At its core, microwave sintering is a highly efficient method for heating and bonding powdered materials into a solid, dense form. Unlike conventional ovens that heat from the outside in, this process uses microwave energy to heat the material directly and uniformly from within. This "volumetric heating" leads to significantly faster processing times, lower energy consumption, and can produce materials with superior properties.

Microwave sintering revolutionizes traditional material processing by using electromagnetic waves to heat materials internally. This approach results in significantly faster, more uniform, and energy-efficient densification compared to the slow, external heating of conventional furnaces.

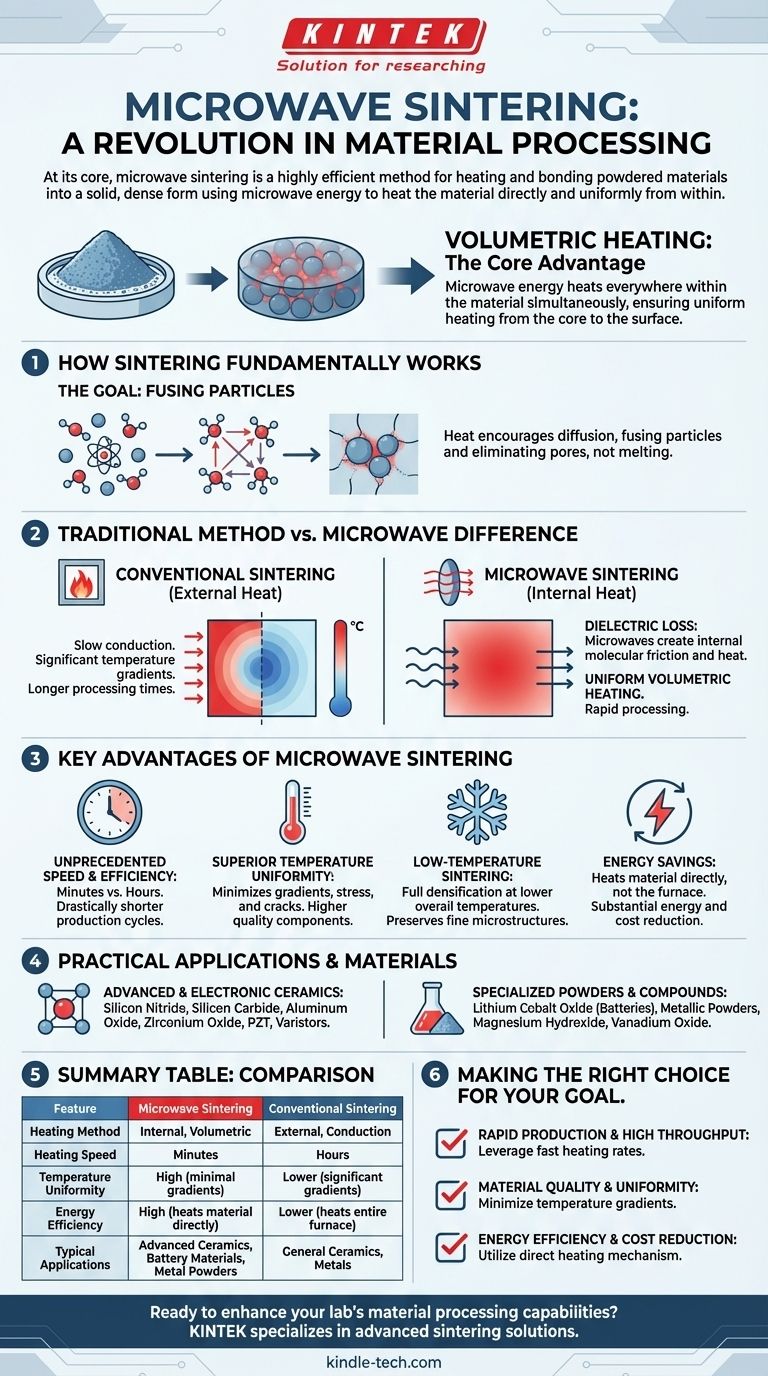

How Sintering Fundamentally Works

The Goal: Fusing Particles

Sintering is the process of taking a compacted powder and turning it into a solid, dense object using heat. The goal is not to melt the material completely.

Instead, the heat encourages atoms to move, or diffuse, across the boundaries of individual particles. This diffusion fuses the particles together, eliminating the pores between them and creating a single, solid piece.

The Traditional Method: External Heat

Conventional sintering takes place in a high-temperature furnace. The furnace heats the outside of the material first, and that heat slowly conducts its way to the center.

This process is often slow and can create significant temperature gradients, where the outside of the object is much hotter than the inside.

The Microwave Difference: Heating from Within

The Principle of Dielectric Loss

Microwave sintering works on a different principle. It uses the interaction between an electromagnetic field (the microwaves) and the material itself to generate heat.

This process, known as dielectric loss, causes the molecules within the material to vibrate rapidly, creating friction and generating heat instantly and internally.

The Advantage of Volumetric Heating

Because the heat is generated everywhere within the material simultaneously, it is known as volumetric heating. This is the fundamental advantage of the microwave method.

It eliminates the slow process of thermal conduction and ensures the entire object heats up at nearly the same rate, from the core to the surface.

Key Advantages of Microwave Sintering

Unprecedented Speed and Efficiency

The most significant benefit is speed. By heating the material directly, microwave sintering can achieve target temperatures in minutes rather than the hours required by conventional furnaces. This drastically shortens the entire production cycle.

Superior Temperature Uniformity

Volumetric heating minimizes the internal temperature gradients that can cause stress, cracks, or inconsistent density in the final product. This uniformity leads to higher-quality, more reliable components.

The Ability for Low-Temperature Sintering

Because the energy is delivered so efficiently, it's often possible to achieve full densification at a lower overall temperature than in a conventional furnace. This can help preserve fine-grained microstructures in the material, which is critical for certain high-performance applications.

Energy Savings

Heating only the material and not the massive volume of a furnace chamber is inherently more energy-efficient. This direct energy transfer results in substantial energy and cost savings, especially in industrial-scale production.

Practical Applications and Materials

Advanced and Electronic Ceramics

Microwave sintering is exceptionally well-suited for processing a wide range of advanced ceramics where high purity and precise properties are required.

Common materials include silicon nitride, silicon carbide, aluminum oxide, and zirconium oxide. It is also used for electronic devices like PZT piezoelectric ceramics and varistors.

Specialized Powders and Compounds

The technology is not limited to ceramics. It is also effective for sintering specialized materials such as lithium cobalt oxide (for batteries), various metallic powders, and other compounds like magnesium hydroxide and vanadium oxide.

Making the Right Choice for Your Goal

When evaluating this technology, consider what problem you are trying to solve.

- If your primary focus is rapid production and high throughput: Microwave sintering's fast heating rates offer a significant advantage over the slow cycle times of conventional furnaces.

- If your primary focus is material quality and uniformity: The internal, volumetric heating minimizes temperature gradients, leading to more consistent and reliable final products.

- If your primary focus is energy efficiency and cost reduction: This method's direct heating mechanism drastically cuts down on wasted energy and overall processing time.

Understanding this principle of internal heating is the key to leveraging microwave technology for advanced material manufacturing.

Summary Table:

| Feature | Microwave Sintering | Conventional Sintering |

|---|---|---|

| Heating Method | Internal, Volumetric | External, Conduction |

| Heating Speed | Minutes | Hours |

| Temperature Uniformity | High (minimal gradients) | Lower (significant gradients) |

| Energy Efficiency | High (heats material directly) | Lower (heats entire furnace) |

| Typical Applications | Advanced Ceramics, Battery Materials, Metal Powders | General Ceramics, Metals |

Ready to enhance your lab's material processing capabilities? KINTEK specializes in advanced lab equipment, including sintering solutions. Our expertise can help you achieve faster cycle times, superior product quality, and significant energy savings. Contact our experts today to discuss how microwave sintering can benefit your specific application!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are high-precision vacuum sintering furnaces preferred over traditional methods for biofunctional dental ceramics?

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency

- What is the advantage of firing porcelain in a vacuum? Achieve Denser, Stronger, and More Aesthetic Dental Restorations

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API