In essence, plasma deposition of polymers is a vacuum-based process that uses an energized gas, or plasma, to decompose a precursor molecule (a monomer) and deposit it onto a surface as a highly customized, ultra-thin polymer film. Unlike conventional painting or dipping, this technique "grows" the polymer layer directly onto the part, resulting in a coating with fundamentally different and often superior properties.

The core challenge with traditional polymer coatings is achieving perfect adhesion and a defect-free finish, especially on complex shapes or sensitive materials. Plasma deposition solves this by building a polymer film from the molecular level up, creating an exceptionally thin, uniform, and tenaciously bonded layer that is impossible to form otherwise.

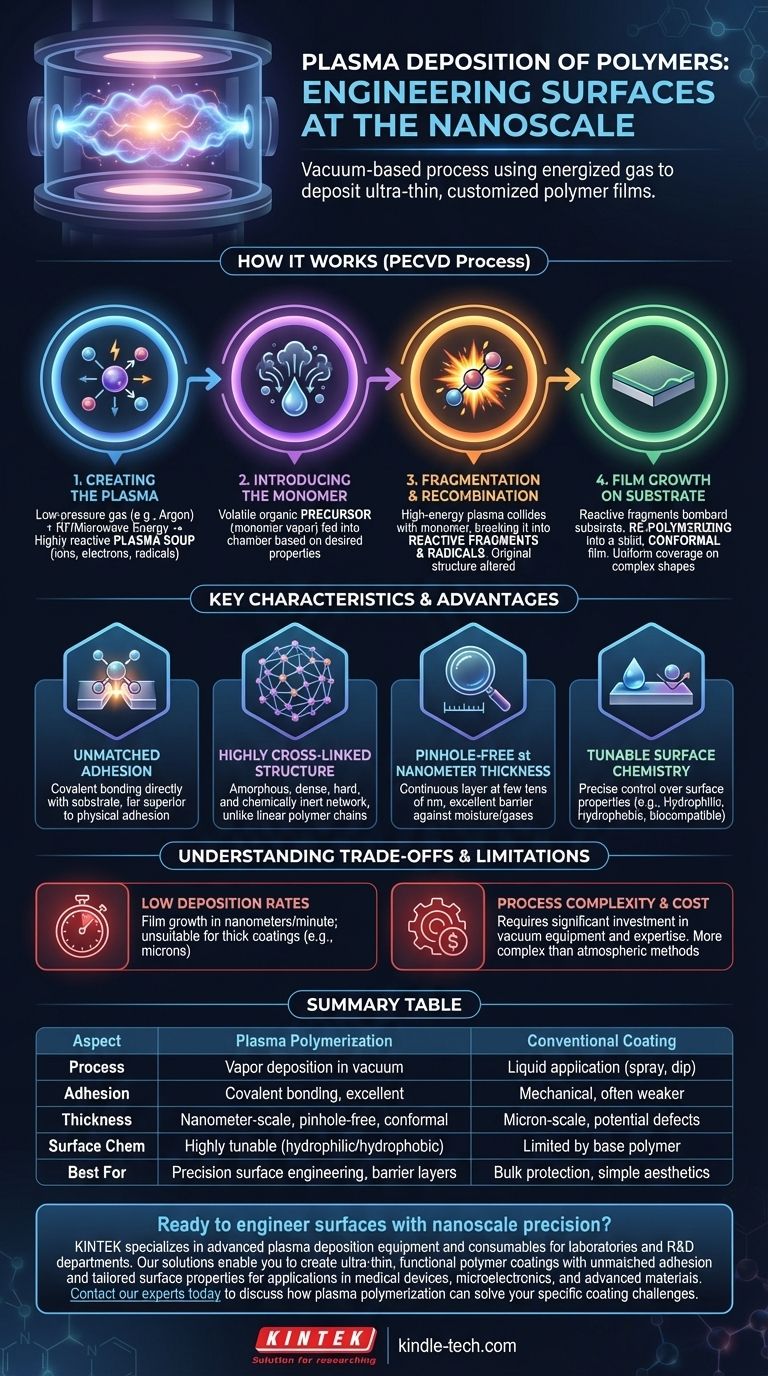

How the Plasma Deposition Process Works

At its heart, plasma deposition is a form of Plasma-Enhanced Chemical Vapor Deposition (PECVD) specifically tailored for creating polymer-like films. The entire process takes place inside a controlled vacuum chamber.

Step 1: Creating the Plasma

A low-pressure gas, typically an inert one like Argon, is introduced into the chamber. Radio Frequency (RF) or microwave energy is then applied, stripping electrons from the gas atoms. This creates a highly reactive soup of ions, electrons, free radicals, and neutral molecules known as a plasma, often called the fourth state of matter.

Step 2: Introducing the Monomer

A volatile organic precursor, the monomer, is then fed into the chamber as a vapor. This monomer is chosen based on the desired chemical properties of the final coating. For example, a fluorine-containing monomer might be used to create a hydrophobic (water-repelling) surface.

Step 3: Fragmentation and Recombination

The high-energy plasma collides with the monomer molecules, breaking them apart into smaller, highly reactive fragments and radicals. This is the key step that distinguishes plasma polymers from conventional ones; the original monomer structure is fundamentally altered.

Step 4: Film Growth on the Substrate

These reactive fragments bombard the target object (the substrate), which has been placed in the chamber. They react both with the substrate surface and with each other, re-polymerizing into a solid film. This "growth" process ensures the coating is conformal, meaning it uniformly covers even complex, three-dimensional geometries.

Key Characteristics of Plasma Polymers

The unique way plasma polymers are formed gives them a distinct set of properties not found in their conventional counterparts.

Unmatched Adhesion

The initial plasma environment effectively "cleans" and activates the substrate surface on a molecular level. As the film grows, it forms strong covalent bonds directly with the substrate, leading to adhesion that is far superior to physically applied coatings.

Highly Cross-Linked Structure

Unlike the long, linear chains of a typical polymer like polyethylene, a plasma-deposited polymer is an amorphous, highly cross-linked network. Imagine a tangled, three-dimensional web instead of parallel strands of spaghetti. This structure makes the films very dense, hard, and chemically inert.

Pinhole-Free at Nanometer Thickness

Because the film is built up from a vapor phase, it can achieve a completely continuous, pinhole-free layer at thicknesses of just a few tens of nanometers. This is critical for applications like creating barrier coatings against moisture or gases.

Tunable Surface Chemistry

By carefully selecting the monomer gas and adjusting process parameters like power and pressure, engineers can precisely tune the final surface properties. It's possible to create surfaces that are extremely hydrophilic (water-attracting), hydrophobic (water-repelling), or that possess specific chemical functional groups for binding to proteins or cells.

Understanding the Trade-offs and Limitations

While powerful, plasma deposition is not a universal solution. Its unique nature comes with specific trade-offs that make it unsuitable for certain applications.

Low Deposition Rates

This is a precision process, not a bulk one. Film growth is measured in nanometers per minute, making it impractical for creating thick coatings (e.g., several microns or more). It is exclusively a thin-film technology.

Process Complexity and Cost

Plasma deposition requires a significant capital investment in vacuum chambers, power supplies, and control systems. The process is more complex to run and scale compared to simple atmospheric methods like spray or dip coating.

Film Chemistry is Not the Monomer Chemistry

It is critical to understand that the deposited film does not retain the chemical structure of the starting monomer. The plasma scrambles the molecules. For example, depositing a film from a hexane monomer does not produce a "polyhexane" film, but rather a hydrogenated amorphous carbon film (a-C:H) with a C:H ratio that depends on process conditions. This can be a benefit for creating novel materials but a drawback if preserving a specific polymer chemistry is required.

When to Choose Plasma Polymerization

Your decision to use plasma deposition should be driven by a specific surface engineering goal that conventional methods cannot achieve.

- If your primary focus is creating advanced biocompatible surfaces: Use plasma deposition to precisely add functional groups that promote or prevent cell adhesion for medical implants, biosensors, or cell cultureware.

- If your primary focus is barrier protection for sensitive components: This method is ideal for creating ultra-thin, pinhole-free hydrophobic coatings that protect microelectronics or optics from moisture without adding bulk.

- If your primary focus is modifying surface energy for fluid control: Plasma deposition is unmatched for creating highly controlled hydrophilic or hydrophobic surfaces for microfluidic devices, self-cleaning textiles, or anti-fogging applications.

- If your primary focus is a simple, thick, protective coating: This method is not the right choice; consider conventional techniques like powder coating, painting, or e-coating that are better suited for bulk material deposition.

Ultimately, plasma polymerization is a powerful tool for engineering surfaces with properties that are dictated by their nanoscale structure, not just their bulk material.

Summary Table:

| Aspect | Plasma Polymerization | Conventional Coating |

|---|---|---|

| Process | Vapor deposition in a vacuum chamber | Liquid application (spray, dip) |

| Adhesion | Covalent bonding, excellent | Mechanical, often weaker |

| Thickness & Uniformity | Nanometer-scale, pinhole-free, conformal | Micron-scale, potential for defects |

| Surface Chemistry | Highly tunable (hydrophilic/hydrophobic) | Limited by base polymer chemistry |

| Best For | Precision surface engineering, barrier layers | Bulk protection, simple aesthetics |

Ready to engineer surfaces with nanoscale precision?

KINTEK specializes in advanced plasma deposition equipment and consumables for laboratories and R&D departments. Our solutions enable you to create ultra-thin, functional polymer coatings with unmatched adhesion and tailored surface properties for applications in medical devices, microelectronics, and advanced materials.

Contact our experts today to discuss how plasma polymerization can solve your specific coating challenges.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application