary approaches to purging. One is a straightforward, economical method, while the other is more comprehensive and often involves a vacuum cycle.

The Simple, Economical Purge

This is the most direct and cost-effective method. It relies solely on high heat and ambient air to oxidize and eliminate contaminants.

The process is to run a firing cycle up to 1000°C (1832°F) and hold it at that temperature for 15 minutes. Crucially, this entire cycle should be run without a vacuum.

The Comprehensive Purge (with Vacuum)

For a more thorough cleaning, a cycle incorporating a vacuum can be used. This method helps pull volatile elements out of the muffle before the final air-based oxidation stage.

This cycle typically involves heating from a low temperature (e.g., 538°C / 1000°F) to a peak temperature of 1066°C (1950°F) under a full vacuum. Once the peak temperature is reached, it is held for 15 minutes. The vacuum is released after the first 5 minutes of the hold, allowing the final 10 minutes to occur in air.

Understanding the Trade-offs

While both methods are effective, they serve slightly different purposes. The simple, economical purge is excellent for routine weekly maintenance. It is fast, easy to program, and requires no special materials.

The comprehensive purge is better suited for situations where you suspect heavy contamination or are experiencing persistent discoloration issues. The vacuum stage provides a deeper cleaning, but the cycle is more complex to program and takes longer.

Beyond Purging: Preventing Cross-Contamination

Purging cleans the muffle, but it doesn't solve issues with contaminated equipment. The single biggest source of recurring contamination is the firing tray.

The Importance of Firing Trays

Firing trays and pegs absorb oxides from every case. Using the same tray for different types of alloys, or for too long, will inevitably lead to cross-contamination.

It is highly advisable to dedicate specific trays to specific alloy types and to replace your firing trays on a regular basis. This simple habit can prevent more problems than frequent purging can solve.

Making the Right Choice for Your Lab

Your purging strategy should be based on your lab's workload and the materials you use.

- If your primary focus is routine maintenance: Perform the simple, economical purge (1000°C for 15 minutes, no vacuum) on a weekly basis.

- If you are troubleshooting discoloration issues: Run the comprehensive purge cycle with a vacuum and immediately replace your firing trays.

Proactive maintenance is the key to achieving consistent, high-quality results from your porcelain furnace.

Summary Table:

| Purging Method | Peak Temperature | Hold Time | Vacuum Used? | Best Use Case |

|---|---|---|---|---|

| Economical Purge | 1000°C (1832°F) | 15 minutes | No | Routine weekly maintenance |

| Comprehensive Purge | 1066°C (1950°F) | 15 minutes | Yes | Troubleshooting heavy contamination |

Achieve Consistent, Discoloration-Free Results

Your porcelain furnace is a critical investment in your lab's quality and reputation. Regular purging with the right equipment is essential for protecting that investment.

At KINTEK, we specialize in the lab equipment and consumables that dental laboratories rely on for precision and consistency. From high-performance porcelain furnaces to dedicated firing trays that prevent cross-contamination, we provide the tools for success.

Let our experts help you optimize your furnace maintenance routine. Contact KINTEK today to discuss your lab's specific needs and ensure every restoration meets your highest standards.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do high-temperature furnaces and ceramic crucibles impact Li-ion battery stability? Master Precision Synthesis

- What is the use of electric muffle furnace? Achieve Pure, High-Temperature Processing

- What is the use of furnace in laboratory? Unlock Material Transformation for Your Research

- What is the use of high temperature muffle furnace? Achieve Pure, Contamination-Free Thermal Processing

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing