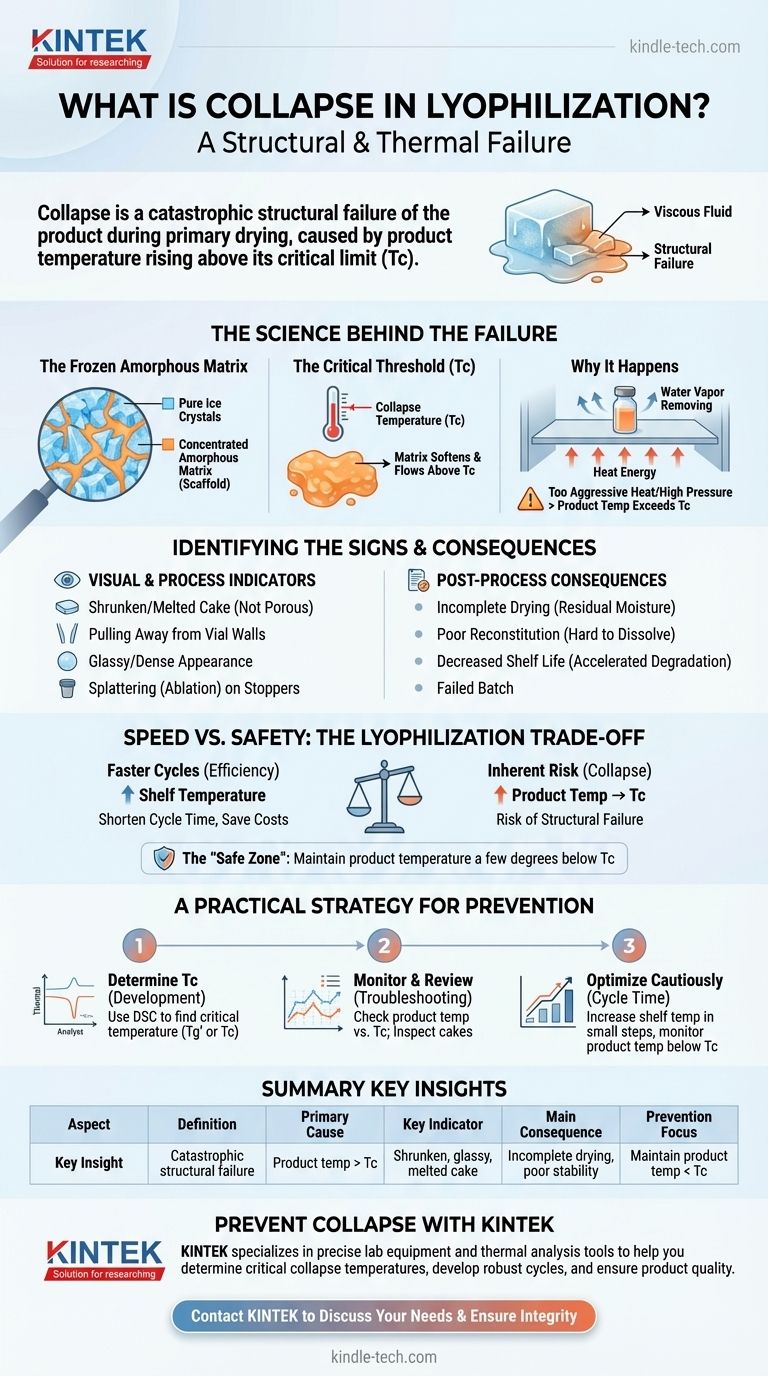

In lyophilization, collapse is a catastrophic structural failure of the product during the primary drying phase. It occurs when the frozen product matrix softens to a viscous fluid, losing its ability to support its own structure as ice is removed, which leads to a shrunken or melted appearance, incomplete drying, and poor final product quality.

Collapse is fundamentally a temperature control failure. It happens when your product's temperature rises above its specific critical limit—its collapse temperature (Tc)—causing the solid scaffold to weaken and give way, irreversibly compromising the entire batch.

The Science Behind Structural Failure

To prevent collapse, you must first understand the microscopic structure of your frozen product and the thermal forces at play during drying.

The Frozen Amorphous Matrix

During freezing, most of the water in your product forms pure ice crystals. Everything else—your active ingredient and any excipients—becomes concentrated into unfrozen, glassy regions between these ice crystals. This is the amorphous matrix, and it acts as the solid scaffold that gives the final dried cake its shape and porosity.

The Critical Threshold: Collapse Temperature (Tc)

This amorphous scaffold is not infinitely stable. It has a specific temperature, the collapse temperature (Tc), above which it loses its rigidity and begins to flow like a highly viscous liquid. This temperature is a unique physical property of your specific product formulation.

Why It Happens During Drying

Primary drying (sublimation) is a delicate balance. The vacuum chamber pulls water vapor from the ice crystals, a process which inherently cools the product. Simultaneously, the freeze dryer's shelves provide heat energy to fuel this sublimation.

If the heat input is too aggressive, or the chamber pressure is too high, the product's temperature at the sublimation front can rise and exceed its collapse temperature. At this point, the structural scaffold weakens and can no longer resist the forces of the escaping water vapor, leading to structural failure.

Identifying the Signs of Collapse

Collapse is not always a complete, uniform meltdown. It can be subtle, but the consequences are always significant.

Visual Appearance of the Cake

The most obvious sign is the appearance of the dried product, or "cake." Instead of a uniform, porous structure, a collapsed cake may show signs of shrinkage, pulling away from the vial walls. It may also have a glassy, melted, or dense appearance in parts or throughout the entire cake.

Process Indicators

During the cycle itself, you may observe splattering of the product onto the vial stoppers or walls, a phenomenon known as ablation. This happens when pockets of trapped water vapor escape violently from the softened matrix.

Post-Process Consequences

A collapsed product is a failed product. It suffers from several critical defects:

- Incomplete Drying: The dense, non-porous structure traps residual moisture, which cannot be removed in subsequent drying phases.

- Poor Reconstitution: The final product will be difficult or impossible to dissolve, defeating its purpose.

- Decreased Shelf Life: High residual moisture dramatically accelerates degradation and reduces the long-term stability of the product.

Understanding the Trade-offs: Speed vs. Safety

Every lyophilization cycle is a negotiation between process efficiency and product quality. The risk of collapse lies at the heart of this negotiation.

The Drive for Faster Cycles

The goal of process optimization is often to shorten the lengthy lyophilization cycle. The most direct way to do this is to increase the shelf temperature, which accelerates the rate of sublimation. This saves time, energy, and money.

The Inherent Risk

Pushing the shelf temperature higher brings the product's temperature closer to its collapse temperature (Tc). Without precise control and a deep understanding of your product's thermal properties, you can easily cross this threshold by accident. An aggressive cycle designed for speed can quickly become a failed batch.

The "Safe Zone" of Operation

The core principle of robust lyophilization is to maintain a "safe zone" by ensuring the product temperature always stays a few degrees below its determined collapse temperature. This safety margin accounts for slight variations across the shelf and between different vials.

A Practical Strategy for Your Process

Preventing collapse requires a proactive, data-driven approach to process development and control.

- If your primary focus is process development: You must first determine your product's critical temperature (often using the glass transition temperature, Tg', as a close proxy for Tc) through thermal analysis like Differential Scanning Calorimetry (DSC).

- If your primary focus is troubleshooting a failed batch: Review process data to see if the product temperature exceeded its known Tc, and visually inspect the cakes for the classic signs of shrinkage and a glassy, non-uniform structure.

- If your primary focus is optimizing cycle time: Cautiously increase the shelf temperature in small, controlled steps while directly monitoring product temperature to ensure it remains safely below the collapse threshold.

Mastering the relationship between your product's formulation and its critical temperature is the key to developing robust and efficient lyophilization cycles.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Definition | Catastrophic structural failure during primary drying. |

| Primary Cause | Product temperature exceeds the collapse temperature (Tc). |

| Key Indicator | Shrunken, glassy, or melted appearance of the dried cake. |

| Main Consequence | Incomplete drying, poor reconstitution, and reduced shelf life. |

| Prevention Focus | Maintain product temperature safely below Tc during drying. |

Prevent Lyophilization Collapse and Optimize Your Process with KINTEK

Collapse is a critical failure that can compromise your entire batch. KINTEK specializes in providing the precise lab equipment and consumables you need to master your lyophilization process. From thermal analysis tools to determine your product's critical collapse temperature to reliable freeze-drying systems, we help you ensure product quality and maximize efficiency.

Our experts understand the delicate balance between speed and safety in freeze-drying. Let us help you develop robust, data-driven cycles that prevent structural failure.

Contact KINTEK today to discuss your laboratory's specific needs and ensure the integrity of your lyophilized products.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the main pharmaceutical applications of lab freeze dryers? Stabilize Drugs from R&D to Manufacturing

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- What are the key advantages of using freeze dryers? Achieve Unmatched Preservation for Your Materials

- What is the primary technique used by lab freeze dryers to process materials? Lyophilization for Superior Sample Preservation

- What are the hazards of evaporators? Manage Chemical, Thermal, and Pressure Risks