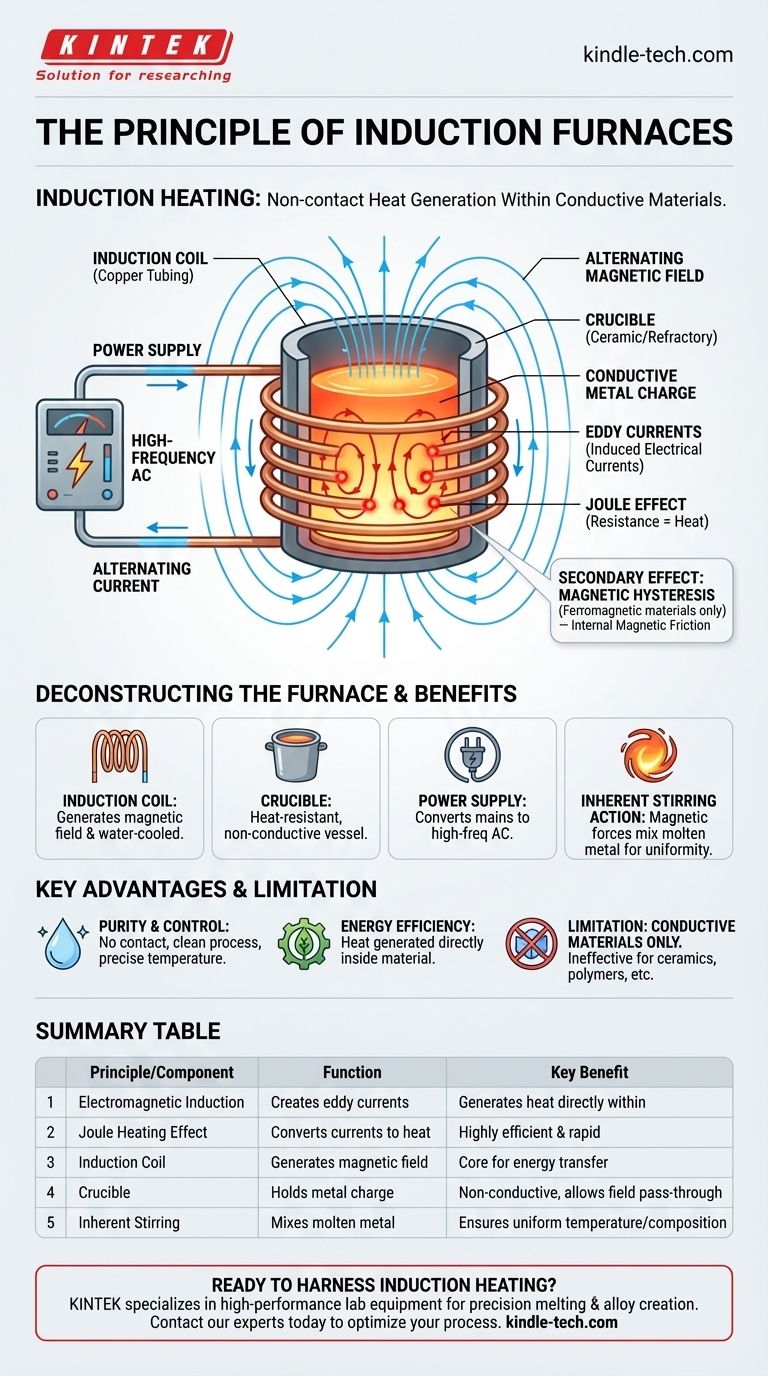

The fundamental principle behind an induction furnace is induction heating. This is a non-contact process where an alternating magnetic field is used to generate heat directly within an electrically conductive material. It achieves this by combining two core physical phenomena: electromagnetic induction, which creates electrical currents in the target material, and the Joule effect, where the material's own resistance converts that electrical energy into heat.

An induction furnace does not use an external flame or heating element. Instead, it generates a powerful magnetic field that induces electrical currents inside the metal itself. The metal's natural resistance to these internal currents is what produces rapid, precise, and clean heat.

The Two Core Physical Principles at Play

To truly understand how an induction furnace works, you need to grasp the two distinct physical laws that make it possible. These principles work in tandem to convert electrical energy into thermal energy with remarkable efficiency.

Principle 1: Electromagnetic Induction

An alternating current (AC) is passed through a primary coil, which is typically made of copper tubing. According to Faraday's Law of Induction, this creates a powerful and rapidly changing magnetic field around the coil.

When a conductive material, such as a piece of metal, is placed inside this magnetic field, the field induces a voltage within it. This induced voltage drives strong, swirling electrical currents inside the metal, known as eddy currents.

Principle 2: The Joule Heating Effect

The induced eddy currents are not flowing through a perfect conductor; the metal has inherent electrical resistance. The Joule effect (or Joule heating) describes how the energy of these flowing currents is converted into heat as they overcome this resistance.

This is the primary source of heat in an induction furnace. Because the heat is generated within the material, the process is incredibly fast and efficient, with minimal energy lost to the surrounding environment.

A Secondary Effect: Magnetic Hysteresis

For ferromagnetic materials like iron, there is an additional source of heat. The rapidly changing magnetic field causes the magnetic domains within the iron to quickly flip their orientation back and forth.

This internal friction generates a significant amount of supplemental heat, a phenomenon known as magnetic hysteresis loss. This makes induction heating particularly effective for iron-based metals.

Deconstructing the Induction Furnace

The physical components of an induction furnace are direct applications of these principles. Each part serves a specific function in generating and containing the process.

The Induction Coil

This is the heart of the furnace. It's a hollow copper tube, often wound into a helical shape, through which both the high-frequency AC and cooling water flow. Its sole purpose is to generate the changing magnetic field.

The Crucible

The crucible is the refractory (heat-resistant) vessel that holds the metal charge. It is made of a non-conductive material, such as ceramic or graphite composite, to ensure that the magnetic field passes through it and only heats the conductive metal inside.

The Power Supply

This sophisticated electronic system converts standard mains electricity into the high-frequency, high-current AC required to drive the induction coil effectively. It is the brain that controls the entire heating process.

The Inherent Stirring Action

A key benefit of the induction process is the natural stirring action it creates. The same magnetic forces that induce eddy currents also exert a force on the molten metal, causing it to stir continuously. This ensures excellent temperature and compositional uniformity, which is critical for creating high-quality alloys.

Understanding the Trade-offs and Advantages

No technology is perfect for every application. Understanding the distinct advantages and limitations of induction heating is crucial for determining its suitability.

Key Advantage: Purity and Control

Because there is no contact between a heating element and the material, and no combustion byproducts, the process is exceptionally clean. This prevents contamination, which is vital for specialty alloys and precious metals. Temperature can also be controlled with extreme precision.

Key Advantage: Energy Efficiency

Heat is generated directly where it is needed—inside the workpiece. This results in much higher energy efficiency and a faster time-to-melt compared to methods that heat a chamber and rely on radiation or convection to transfer heat to the material.

The Main Limitation: Conductive Materials Only

The principle of induction heating fundamentally relies on the material being an electrical conductor. The process is ineffective for heating non-conductive materials like ceramics, glass, or polymers.

When Is an Induction Furnace the Right Choice?

Your decision to use an induction furnace should be driven by the specific requirements of your material and process goal.

- If your primary focus is alloy purity and uniformity: The clean, non-contact heating and inherent stirring action make it the ideal choice for producing high-quality, homogenous metal alloys.

- If your primary focus is rapid, precise heating for specific processes: For applications like surface hardening, brazing, or shrink-fitting, the speed and pinpoint control of induction heating are unparalleled.

- If your primary focus is melting high-value or reactive metals: The ability to operate in a controlled vacuum or inert atmosphere makes induction furnaces essential for preventing oxidation of precious or reactive materials like titanium.

Ultimately, the principle of induction provides a remarkably clean, efficient, and controllable method for transforming electrical energy into thermal energy directly within a material.

Summary Table:

| Principle/Component | Function | Key Benefit |

|---|---|---|

| Electromagnetic Induction | Creates eddy currents inside the metal | Generates heat directly within the material |

| Joule Heating Effect | Converts electrical currents into heat | Highly efficient and rapid heating |

| Induction Coil | Generates the alternating magnetic field | Core component for energy transfer |

| Crucible | Holds the metal charge | Non-conductive, allowing field to pass through |

| Inherent Stirring | Mixes molten metal via magnetic forces | Ensures uniform temperature and composition |

Ready to harness the power of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precision melting, alloy creation, and heat treatment. Our solutions deliver the purity, control, and efficiency your research or production demands.

Contact our experts today to discuss how an induction furnace can optimize your specific metalworking processes and achieve superior results.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.