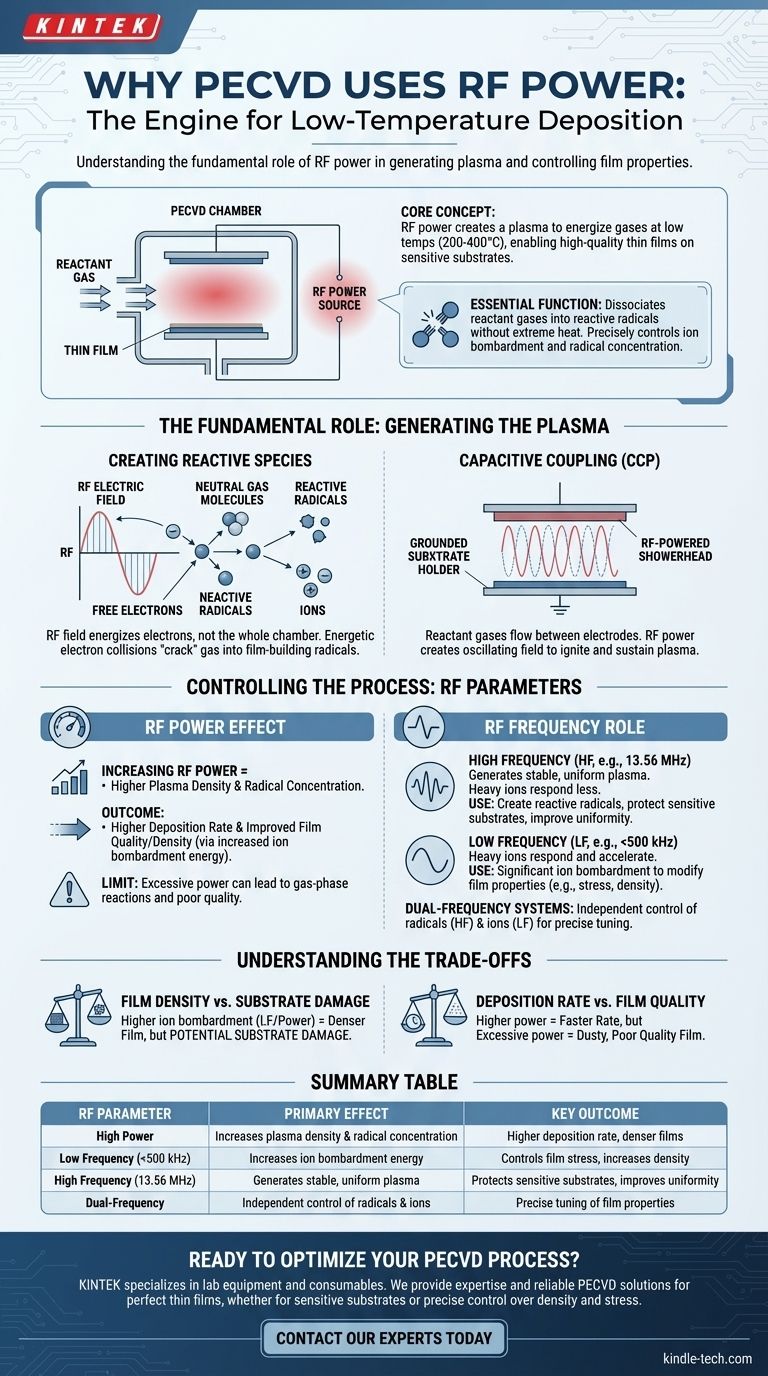

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses a Radio Frequency (RF) power source to create a plasma. This plasma energizes reactant gases at much lower temperatures than traditional thermal CVD, allowing for the deposition of high-quality thin films on substrates that cannot withstand high heat. The RF power is the engine that drives the entire low-temperature deposition process.

The essential function of RF power in PECVD is to dissociate reactant gases into chemically reactive species (radicals) without extreme heat. By carefully controlling the RF power and frequency, engineers can precisely manipulate ion bombardment and radical concentration, thereby dictating the final film's properties, such as density, stress, and deposition rate.

The Fundamental Role of RF: Generating the Plasma

PECVD's primary advantage over other methods is its ability to operate at low temperatures (typically 200-400°C). This is made possible entirely by the use of RF energy to generate a plasma.

Creating Reactive Species Without Heat

In a PECVD chamber, an RF electric field is applied across the reactant gases. This field doesn't heat the entire chamber; instead, it energizes the free electrons within the gas.

These high-energy electrons collide with the neutral gas molecules. The collisions are energetic enough to break chemical bonds and "crack" the gas molecules apart, creating highly reactive radicals and ions.

These radicals are the building blocks of the thin film. Because they are so chemically reactive, they readily form a stable film on the substrate surface without requiring high thermal energy.

How Capacitive Coupling Works

The most common method for applying this energy is through a capacitively coupled plasma (CCP) system.

Reactant gases flow between two parallel electrodes. One electrode, often the substrate holder, is grounded, while the other (a "showerhead" that introduces the gas) is connected to the RF power source.

The RF power creates an oscillating electric field between the electrodes, which ignites and sustains the plasma.

Controlling the Process: The Impact of RF Parameters

The true power of PECVD lies in the fine control offered by adjusting the RF source. The two main levers are power and frequency, which have distinct effects on the process.

The Effect of RF Power

Increasing the RF power directly increases the density of the plasma and the concentration of free radicals.

This generally leads to a higher deposition rate, as more film-forming radicals are available to deposit on the substrate. However, this effect has a limit. Once the reactant gas is fully dissociated, adding more power will not increase the rate further.

Higher power also increases the bombardment energy of ions hitting the substrate, which can compact the growing film and improve its quality and density.

The Critical Role of RF Frequency

The frequency of the RF source is a more subtle but critical parameter. Systems often use a combination of high and low frequencies to achieve specific film properties.

High Frequency (HF), typically the industrial standard 13.56 MHz, is excellent for generating a dense, stable plasma. At this frequency, the heavy ions cannot respond to the rapidly changing electric field, so they contribute less to bombarding the substrate. HF power is therefore used primarily to create the reactive radicals needed for deposition.

Low Frequency (LF), typically below 500 kHz, has a different effect. The electric field oscillates slowly enough that the heavier ions can respond and accelerate toward the substrate. This results in significant, high-energy ion bombardment, which is used to modify film properties like compressive stress and increase film density.

Understanding the Trade-offs

Manipulating RF parameters always involves balancing competing factors. Understanding these trade-offs is key to process optimization.

Film Density vs. Substrate Damage

Increasing ion bombardment—either by adding LF power or increasing total power—creates a denser, more compact film.

The trade-off is potential substrate damage. High-energy ion bombardment can physically damage sensitive substrates or introduce defects into the film itself.

Deposition Rate vs. Film Quality

While higher power increases the deposition rate, excessively high power can lead to gas-phase reactions, creating particles that result in a dusty, poor-quality film.

There is always an optimal power window that balances a practical deposition rate with the desired film quality.

Uniformity Considerations

Higher frequencies (like 13.56 MHz) generally produce a more uniform plasma across the entire substrate.

At lower frequencies, the electric field can be weaker near the edges of the electrodes, leading to lower deposition rates at the wafer's edge and causing non-uniform film thickness.

Applying This to Your Deposition Goals

Your choice of RF parameters should be dictated by the desired outcome for your film.

- If your primary focus is a high deposition rate: Increase the primary RF power, but stay below the threshold where film quality degrades or the rate saturates.

- If your primary focus is high film density or stress control: Use a dual-frequency system, applying LF power to independently control ion bombardment energy and compact the film.

- If your primary focus is protecting a sensitive substrate: Rely mainly on HF power to generate the plasma while minimizing or eliminating LF power to reduce damaging ion bombardment.

- If your primary focus is film uniformity across a large area: Prioritize the use of a high-frequency source (13.56 MHz or higher) to ensure a more evenly distributed plasma.

Ultimately, the RF power source is the central control knob for tuning the properties of your deposited film in a PECVD system.

Summary Table:

| RF Parameter | Primary Effect on PECVD Process | Key Outcome |

|---|---|---|

| High Power | Increases plasma density & radical concentration | Higher deposition rate, denser films |

| Low Frequency (<500 kHz) | Increases ion bombardment energy | Controls film stress, increases density |

| High Frequency (13.56 MHz) | Generates stable, uniform plasma | Protects sensitive substrates, improves uniformity |

| Dual-Frequency | Independent control of radicals & ions | Precise tuning of film properties |

Ready to Optimize Your PECVD Process?

Understanding RF power is just the first step. KINTEK specializes in lab equipment and consumables, providing the expertise and reliable PECVD solutions you need to achieve perfect thin films for your specific application—whether you're working with sensitive substrates or require precise control over density and stress.

Contact our experts today to discuss how we can help you enhance your deposition results and accelerate your research or production.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition