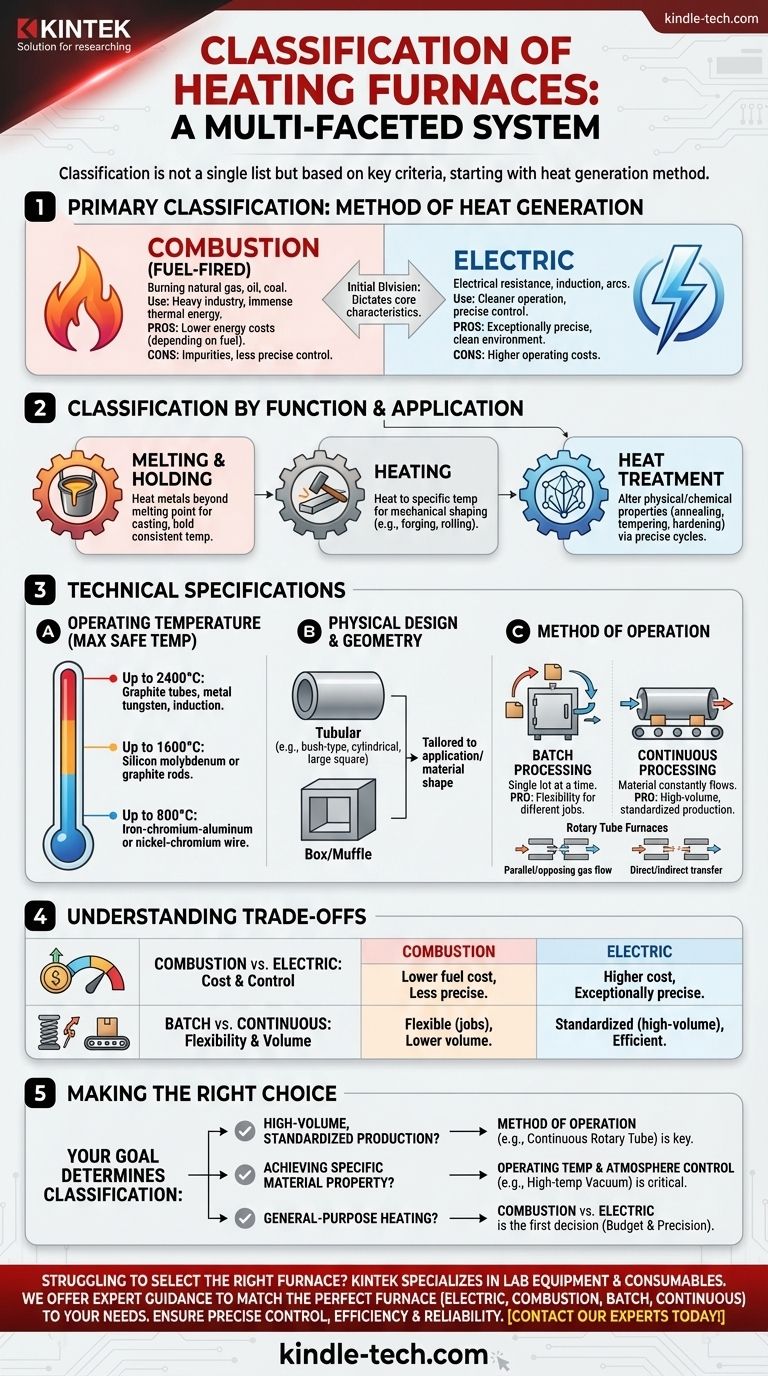

The classification of heating furnaces is not a single list but a multi-faceted system based on several key criteria. At the most fundamental level, furnaces are classified by their method of heat generation: either through the combustion of fuel or through the use of electricity.

While the initial distinction is between fuel-fired and electric types, a true understanding comes from recognizing that furnaces are further classified by their function, operating temperature, physical design, and method of operation to match specific industrial processes.

The Primary Classification: Method of Heat Generation

The most common way to categorize furnaces is by their primary energy source. This initial division dictates many of the furnace's core characteristics, from cost to precision.

Combustion Furnaces (Fuel-Fired)

Combustion furnaces generate heat by burning fuels such as natural gas, oil, or coal. They are widely used in heavy industry for applications requiring immense thermal energy.

Electric Furnaces

Electric furnaces use electrical energy to generate heat. This is typically achieved through methods like electrical resistance, induction, or electric arcs, offering cleaner operation and more precise temperature control.

Classification by Function and Application

Beyond the heat source, furnaces are defined by what they are designed to do. This functional classification aligns the equipment with a specific industrial goal.

Melting and Holding Furnaces

These furnaces are designed to heat metals beyond their melting point for casting. They must also be able to hold the molten metal at a consistent temperature.

Heating Furnaces

The purpose of these furnaces is to heat materials to a specific temperature for mechanical shaping. This includes processes like forging or rolling, where the material must be softened but not melted.

Heat Treatment Furnaces

These furnaces are used to alter the physical and chemical properties of a material. Processes like annealing, tempering, and hardening require precise temperature cycles to achieve the desired microstructure.

Classification by Technical Specifications

For engineering and process-specific applications, furnaces are classified by their technical and design characteristics. These details determine a furnace's suitability for highly specialized tasks.

Operating Temperature

A critical classification is the furnace's maximum safe operating temperature. This is determined by the materials used for its heating elements and insulation.

For example, vacuum furnaces are often categorized this way:

- Up to 800°C: Use iron-chromium-aluminum or nickel-chromium wire heating elements.

- Up to 1600°C: Require more robust elements like silicon molybdenum rods or graphite rods.

- Up to 2400°C: Rely on advanced methods like graphite tubes, metal tungsten, or induction heating.

Physical Design and Geometry

The shape and structure of a furnace are tailored to its application. Tubular furnaces, for instance, can be classified as bush-type, cylindrical, or large square designs depending on the material being processed.

Method of Operation

This classification describes how the material moves through the furnace and how heat is transferred.

Rotary tube furnaces, designed for continuous processing, are classified by their method of heat exchange (parallel or opposing gas flow) and energy transfer (direct, indirect, or combined). This determines the efficiency and uniformity of heating for materials that flow through the unit.

Understanding the Trade-offs

Choosing or specifying a furnace requires understanding the inherent trade-offs between different classifications. No single type is universally superior; the best choice is always context-dependent.

Combustion vs. Electric: Cost and Control

Combustion furnaces often have lower energy costs where fuel is inexpensive, but they can introduce impurities from the fuel and offer less precise temperature control. Electric furnaces are more expensive to operate but provide exceptionally precise control and a cleaner processing environment, which is critical for sensitive materials.

Batch vs. Continuous: Flexibility and Volume

Furnaces can be designed for batch processing (loading a single lot at a time) or continuous processing (material constantly flows through). Batch furnaces offer flexibility for different jobs, while continuous furnaces, like rotary tube models, are built for high-volume, standardized production where efficiency is paramount.

Making the Right Choice for Your Goal

Your primary objective determines which classification is most important for your decision.

- If your primary focus is high-volume, standardized production: The method of operation (e.g., a continuous rotary tube furnace) is the most relevant classification.

- If your primary focus is achieving a specific material property: Classification by operating temperature and atmosphere control (e.g., a high-temperature vacuum furnace) is critical.

- If your primary focus is general-purpose heating: The fundamental classification of combustion vs. electric will be your first decision, based on your budget and precision needs.

Ultimately, understanding furnace classification is about matching the right tool to your specific engineering or manufacturing challenge.

Summary Table:

| Classification Criteria | Key Types | Primary Use Case |

|---|---|---|

| Heat Generation | Combustion, Electric | Heavy industry vs. precision heating |

| Function | Melting, Heating, Heat Treatment | Casting, forging, material property alteration |

| Operating Temperature | Up to 800°C, 1600°C, 2400°C | Matched to material melting points and treatment specs |

| Operation Method | Batch, Continuous | Flexible production vs. high-volume processing |

Struggling to select the right furnace for your lab or production line? KINTEK specializes in lab equipment and consumables, offering expert guidance to match the perfect furnace—whether electric, combustion, batch, or continuous—to your specific needs. Ensure precise temperature control, efficiency, and process reliability. Contact our experts today for a tailored solution!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of a tube furnace? Achieve Superior Thermal Control and Purity

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What temperature is alumina activated? Unlock Optimal Porosity for Adsorption

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere