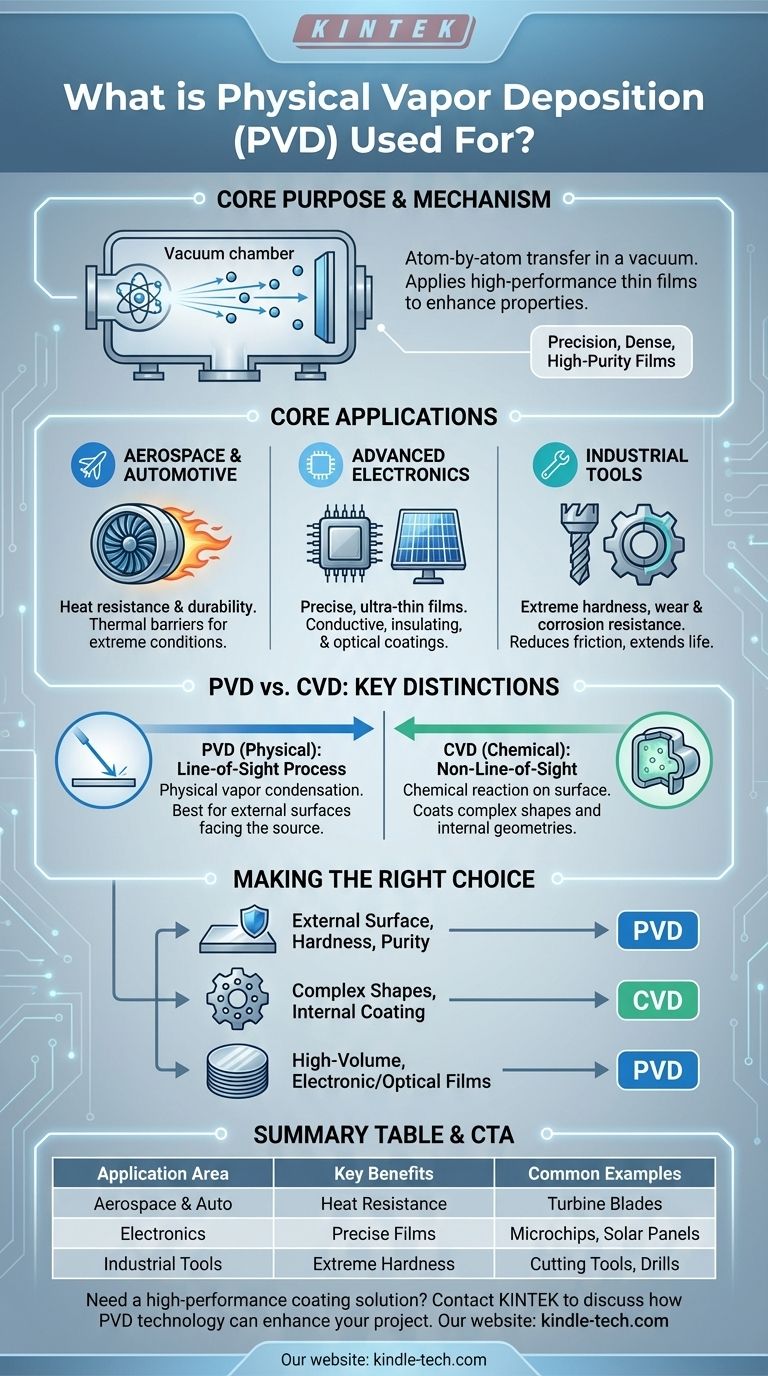

At its core, Physical Vapor Deposition (PVD) is used to apply high-performance thin films and coatings onto surfaces. This process enhances the object's properties, such as its durability, resistance to wear and temperature, or its optical characteristics. Key applications include coating aerospace components, manufacturing semiconductors and solar panels, and creating hard, corrosion-resistant layers on industrial tools.

The central purpose of PVD is to physically transfer a coating material atom-by-atom in a vacuum environment. This precision allows for the creation of extremely thin, dense, and high-purity films that are impossible to achieve with conventional methods like painting or plating.

Core Applications of PVD Explained

Physical Vapor Deposition is chosen when the performance and properties of a component's surface are critical to its function. The process is valued for its ability to create exceptionally high-quality coatings.

Enhancing Aerospace and Automotive Components

In aerospace, components are subjected to extreme temperatures and mechanical stress. PVD is used to apply dense, heat-resistant ceramic coatings that act as thermal barriers.

This dramatically improves the durability and lifespan of engine parts, turbine blades, and other critical elements operating in high-temperature environments.

Manufacturing Advanced Electronics

The semiconductor and solar industries rely on the precise application of ultra-thin films with specific optical or electrical properties. PVD is a cornerstone of this manufacturing process.

It is used to deposit the conductive and insulating layers on microchips or to apply anti-reflective coatings on solar panels, which maximizes their efficiency in converting light to energy.

Fortifying Tools and Equipment

For cutting tools, drills, and molds used in harsh industrial settings, wear and corrosion are primary causes of failure. PVD provides a solution by applying super-hard, low-friction coatings.

These coatings, often harder than the tool steel itself, significantly reduce wear, prevent corrosion, and allow machinery to operate at higher speeds and for longer periods without maintenance.

Understanding the Key Distinctions

While PVD is a powerful tool, it's essential to understand its characteristics in context. The most common alternative is Chemical Vapor Deposition (CVD), and their differences highlight the specific strengths of PVD.

The "Physical" Process

The name "Physical Vapor Deposition" describes its mechanism. The coating material is physically transformed into a vapor—often through evaporation (like boiling) or sputtering (like atomic sandblasting)—without a chemical reaction.

This vapor then travels in a straight line through a vacuum and condenses onto the target object, forming the thin film.

The Line-of-Sight Limitation

Because the vaporized material travels in a straight line, PVD is a line-of-sight process. This means it is exceptionally good at coating surfaces that directly face the vapor source.

However, it is less effective for coating the inside of complex shapes or hidden surfaces, as these areas are in a "shadow" and cannot be reached by the vapor.

The Chemical Alternative (CVD)

In contrast, Chemical Vapor Deposition (CVD) uses chemical reactions on the substrate's surface to form the coating. Precursor gases are introduced into a chamber, which then react to deposit the desired film.

Because this process relies on gas filling the entire chamber, CVD is a non-line-of-sight process. It excels at producing highly uniform coatings on all surfaces of an object, including complex internal geometries.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the component's geometry and the desired properties of the final coating.

- If your primary focus is applying an extremely hard, pure, or temperature-resistant coating to an external surface: PVD is the superior choice for its precision and high-quality results on line-of-sight applications.

- If your primary focus is creating a perfectly uniform coating on an object with complex shapes, holes, or internal channels: CVD is the better method due to its non-line-of-sight nature.

- If your primary focus is high-volume production of optical or electronic films on substrates like glass or wafers: PVD is the established, efficient, and highly controlled industry standard.

Ultimately, choosing between these technologies requires a clear understanding of your material, your component's shape, and the specific performance enhancement you need to achieve.

Summary Table:

| Application Area | Key Benefits of PVD | Common Examples |

|---|---|---|

| Aerospace & Automotive | Heat resistance, durability in extreme conditions | Turbine blades, engine components |

| Electronics & Semiconductors | Precise, ultra-thin films for conductivity & optics | Microchips, solar panels |

| Industrial Tools & Equipment | Extreme hardness, wear & corrosion resistance | Cutting tools, drills, molds |

Need a high-performance coating solution for your laboratory equipment or components? KINTEK specializes in precision lab equipment and consumables. Whether you're developing advanced materials or require durable coatings for your tools, our expertise can help you achieve superior results. Contact our experts today to discuss how PVD technology can enhance your project's performance and longevity.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing