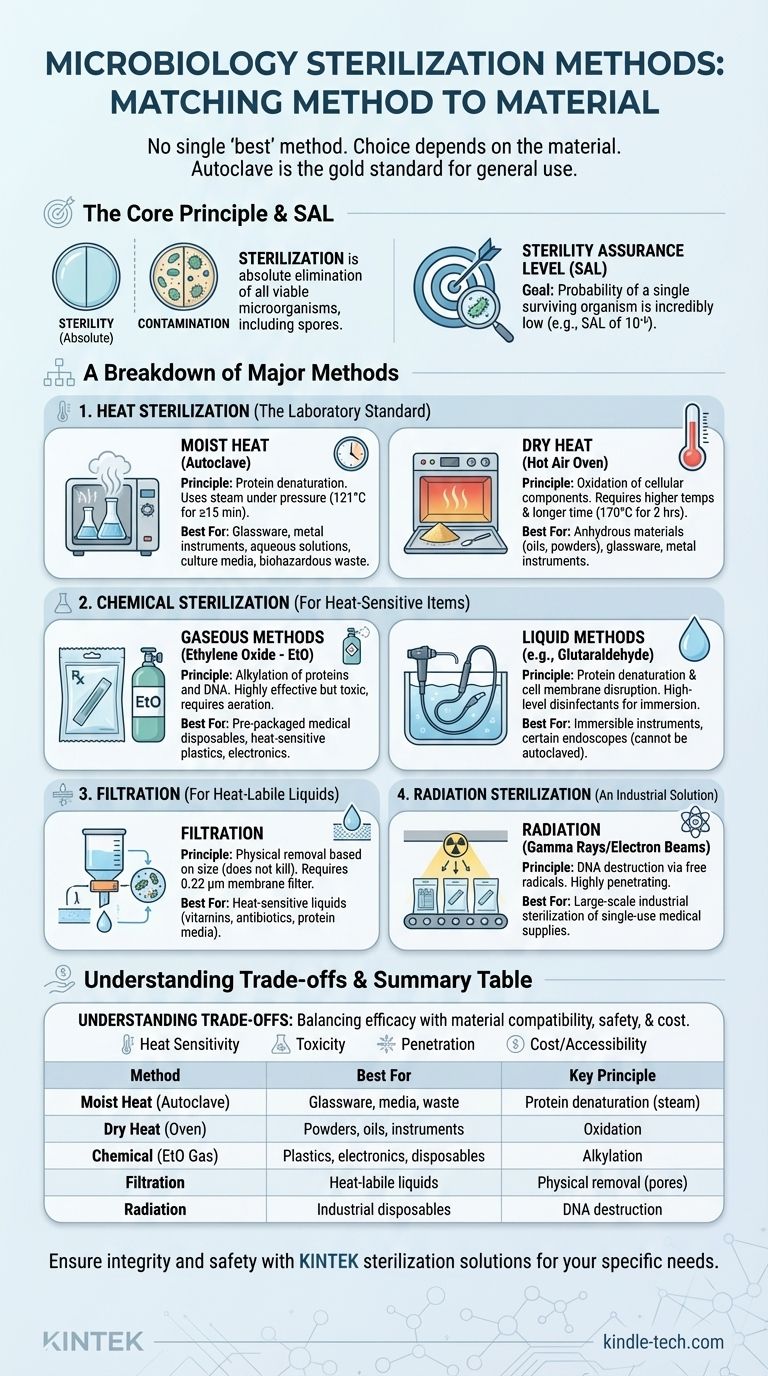

The definitive answer is that there is no single "best" method for all applications in microbiology. The optimal choice is entirely dependent on the material you need to sterilize. However, for the vast majority of general laboratory purposes, moist heat sterilization via an autoclave is considered the gold standard due to its high efficacy, reliability, and speed.

The core principle of sterilization is not finding one perfect tool, but rather matching the method to the material. While the autoclave is the workhorse for durable items, heat-sensitive materials demand fundamentally different approaches like filtration or chemical sterilization to prevent their destruction.

The Core Principle: Sterility vs. Contamination

Sterilization is an absolute process. It is the complete elimination or destruction of all viable microorganisms, including bacteria, viruses, and resilient bacterial spores. This is distinct from disinfection, which only reduces the number of pathogenic organisms to a safe level.

Why Sterilization is Non-Negotiable

In microbiology, accuracy is everything. A single contaminating microbe from the air, a tool, or a previous experiment can multiply rapidly and completely invalidate your results.

This is why sterilization is critical for two key functions: preventing inbound contamination of your experiment and preventing outbound contamination of the lab environment with potentially hazardous biological waste.

The Goal: Sterility Assurance Level (SAL)

Sterilization operates on a principle of logarithmic reduction. The goal is to reduce the microbial population to a point where the probability of a single surviving organism is incredibly low.

This is measured by the Sterility Assurance Level (SAL). A SAL of 10⁻⁶, common for medical devices, means there is a one-in-a-million chance of a single viable microbe remaining on an item after the process is complete.

A Breakdown of Major Sterilization Methods

Choosing the right method requires understanding how each one works and what materials it is compatible with. The primary dividing line is a material's tolerance for heat and moisture.

1. Heat Sterilization: The Laboratory Standard

Heat kills microorganisms by denaturing their essential proteins and enzymes. It is the most common and reliable method used in labs.

Moist Heat (Autoclaving) An autoclave works like a sophisticated pressure cooker. It uses steam heated under pressure to a typical temperature of 121°C (250°F) for at least 15 minutes. The pressure allows the steam to reach temperatures above the boiling point of water, and the moisture rapidly transfers heat and penetrates microbial cells.

- Best for: Glassware, metal instruments, aqueous solutions, culture media, and biohazardous waste.

- Principle: Protein denaturation.

Dry Heat (Hot Air Oven) Dry heat sterilization requires higher temperatures and much longer exposure times, typically 170°C (340°F) for 2 hours. It kills microbes through oxidation.

- Best for: Anhydrous (water-free) materials like oils and powders, glassware, and metal instruments that could be corroded by steam.

- Principle: Oxidation of cellular components.

2. Chemical Sterilization: For Heat-Sensitive Items

When an item cannot withstand the high temperatures of an autoclave, chemical agents are used.

Gaseous Methods (Ethylene Oxide - EtO) Ethylene oxide gas is a highly effective agent that can sterilize heat- and moisture-sensitive items like plastics and electronics. It works by disrupting the DNA and proteins of microbes.

- Best for: Pre-packaged medical disposables (syringes, catheters), petri dishes, and complex electronic or medical devices.

- Principle: Alkylation of proteins and DNA.

Liquid Methods (Glutaraldehyde, Peracetic Acid) These are high-level disinfectants that can achieve sterilization if an item is fully immersed for a sufficient period (often many hours).

- Best for: Sterilizing immersible instruments that cannot be autoclaved, such as certain endoscopes.

- Principle: Varies by chemical, but generally involves protein denaturation and cell membrane disruption.

3. Filtration: For Heat-Labile Liquids

Filtration does not kill microbes; it physically removes them. A liquid is passed through a membrane filter with a pore size small enough to trap bacteria, typically 0.22 micrometers (µm).

- Best for: Heat-sensitive liquids like vitamin solutions, antibiotic preparations, and cell culture media containing proteins.

- Principle: Physical removal based on size.

4. Radiation Sterilization: An Industrial Solution

Ionizing radiation, such as gamma rays or electron beams, destroys microbial DNA. This is a highly effective and penetrating method used for large-scale, industrial sterilization.

- Best for: Industrial sterilization of single-use medical supplies (gloves, syringes) and some pharmaceuticals.

- Principle: DNA destruction via free radicals.

Understanding the Trade-offs

No method is perfect. Your choice involves balancing efficacy with material compatibility, safety, and accessibility.

Heat & Moisture Sensitivity is Key

This is the primary decision point. An autoclave will destroy many plastics and degrade sensitive chemicals. Attempting to autoclave a heat-labile vitamin solution renders it useless. You must know what your material can tolerate.

Chemical Toxicity and Residues

Methods like Ethylene Oxide are extremely effective but are also toxic and carcinogenic. Items sterilized with EtO require a lengthy aeration period to remove residual gas before they are safe to handle.

Penetration vs. Surface Treatment

Moist heat penetrates dense materials and packed loads far more effectively than dry heat. Filtration only works for liquids. Gaseous methods require that the gas can reach every single surface to be effective.

Cost and Accessibility

Autoclaves and dry heat ovens are standard equipment in almost any microbiology lab. In contrast, radiation and EtO sterilization facilities are highly specialized, expensive industrial operations. Filtration is simple and cheap for small volumes but impractical for large ones.

How to Select the Correct Sterilization Method

Use this guide to make a clear decision based on your specific task.

- If you are sterilizing durable lab equipment (glassware, metal tools), culture media, or biohazardous waste: Autoclaving (moist heat) is your most reliable and efficient choice.

- If you are sterilizing heat-sensitive plastics, electronics, or pre-packaged disposables: Chemical sterilization (like Ethylene Oxide) or radiation is the industrial standard, and these items are typically purchased pre-sterilized.

- If you are sterilizing heat-labile liquids like antibiotic solutions or protein media: Filtration is the only appropriate method to maintain the solution's integrity.

- If you are sterilizing anhydrous materials like oils, powders, or moisture-sensitive instruments: Dry heat is superior, as moist heat cannot penetrate these substances effectively.

By matching the sterilization method to the material, you ensure the integrity of your science and the safety of your laboratory.

Summary Table:

| Method | Best For | Key Principle |

|---|---|---|

| Moist Heat (Autoclave) | Glassware, metal instruments, culture media, waste | Protein denaturation with steam |

| Dry Heat (Oven) | Powders, oils, moisture-sensitive items | Oxidation of cellular components |

| Chemical (EtO Gas) | Heat-sensitive plastics, electronics, disposables | Alkylation of proteins and DNA |

| Filtration | Heat-labile liquids (antibiotics, media) | Physical removal via membrane pores |

| Radiation | Industrial sterilization of disposables | DNA destruction via ionizing radiation |

Ensure the integrity of your experiments and the safety of your lab with the right sterilization equipment from KINTEK.

Whether you need a reliable autoclave for your glassware, a dry heat oven for powders, or filtration systems for sensitive liquids, KINTEK provides high-quality lab equipment and consumables tailored to your microbiology needs. Our experts can help you select the perfect solution to match your materials and protocols.

Contact our team today to discuss your laboratory's sterilization requirements and enhance your workflow efficiency and reliability.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- How does the lab autoclave work? Achieve Complete Sterilization with High-Pressure Steam

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety