At its core, heat treatment is a highly controlled process of heating and cooling a metal part to deliberately change its internal structure. For small parts, this isn't a brute-force method; it's a precise, metallurgical technique used to unlock specific mechanical properties that the base metal doesn't possess on its own, such as extreme hardness or enhanced durability.

The fundamental purpose of heat treating small parts is not simply to make them hot, but to use temperature as a tool to fundamentally re-engineer the material at a microscopic level, achieving a specific outcome like superior strength or wear resistance.

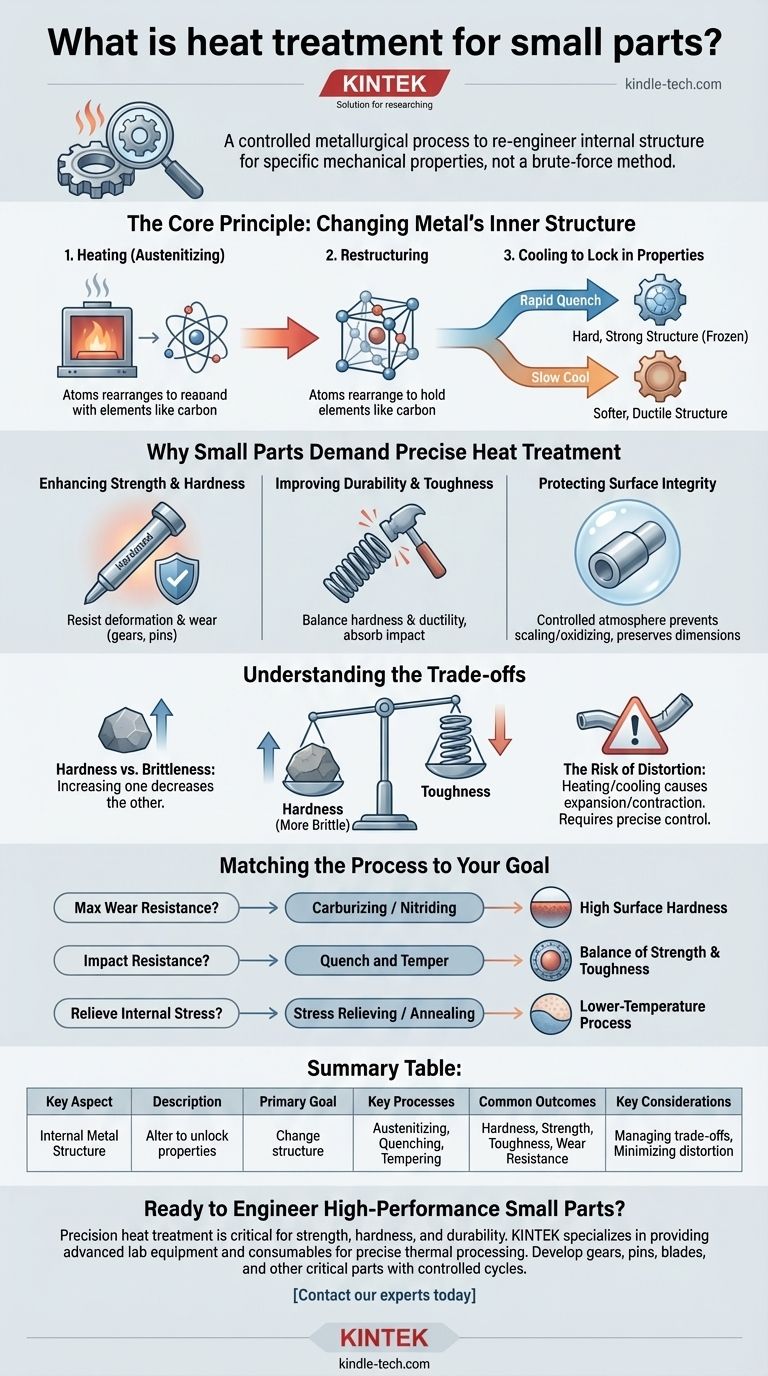

The Core Principle: Changing Metal's Inner Structure

Heat treatment works by manipulating the crystalline structure of a metal. Think of it as a form of "physical programming" for the material itself.

The Goal of Controlled Change

The entire process is intentional. Engineers select a specific heating temperature, duration, and cooling method to produce a predictable and repeatable outcome. The goal is to alter properties to meet the demands of a specific application.

Heating to Restructure

When a metal part is heated to a critical temperature (a process known as austenitizing), its atoms rearrange into a different crystal structure. This new structure can hold other elements, like carbon, in a way the original structure could not.

Cooling to Lock in Properties

The speed at which the part is cooled determines the final result. A rapid quench "freezes" a hard, strong structure in place, while a slower cool allows for a softer, more ductile structure to form.

Why Small Parts Demand Precise Heat Treatment

While the principles are the same for all parts, the stakes are higher for small, often complex components. The precision of the heat treatment process directly impacts their performance and reliability.

Enhancing Strength and Hardness

The most common reason to heat treat a small part is to increase its hardness and strength. This allows a small gear, pin, or blade to resist deformation and wear far better than it could in its untreated state.

Improving Durability and Toughness

While hardness is crucial, some parts also need toughness—the ability to absorb impact without fracturing. Different heat treatment cycles can be designed to create a balance between hardness on the surface and a more ductile, tough core.

Protecting Surface Integrity

For small, high-precision parts, the surface finish is critical. During heating, a controlled atmosphere is often used in the furnace. This specialized gas environment protects the part from scaling or oxidizing, preserving its dimensions and surface quality.

Understanding the Trade-offs

Heat treatment is a powerful tool, but it involves balancing competing properties. Understanding these compromises is essential for making sound engineering decisions.

Hardness vs. Brittleness

The most fundamental trade-off is between hardness and brittleness. As you increase a metal's hardness, you almost always decrease its toughness, making it more susceptible to shattering under sudden impact.

The Risk of Distortion

Heating and cooling metal inevitably causes it to expand and contract. For small parts with tight tolerances, this can lead to warping or distortion if the process is not managed with extreme care. Fixturing and precise temperature control are critical to minimize this risk.

Matching the Process to Your Goal

The right heat treatment method is always dictated by the part's intended function.

- If your primary focus is maximum wear resistance: A process designed for high surface hardness, like carburizing or nitriding, is the optimal choice.

- If your primary focus is impact resistance: A quench and temper process is used to achieve a good balance of strength and toughness through the entire part.

- If your primary focus is relieving internal stress from manufacturing: A lower-temperature process like stress relieving or annealing is the correct path.

Ultimately, heat treatment transforms a simple metal component into a high-performance part engineered for a specific task.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Alter internal metal structure to unlock specific mechanical properties. |

| Key Processes | Austenitizing (heating), Quenching (rapid cooling), Tempering. |

| Common Outcomes | Increased hardness, enhanced strength, improved toughness, wear resistance. |

| Key Considerations | Managing trade-offs (e.g., hardness vs. brittleness), minimizing distortion. |

Ready to Engineer High-Performance Small Parts?

Precision heat treatment is critical for unlocking the full potential of your small components, ensuring they meet the demanding requirements of strength, hardness, and durability. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise thermal processing.

Whether you are developing gears, pins, blades, or other critical small parts, our solutions support the controlled heating and cooling cycles essential for repeatable, high-quality results.

Contact our experts today to discuss how KINTEK can support your laboratory's specific heat treatment challenges and help you achieve superior material performance.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control