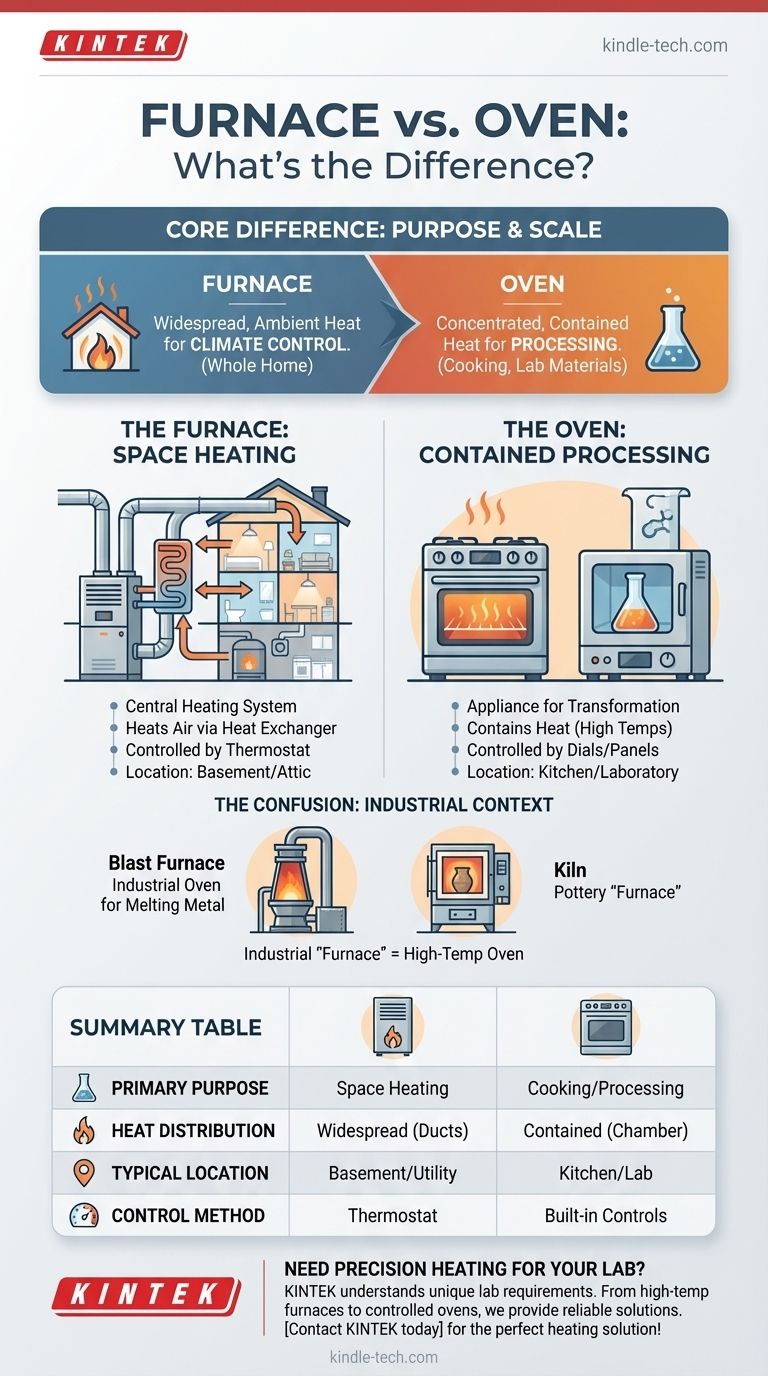

In everyday terms, a furnace heats your entire home, while an oven heats the food inside it. A furnace is a core component of a home's central heating system, designed to control the climate of a large space. An oven is a kitchen appliance, an enclosed chamber designed to cook, bake, or roast items at a specific temperature.

The fundamental difference is not the technology of heating, but the purpose and scale. A furnace provides widespread, ambient heat for climate control, while an oven delivers concentrated, contained heat for processing materials or food.

The Role of the Furnace: Space Heating

A furnace is the primary heat generator in most forced-air HVAC (Heating, Ventilation, and Air Conditioning) systems. Its single job is to make a large, inhabited space comfortable.

A Central Component of Your Home

The furnace is typically a large metal cabinet located in a basement, closet, or attic. It's not an appliance you interact with daily; you control it remotely via a thermostat.

How It Distributes Heat

A furnace works by heating air, not objects directly. It burns fuel (like natural gas or oil) or uses electric resistance coils to warm a metal component called a heat exchanger. A powerful blower fan then pushes cool air from your home across the hot exchanger, and the newly warmed air is distributed throughout the house via a system of ducts and vents.

The Role of the Oven: Contained Processing

An oven is an insulated chamber designed to heat its contents to a precise, controlled temperature. Its purpose is to induce a physical or chemical change, most commonly cooking.

An Appliance for Transformation

Unlike a furnace, which disperses heat, an oven's goal is to contain heat effectively. This allows it to reach temperatures much higher than what is needed for simple space heating, enabling processes like baking, roasting, and broiling.

How It Concentrates Heat

Ovens use gas burners or electric heating elements located within the insulated box. Heat is transferred to the food through a combination of convection (circulating hot air), conduction (from the pan), and radiation (from the hot interior walls and elements).

Where the Confusion Comes From

The terms can become muddled in industrial and historical contexts, which is often the source of the misunderstanding.

The Industrial Exception

In manufacturing and metallurgy, the term "furnace" is used to describe a high-temperature industrial oven. A blast furnace, for example, is a massive structure used to smelt iron ore—functionally, it's a powerful oven designed to melt metal. Pottery is fired in a type of industrial oven called a kiln, which is technically a furnace.

The "Oven" Within a Furnace

In some older or highly technical schematics, the combustion chamber inside a home furnace might be referred to as its "oven." However, in modern, everyday language, this usage is obsolete and confusing.

The Defining Factor: Intent

For all practical, non-industrial purposes, the distinction is clear. If the intent is to heat a room or building, it's a furnace. If the intent is to cook or bake something inside an enclosed box, it's an oven.

How to Use the Terms Correctly

Use this simple guide to choose the right word every time.

- If your primary focus is heating your house: The appliance in your basement or utility closet is your furnace.

- If your primary focus is cooking a meal: The appliance in your kitchen for baking and roasting is your oven.

- If you are describing an industrial process like melting steel: You are likely referring to an industrial furnace.

Understanding this core distinction in purpose removes all ambiguity between these two essential appliances.

Summary Table:

| Feature | Furnace | Oven |

|---|---|---|

| Primary Purpose | Space heating (climate control) | Cooking, baking, material processing |

| Heat Distribution | Widespread, ambient (via ducts) | Contained, concentrated (within chamber) |

| Typical Location | Basement, utility closet, attic | Kitchen, laboratory |

| Control Method | Thermostat | Built-in temperature dials/controls |

Need Precision Heating Equipment for Your Lab?

Just as a furnace and oven serve distinct purposes, KINTEK understands that every laboratory has unique heating requirements. Whether you need a high-temperature furnace for material processing or a controlled oven for sample preparation, KINTEK provides reliable, efficient lab equipment tailored to your needs. Our expertise ensures you get the right tool for the job, enhancing your research and productivity.

Contact KINTEK today to find the perfect heating solution for your laboratory!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary use of furnace in the chemical industry? Master Thermal Treatment for Material Transformation

- What is the cooling rate for a muffle furnace? Achieve Optimal Cooling for Your Lab Processes

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- At what temperature does quartz soften? Understand the practical limits for lab equipment

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating