The correct shutdown procedure is a deliberate sequence designed to systematically eliminate hazards. After completing your experiment, you must first turn off the main power supply. Next, physically remove the electrolytic cell from any environmental controls, such as a constant temperature water bath. Only after the cell is clear should you turn off the water bath and proceed with disassembly.

The shutdown sequence is not arbitrary; it follows a critical hierarchy of risk mitigation. Always address the most immediate and dangerous hazard—electricity—first, before moving on to thermal, mechanical, and chemical clean-up.

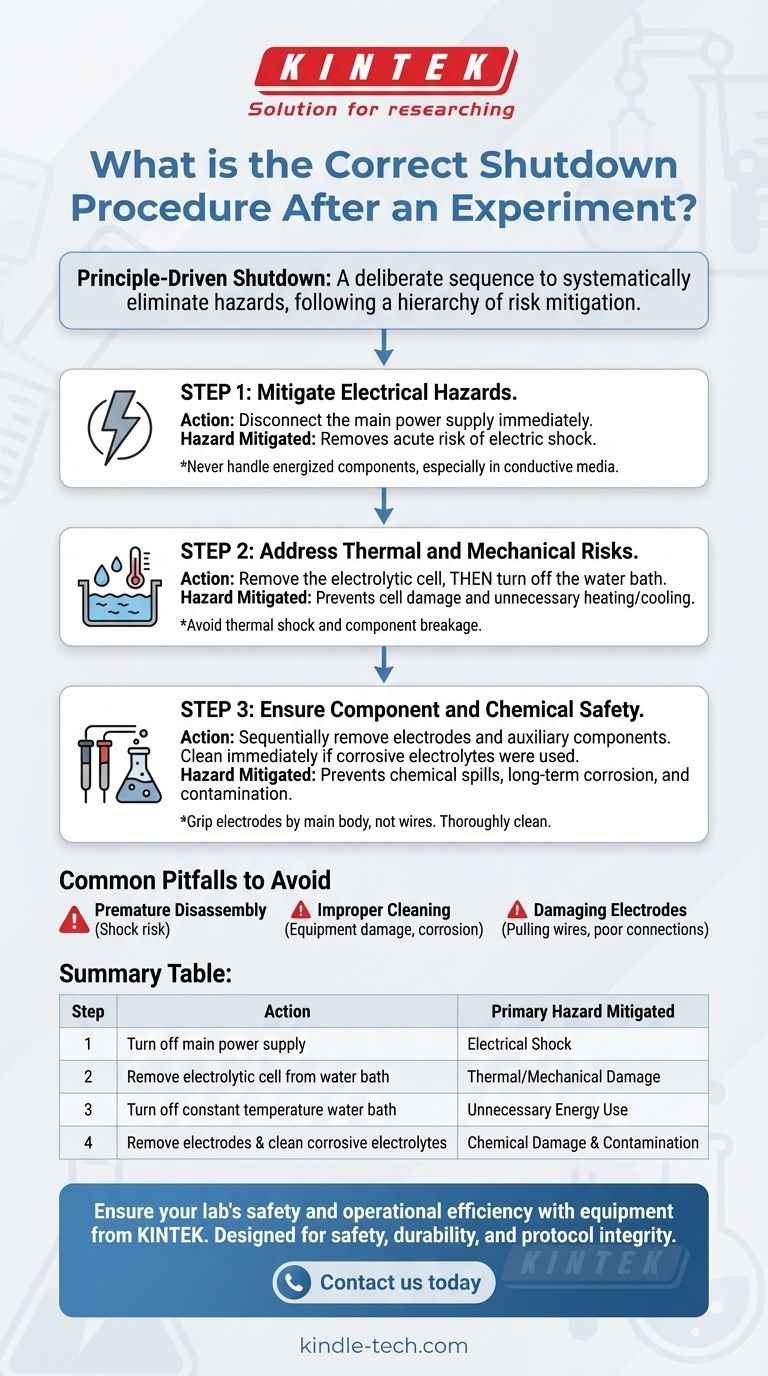

The Principle-Driven Shutdown Sequence

A proper shutdown is more than a checklist; it's a mental model for managing risk. The correct order ensures that you are never handling energized or environmentally controlled equipment, which minimizes the potential for accidents.

Step 1: Mitigate Electrical Hazards

The absolute first step is to disconnect the power supply. This immediately removes the risk of electric shock, which is the most acute danger in this type of setup.

Handling any component, especially one submerged in a conductive medium like a water bath, while power is active is a significant safety violation.

Step 2: Address Thermal and Mechanical Risks

Once the system is de-energized, you can safely interact with it. Remove the electrolytic cell from the constant temperature water bath.

This step prevents two potential issues: accidentally breaking the cell while it's still connected to other equipment, and leaving the cell to be heated or cooled unnecessarily by the water bath.

After the cell is removed and safely stowed, you can turn off the water bath.

Step 3: Ensure Component and Chemical Safety

With the primary hazards neutralized, focus on the equipment itself. Sequentially remove electrodes and other auxiliary components from the cell.

When handling electrodes, grip them by their main body, not by their wires. Pulling the wires can damage the sensitive connection terminals, compromising future experiments.

If you used corrosive or toxic electrolytes, such as strong acids or bases, immediate and thorough cleaning is critical. This must be done before disassembling the cell from its stand to prevent chemical spills and long-term corrosion of lab equipment.

Common Pitfalls to Avoid

Understanding what can go wrong reinforces why the correct procedure is so important. Deviating from the sequence introduces unnecessary risks to both you and the equipment.

The Risk of Premature Disassembly

Attempting to remove the cell or its electrodes while the power is still on creates a direct path for electric shock. This is the single most dangerous mistake you can make during shutdown.

The Consequence of Improper Cleaning

Leaving residual corrosive electrolytes in the cell can cause significant damage. It will eat away at the cell components and mounting hardware over time, leading to equipment failure and costly replacements.

The Danger of Damaging Electrodes

Improperly removing electrodes by pulling on their wires is a common source of equipment failure. Damaged terminals lead to unreliable connections, poor data quality, and the need for premature replacement.

Making the Right Choice for Your Goal

Adhering to the proper shutdown sequence is non-negotiable, but understanding the motivation behind each step helps reinforce the habit.

- If your primary focus is personal safety: Always follow the Power -> Remove Cell -> Deactivate Bath sequence to eliminate electrical and thermal hazards in the correct order.

- If your primary focus is equipment longevity: Pay meticulous attention to cleaning corrosive materials immediately and handling all components, especially electrode wires, with care.

- If your primary focus is data integrity: Ensure the thorough cleaning of all components to prevent chemical cross-contamination that could invalidate future experimental results.

Following this structured, principle-based approach ensures the safety of the operator, the integrity of the equipment, and the reliability of your future work.

Summary Table:

| Step | Action | Primary Hazard Mitigated |

|---|---|---|

| 1 | Turn off main power supply | Electrical Shock |

| 2 | Remove electrolytic cell from water bath | Thermal/Mechanical Damage |

| 3 | Turn off constant temperature water bath | Unnecessary Energy Use |

| 4 | Remove electrodes & clean corrosive electrolytes | Chemical Damage & Contamination |

Ensure your lab's safety and operational efficiency with equipment from KINTEK.

Following the correct shutdown procedure is crucial, but it starts with having reliable, well-designed lab equipment. KINTEK specializes in high-quality lab equipment and consumables, designed with safety and durability in mind. Our products help you maintain protocol integrity and protect your valuable research.

Contact us today to find the right equipment for your laboratory needs and enhance your lab's safety standards. Get in touch via our Contact Form to speak with an expert.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Nickel Aluminum Tabs for Soft Pack Lithium Batteries

- High Purity Zinc Foil for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

People Also Ask

- How is a three-electrode electrochemical electrolytic cell utilized to evaluate Zr-Nb alloy corrosion resistance?

- What is the volume range of the coating evaluation electrolytic cell? A Guide to Choosing the Right Size

- What type of electrode system is the coating evaluation electrolytic cell designed for? Unlock Precise Coating Analysis

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis

- What is the operating principle of a flat plate corrosion electrolytic cell? A Guide to Controlled Materials Testing