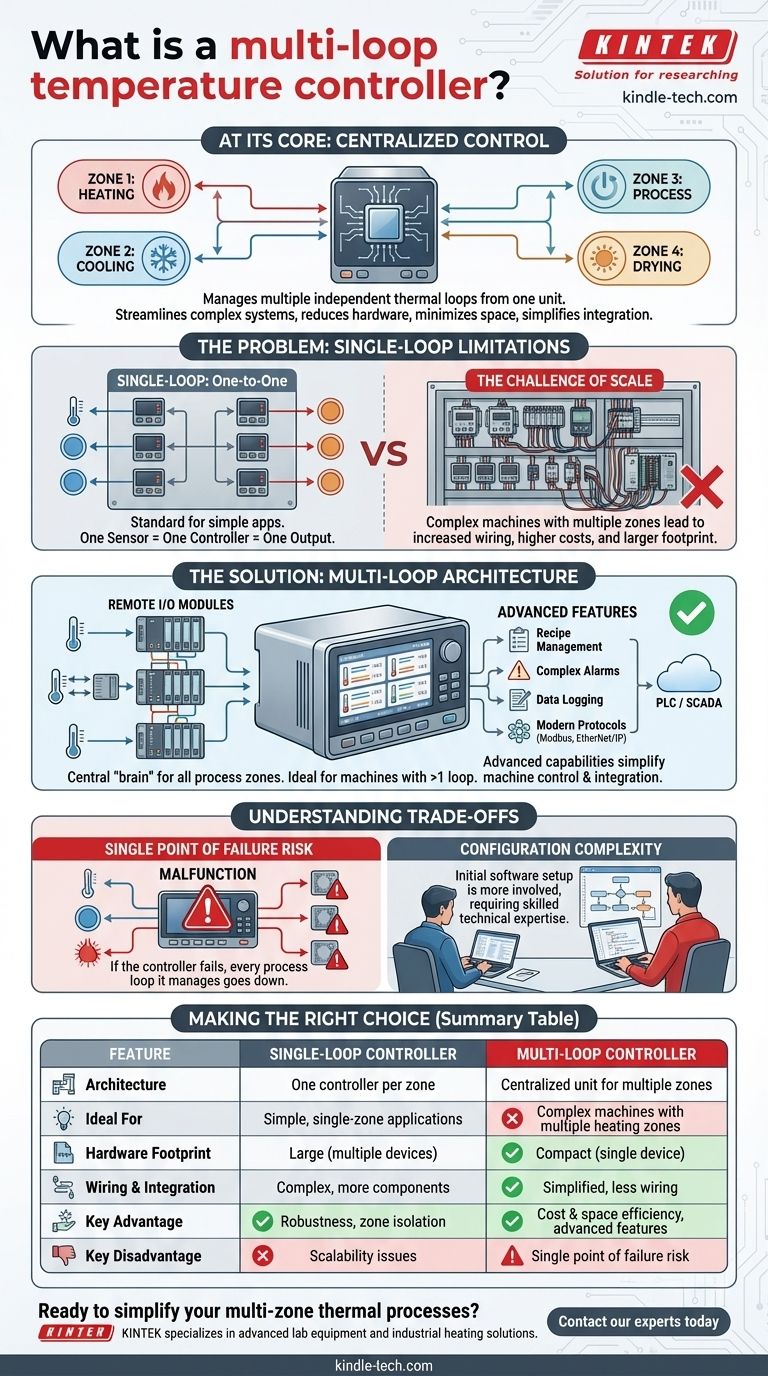

At its core, a multi-loop temperature controller is a centralized industrial device engineered to manage and regulate multiple independent thermal or process loops from a single, integrated unit. This allows it to simultaneously control different zones within a machine or process, a task that would otherwise require a separate controller for each individual loop.

The fundamental value of a multi-loop controller is its ability to streamline complex systems. By consolidating the control of multiple independent zones into one device, it reduces hardware complexity, minimizes panel space, and simplifies overall system integration and management.

The Problem: When Single-Loop Control Isn't Enough

To understand the purpose of a multi-loop controller, it's essential to first recognize the limitations of the traditional, single-loop approach.

The One-to-One Limitation

A standard single-loop controller operates on a simple principle: one sensor input, one controller, and one control output. This is a perfectly robust and effective solution for simple applications.

However, many industrial machines, such as packaging lines or plastics extruders, have multiple distinct heating zones that must be controlled independently but as part of a single, coordinated process.

The Challenge of Scale

Using single-loop controllers for these complex machines creates significant challenges. The result is often a large control panel filled with numerous individual devices, leading to increased wiring complexity, higher hardware costs, and a much larger physical footprint.

How Multi-Loop Controllers Provide a Solution

A multi-loop controller directly addresses the challenges of scale and complexity by fundamentally changing the control architecture.

A Centralized Architecture

Instead of a distributed array of individual controllers, a multi-loop system uses a single "brain" to manage all the process zones. This central unit receives inputs from multiple sensors and manages multiple control outputs, all within one compact housing.

This architecture is ideal for systems that require more than one control loop operating within a single machine.

Advanced Features and Integration

Modern multi-loop controllers are more than just a collection of single loops in a box. They often include advanced features that simplify machine control and integration.

These capabilities frequently include recipe management, complex alarm strategies, data logging, and modern communication protocols (like Modbus or EtherNet/IP) that allow for seamless connection to a central PLC or SCADA system.

Understanding the Trade-offs

While powerful, multi-loop controllers are not the universal solution. An objective evaluation requires acknowledging their potential downsides.

Single Point of Failure

The most significant trade-off is the risk of a centralized failure. If the multi-loop controller malfunctions, every process loop it manages will go down simultaneously. In contrast, the failure of one single-loop controller only affects its specific zone.

Initial Configuration Complexity

While the hardware and wiring are simpler, the initial software configuration of a multi-loop system can be more involved than setting up several independent single-loop units. This often requires a more skilled technician or engineer for the initial setup.

Making the Right Choice for Your System

Selecting the correct control strategy depends entirely on the specific goals and scale of your application.

- If your primary focus is simplicity and robustness for a single zone: A dedicated single-loop controller remains the most direct and reliable solution.

- If your primary focus is managing a machine with multiple, coordinated zones: A multi-loop controller will dramatically reduce hardware cost, panel space, and wiring complexity.

- If your primary focus is system integration and data acquisition: The advanced communication capabilities of a multi-loop controller make it the superior choice for connecting to a larger plant control system.

Ultimately, selecting the correct control architecture is about aligning the controller's capabilities with the scale and complexity of your process.

Summary Table:

| Feature | Single-Loop Controller | Multi-Loop Controller |

|---|---|---|

| Architecture | One controller per zone | Centralized unit for multiple zones |

| Ideal For | Simple, single-zone applications | Complex machines with multiple heating zones |

| Hardware Footprint | Large (multiple devices) | Compact (single device) |

| Wiring & Integration | Complex, more components | Simplified, less wiring |

| Key Advantage | Robustness, zone isolation | Cost & space efficiency, advanced features |

| Key Disadvantage | Scalability issues | Single point of failure risk |

Ready to simplify your multi-zone thermal processes? KINTEK specializes in advanced lab equipment and industrial heating solutions. Our multi-loop temperature controllers are designed to reduce complexity, save space, and enhance integration for laboratories and industrial settings. Contact our experts today to find the perfect control solution for your application!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Multi-zone Laboratory Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Shaking Incubators for Diverse Laboratory Applications

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements