Bio-oil produced from pyrolysis is primarily used as a renewable substitute for industrial fuel oil in stationary applications like boilers, furnaces, and power plants. Beyond direct combustion for heat and power, it is also being developed as a feedstock for producing advanced transportation fuels and a wide range of bio-based chemicals and materials.

While bio-oil presents a promising renewable alternative to fossil fuels, its raw form is acidic, unstable, and has a low energy density. Therefore, its practical application is split between direct use as a low-grade industrial fuel and upgrading it into higher-value, more stable liquid fuels and chemical products.

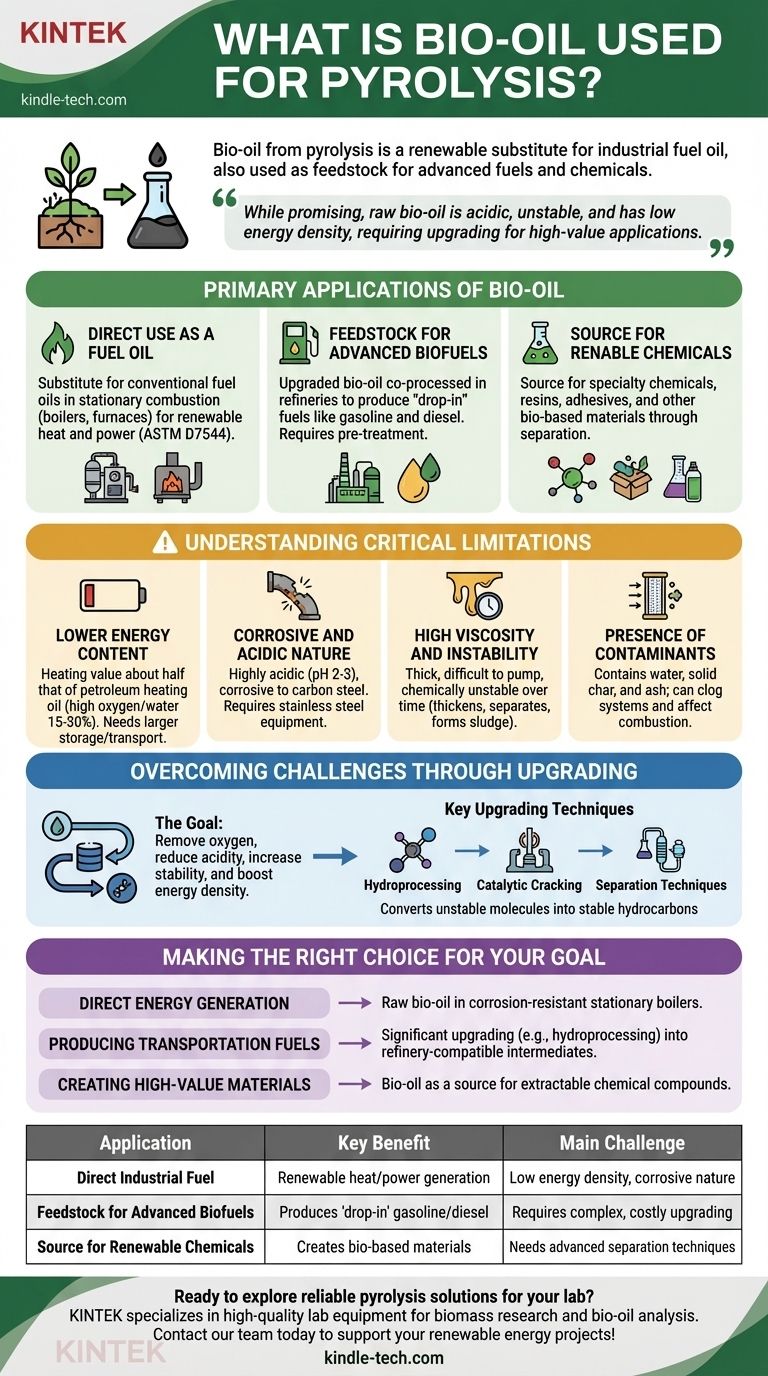

Primary Applications of Bio-Oil

Bio-oil, sometimes called pyrolysis oil, is a complex mixture of oxygenated organic compounds. Its uses are dictated by its unique and often challenging chemical properties.

Direct Use as a Fuel Oil

The most immediate application for bio-oil is as a direct substitute for conventional fuel oils in stationary combustion. This is regulated in some regions by standards like ASTM D7544.

This includes use in industrial boilers, furnaces, and even some diesel engines and turbines modified for this purpose. It is a way to generate renewable heat and power from waste biomass.

Feedstock for Advanced Biofuels

A more advanced application involves upgrading the raw bio-oil so it can be co-processed in existing petroleum refineries. This allows for the production of "drop-in" hydrocarbon fuels like gasoline and diesel.

This pathway requires significant pre-treatment to remove oxygen, reduce acidity, and improve stability, making the bio-oil compatible with traditional refinery infrastructure.

Source for Renewable Chemicals

Bio-oil is not a single substance but a collection of valuable chemical compounds. Through separation and refinement, it can serve as a source for producing specialty chemicals, resins, adhesives, and other bio-based materials.

This approach treats bio-oil not as a fuel to be burned, but as a "bio-refinery" feedstock, similar to how crude oil is used to produce both fuels and plastics.

Understanding the Critical Limitations

The widespread industrial use of raw bio-oil is limited by several significant technical challenges. Acknowledging these issues is critical to understanding its true potential.

Lower Energy Content

The heating value of bio-oil is only about half that of petroleum-based heating oil by weight. This is primarily due to its high oxygen and water content (15-30%).

This means you need roughly twice the volume of bio-oil to produce the same amount of energy, which has major implications for transport and storage logistics.

Corrosive and Acidic Nature

Bio-oil is highly acidic, with a pH typically between 2 and 3. This makes it extremely corrosive to common construction metals like carbon steel.

Using bio-oil requires storage tanks, pipes, and pumps made from stainless steel or other corrosion-resistant materials, increasing capital costs.

High Viscosity and Instability

Compared to conventional fuels, bio-oil can be thick and viscous, making it difficult to pump, especially at lower temperatures.

Furthermore, it is chemically unstable. Over time, it can undergo reactions that cause it to thicken, separate, and form sludge, creating storage and operational problems.

Presence of Contaminants

Raw bio-oil contains water, solid particulates (char), and ash from the original biomass. These contaminants can clog fuel lines and injectors and affect combustion efficiency.

Overcoming Challenges Through Upgrading

To overcome these limitations and unlock higher-value applications, raw bio-oil must be "upgraded" in a secondary process.

The Goal of Upgrading

Bio-oil upgrading refers to a set of chemical processes designed to improve its properties. The primary goals are to remove oxygen, reduce acidity, increase chemical stability, and boost its energy density.

Key Upgrading Techniques

Common methods include hydroprocessing (reacting the oil with hydrogen at high pressure), catalytic cracking, and separation techniques.

This converts the unstable, oxygenated compounds into stable hydrocarbons that more closely resemble conventional crude oil, making them suitable for use as transportation fuels or refinery-ready feedstocks.

Making the Right Choice for Your Goal

The best way to use bio-oil depends entirely on your technical capabilities and economic objective.

- If your primary focus is direct energy generation: Your path is using raw bio-oil in stationary boilers, but you must invest in corrosion-resistant equipment and a robust fuel handling system.

- If your primary focus is producing transportation fuels: You must plan for a significant upgrading process, like hydroprocessing, to convert the raw bio-oil into a stable, refinery-compatible intermediate.

- If your primary focus is creating high-value materials: Your strategy should be to view bio-oil as a source of extractable chemical compounds, requiring advanced separation and purification technologies.

Ultimately, the value of bio-oil is unlocked by choosing an application that respects its inherent chemical properties, whether through direct use in specialized equipment or advanced refinement into a more versatile product.

Summary Table:

| Application | Key Benefit | Main Challenge |

|---|---|---|

| Direct Industrial Fuel | Renewable heat/power generation | Low energy density, corrosive nature |

| Feedstock for Advanced Biofuels | Produces 'drop-in' gasoline/diesel | Requires complex, costly upgrading |

| Source for Renewable Chemicals | Creates bio-based materials | Needs advanced separation techniques |

Ready to explore reliable pyrolysis solutions for your lab? KINTEK specializes in high-quality lab equipment and consumables for biomass research and bio-oil analysis. Our experts can help you select the right tools to efficiently produce and characterize bio-oil, whether your goal is fuel testing or chemical extraction. Contact our team today to discuss how we can support your renewable energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electrolytic Electrochemical Cell for Coating Evaluation

- Rotating Platinum Disk Electrode for Electrochemical Applications

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- Can you heat treat cast aluminum? Strengthening Specific Alloys for Demanding Applications

- How long does pyrolysis take? From Seconds to Days for Bio-Oil or Biochar

- What is the role of a high-pressure homogenizer in PHA extraction? Optimize Your Bio-Material Recovery Process

- What are the benefits of converting plastic waste into fuel? Turning Waste into a Valuable Energy Resource

- What is a pusher furnace? A Guide to Continuous High-Volume Thermal Processing

- What are the critical functions of high-purity nitrogen during the biomass pyrolysis process? Enhance Product Integrity

- What is the bias of sputtering RF? How a Negative DC Self-Bias Enables Insulator Sputtering

- What are the 5 heat treatment processes? Master Annealing, Hardening, Tempering & More