In short, CVD products are high-purity, high-performance materials created through a process called Chemical Vapor Deposition. Rather than a single item, "CVD" describes a class of materials—from ultra-hard industrial coatings to flawless lab-grown diamonds—that are built atom-by-atom from a chemical gas onto a substrate in a controlled environment.

The core concept to understand is that CVD is not a product itself, but a sophisticated manufacturing process. It excels at creating materials that are exceptionally dense, pure, and uniform, making them harder and more durable than their conventionally produced counterparts.

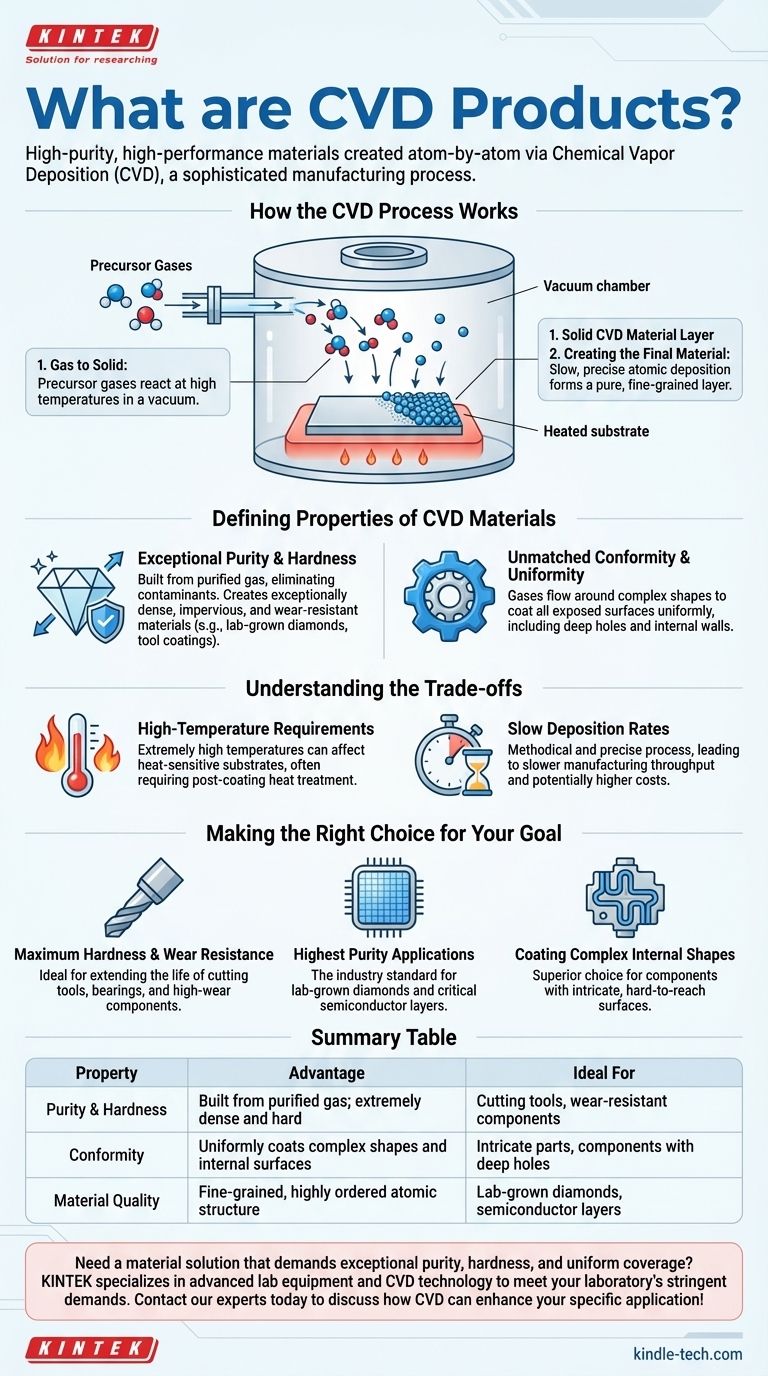

How the CVD Process Works

Chemical Vapor Deposition is a method for creating a solid material, typically a thin film or coating, by depositing atoms from a gaseous state onto a solid surface.

The Basic Principle: Gas to Solid

The process takes place inside a vacuum chamber containing the object to be coated, known as the substrate.

This substrate is heated to very high temperatures, and one or more precursor gases are introduced. The intense heat causes these gases to react and decompose, releasing the desired atoms which then bond to the hot substrate, building up a solid layer.

Creating the Final Material

This deposition happens slowly and with incredible precision, often at a rate of just a few microns per minute.

The result is a new material layer that is built from the ground up, ensuring a very pure and highly ordered, fine-grained structure. This atomic-level control is what gives CVD products their unique characteristics.

Defining Properties of CVD Materials

Materials created via CVD are valued for a specific set of superior properties that are difficult to achieve through other manufacturing methods.

Exceptional Purity and Hardness

Because the material is built directly from a purified gas, it avoids the contaminants and structural imperfections common in materials that are cast or sintered.

This high purity and fine-grained structure result in materials that are incredibly dense, impervious, and hard—often significantly harder than the same material made by conventional means.

Unmatched Conformity and Uniformity

A key advantage of CVD is its ability to coat complex shapes evenly. The precursor gas flows around the entire substrate, reaching into deep holes, internal walls, and intricate geometries.

This creates a perfectly uniform coating across all exposed surfaces, something that line-of-sight processes like physical vapor deposition (PVD) cannot easily do.

Understanding the Trade-offs

While powerful, the CVD process has specific requirements and limitations that make it suitable for some applications but not others.

High-Temperature Requirements

CVD operates at extremely high temperatures. This can be a problem for heat-sensitive substrates.

For example, when coating steel tools, the process temperature often exceeds the steel's tempering point. This means the tool must be put through a separate vacuum heat treatment after coating to restore its necessary hardness.

Slow Deposition Rates

The process is methodical and precise, which means it is also relatively slow. This can impact manufacturing throughput and cost compared to faster, less precise methods.

Support Points and Surface Finish

The areas where a substrate is physically held or supported within the chamber will not be coated. Additionally, the resulting CVD coating can have a slightly rougher surface finish than the original substrate.

Making the Right Choice for Your Goal

Understanding when to leverage CVD comes down to matching its unique benefits to your primary objective.

- If your primary focus is maximum hardness and wear resistance: CVD coatings provide an exceptionally durable layer for extending the life of cutting tools, bearings, and other high-wear components.

- If your primary focus is creating materials of the highest purity: The CVD process is the industry standard for applications like lab-grown diamonds and manufacturing critical semiconductor layers.

- If your primary focus is coating complex internal shapes uniformly: CVD's ability to deposit material from a gas makes it the superior choice for components with intricate or hard-to-reach surfaces.

Ultimately, CVD products represent a class of materials engineered at the atomic level for superior performance where purity and durability are non-negotiable.

Summary Table:

| Property | Advantage | Ideal For |

|---|---|---|

| Purity & Hardness | Built from purified gas; extremely dense and hard | Cutting tools, wear-resistant components |

| Conformity | Uniformly coats complex shapes and internal surfaces | Intricate parts, components with deep holes |

| Material Quality | Fine-grained, highly ordered atomic structure | Lab-grown diamonds, semiconductor layers |

Need a material solution that demands exceptional purity, hardness, and uniform coverage?

KINTEK specializes in advanced lab equipment and consumables, including CVD technology, to meet the stringent demands of your laboratory. Whether you are developing next-generation semiconductors, creating durable tool coatings, or growing high-purity crystals, our expertise can help you achieve superior results.

Contact our experts today to discuss how CVD can enhance your specific application!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications