At its core, a digital muffle furnace is a high-temperature chamber used for a vast range of material processing and analysis tasks. Its primary function is to heat a sample in a controlled environment up to 1200°C or higher, making it essential for applications like ashing materials, heat-treating metals, and sintering ceramics. The "digital" aspect signifies the use of a microprocessor for precise, repeatable temperature control, which is critical for modern scientific and industrial work.

The defining feature of a muffle furnace is not just its high heat, but its "muffle"—an inner chamber that isolates the sample from the heating elements. This design prevents contamination, ensuring the integrity of the process, whether for precise chemical analysis or creating a flawless material.

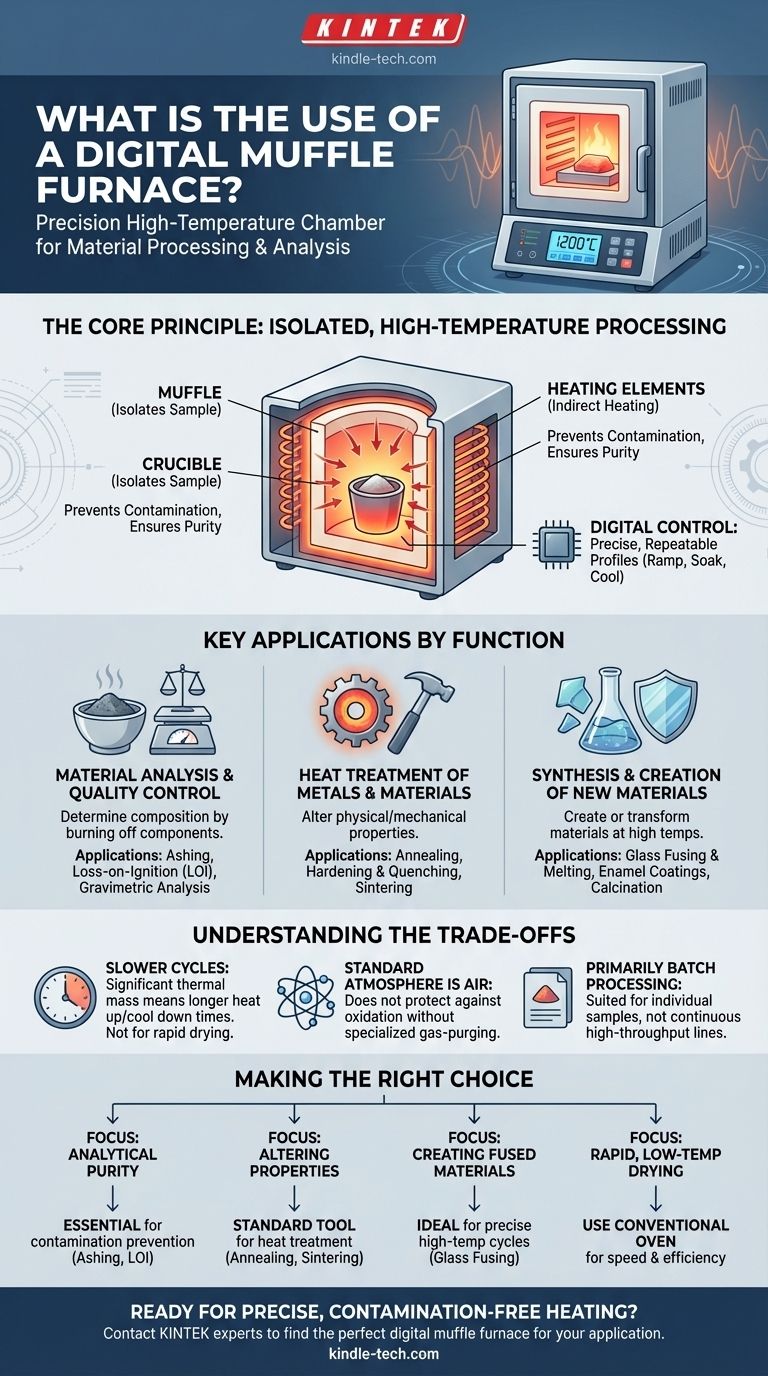

The Core Principle: Isolated, High-Temperature Processing

To truly understand a muffle furnace's use, you must first grasp its fundamental design advantage over a simple oven. The value lies in the separation between the heat source and the material being processed.

What "Muffle" Means

The term "muffle" refers to the furnace's inner lining, typically made of a high-temperature ceramic. This chamber contains the sample. The heating elements (coils) are positioned on the outside of this muffle.

Heat radiates through the muffle walls to heat the sample inside. This indirect heating is the furnace's key operational principle.

Why Isolation Matters

This separation is crucial because it prevents contamination. In furnaces where a flame or exposed electric coils are used, byproducts of combustion or material flaking from the elements can get into the sample.

By isolating the sample, a muffle furnace ensures that any changes observed—like weight loss during ashing—are due only to the sample itself and the controlled heat, not outside interference. This is non-negotiable for analytical accuracy.

The Role of Digital Control

Older furnaces used analog dials, which were imprecise. Digital controllers allow you to program exact temperature profiles.

This means you can set a specific ramp rate (how fast it heats up), a "soak" time (how long it stays at a target temperature), and a controlled cooling rate. This repeatability is essential for quality control and reliable scientific research.

Key Applications by Function

The combination of high, clean heat and precise control makes the muffle furnace a versatile tool across many industries. Its uses can be grouped into three main categories.

Material Analysis and Quality Control

This is one of the most common uses in laboratory settings. The goal is to determine the composition of a sample by burning off its organic or volatile components.

Applications include:

- Ashing: Determining the non-combustible mineral content in a sample, such as in food, coal, or plastics.

- Loss-on-Ignition (LOI): Measuring the weight change in a sample after being heated to a high temperature, common in soil science and cement analysis.

- Gravimetric Analysis: A quantitative method where the mass of a substance is measured after a controlled thermal event.

Heat Treatment of Metals and Materials

In metallurgy and materials science, heat is used to intentionally alter a material's physical and mechanical properties, such as its hardness or ductility.

Applications include:

- Annealing: Heating and slowly cooling a metal to soften it and relieve internal stresses.

- Hardening & Quenching: Heating steel to a critical temperature and then rapidly cooling it to increase its hardness.

- Sintering: Heating powdered materials (like ceramics or metals) below their melting point until their particles bond together, forming a solid, dense object.

Synthesis and Creation of New Materials

Muffle furnaces are also used as reactors to create or transform materials at high temperatures.

Applications include:

- Glass Fusing & Melting: Creating artistic or technical glass objects by melting different pieces of glass together.

- Enamel Coatings: Fusing a layer of powdered glass onto a metal substrate to create a durable, protective coating.

- Calcination: Decomposing a material or driving off volatile substances, often as a step in creating cements or catalysts.

Understanding the Trade-offs

While incredibly useful, a muffle furnace is not the right tool for every heating job. Understanding its limitations is key to using it effectively.

Slower Heating and Cooling Cycles

The ceramic muffle that provides insulation and isolation also has significant thermal mass. This means muffle furnaces heat up and cool down much more slowly than a standard laboratory oven. They are inefficient for simple, low-temperature drying tasks.

Standard Atmosphere is Air

A basic muffle furnace operates with an ambient air atmosphere. While the muffle prevents contamination from the heating elements, it does not protect the sample from oxidation by the air inside the chamber.

Processes that require an inert atmosphere (like nitrogen or argon) need a specialized, and more expensive, furnace with gas-purging capabilities.

Primarily for Batch Processing

Most muffle furnaces are designed for processing individual samples or small batches. They are not typically suited for continuous, high-throughput industrial production lines, which would require larger, custom-built furnace systems.

Making the Right Choice for Your Task

Deciding if a muffle furnace fits your need comes down to a few key questions about your goal.

- If your primary focus is analytical purity: A muffle furnace is essential for applications like ashing or loss-on-ignition where preventing contamination is paramount to accurate results.

- If your primary focus is altering material properties: It is the standard tool for heat-treating metals (annealing, hardening) or creating ceramics through sintering.

- If your primary focus is creating fused materials: It is ideal for processes like glass fusing or applying enamel coatings that require precise, repeatable high-temperature cycles.

- If your primary focus is rapid, low-temperature drying: A conventional laboratory or convection oven is a much faster and more energy-efficient choice.

Ultimately, you choose a muffle furnace when your process demands clean, precise, and repeatable high-temperature heating.

Summary Table:

| Key Feature | Primary Benefit | Common Applications |

|---|---|---|

| Isolated Muffle Chamber | Prevents sample contamination | Ashing, Loss-on-Ignition, Gravimetric Analysis |

| Digital Temperature Control | Ensures precise, repeatable heating cycles | Annealing, Hardening, Sintering |

| High-Temperature Capability (up to 1200°C+) | Enables material synthesis and transformation | Glass Fusing, Enamel Coating, Calcination |

Ready to enhance your lab's capabilities with precise, contamination-free heating?

KINTEK specializes in high-performance digital muffle furnaces and lab equipment, designed to meet the rigorous demands of analytical chemistry, metallurgy, and materials science. Our furnaces provide the accurate temperature control and sample isolation you need for reliable ashing, heat treatment, and sintering processes.

Contact our experts today to find the perfect muffle furnace for your specific application and ensure the integrity of your high-temperature processes.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why do we need sintering? To create strong, dense parts without melting.

- What is the function of an external heating high-temperature furnace in SCWG? Optimize Your Biomass Gasification Research

- Why is a high-temperature box resistance furnace necessary for mixed rare earth niobate synthesis? | KINTEK

- What function does a muffle furnace serve in Mg-doped NASICON powder preparation? Master Solid-State Synthesis

- What role do muffle or tube furnaces play in Ni-Mn-Sn-In alloy processing? Achieve Precise Material Transformation

- What role does a high-temperature furnace play in producing OMA? Master Precision Calcination for Pure Mesoporous Alumina

- What is the function of a high-temperature box-type resistance furnace? Optimize Stainless Steel Homogenization

- What is the purpose of using a high-temperature furnace to calcinate SiC? Optimize 2024Al/Gr/SiC Composite Performance