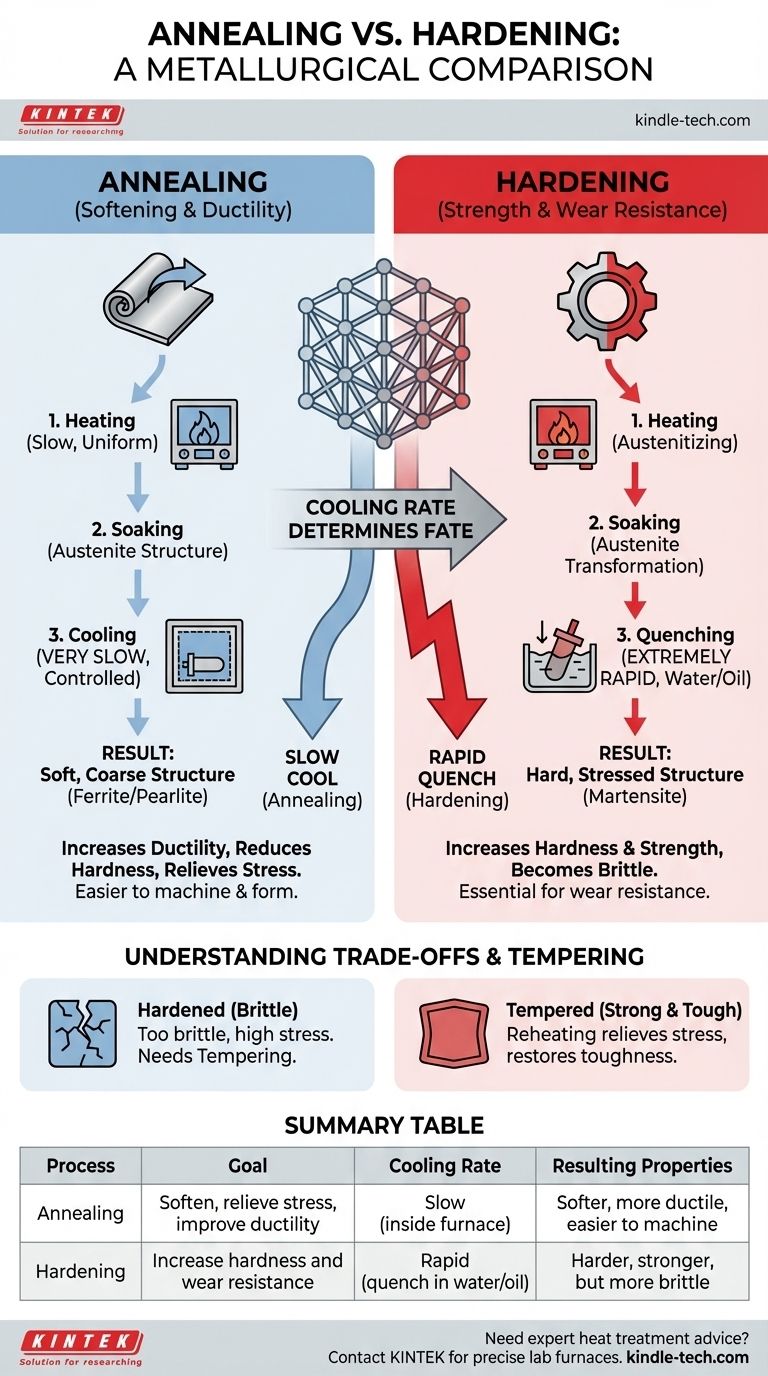

At their core, annealing and hardening are opposing metallurgical processes. Annealing makes a metal softer, more ductile, and easier to work with by heating it and then cooling it very slowly. Hardening achieves the opposite; it makes a metal significantly harder and stronger, but also more brittle, by heating it and then cooling it extremely rapidly.

The fundamental difference lies in the cooling rate after heating. Annealing uses a slow, controlled cool to achieve a soft and stable internal structure, while hardening uses a rapid quench to lock in a hard, highly stressed structure.

The Goal of Annealing: To Soften and Relieve Stress

Annealing is a preparatory or corrective process. Its purpose is to return a metal to a workable state, making subsequent manufacturing steps easier and more predictable.

What is Annealing?

Annealing is a heat treatment process that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness.

This makes the material easier to machine, form, or stamp without fracturing. It also serves to relieve internal stresses that may have built up from previous processes like welding or cold working.

The Annealing Process

The process involves three main stages:

- Heating: The metal is heated slowly and uniformly to a specific temperature, typically above its upper critical temperature (Ac3).

- Soaking: It is held at this temperature for a set amount of time to ensure the entire part reaches a stable, uniform structure called austenite.

- Cooling: It is then cooled at a very slow, controlled rate, often by simply turning the furnace off and letting the part cool inside it over many hours.

The Resulting Properties

This slow cooling allows the metal's internal crystal structure to rearrange into a soft, coarse state (like ferrite and pearlite). The primary outcomes are significantly increased ductility, reduced hardness, and improved toughness.

The Goal of Hardening: To Increase Strength and Wear Resistance

Hardening is a finishing process. Its purpose is to impart the final desired mechanical properties, such as high strength and resistance to wear, to a finished or near-finished part.

What is Hardening?

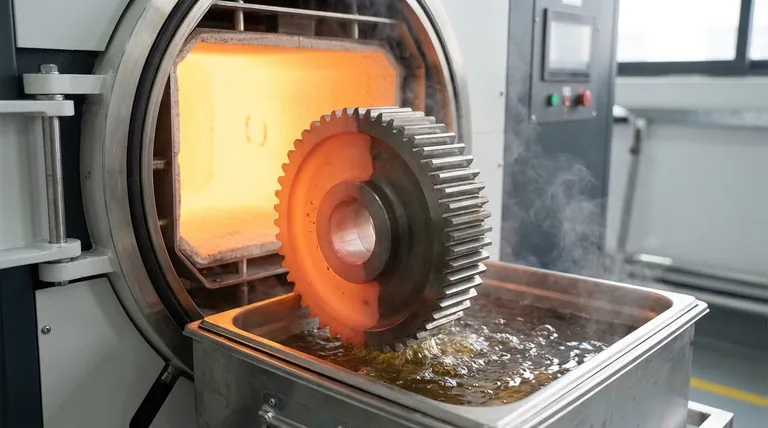

Hardening is a process used almost exclusively on medium-to-high carbon steels and certain alloy steels to dramatically increase their hardness and tensile strength.

This is essential for components that need to resist abrasion, cutting, or deformation under load, such as gears, cutting tools, and bearings.

The Hardening Process

The first two steps are similar to annealing, but the final step is drastically different:

- Heating: The steel is heated to its austenitizing temperature.

- Soaking: It is held at this temperature to ensure a complete transformation to austenite.

- Quenching: It is then cooled extremely rapidly by plunging it into a medium like water, oil, or brine.

The Resulting Properties

This rapid quench does not give the crystal structure time to rearrange. Instead, it traps it in a highly stressed, distorted, needle-like structure called martensite. The result is a material with extremely high hardness and strength but very low ductility, making it brittle.

Understanding the Trade-offs

Neither process is a complete solution on its own. They are tools used to manipulate a material's properties, and each comes with inherent compromises.

The Brittleness Problem of Hardening

A part that has only been hardened is often too brittle for any practical application. The immense internal stresses created by quenching can cause it to crack or shatter under impact or even spontaneously.

The Necessity of Tempering

Because of this brittleness, hardened parts are almost always subjected to a secondary heat treatment called tempering. This involves reheating the part to a much lower temperature to relieve the quenching stresses and restore some toughness, albeit with a minor sacrifice in peak hardness.

The Strength Limitation of Annealing

An annealed part is in its softest, most workable state. While perfect for manufacturing, it lacks the strength and wear resistance required for high-performance applications. It is a means to an end, not typically the final state for a load-bearing component.

Making the Right Choice for Your Goal

Your choice between these processes depends entirely on what you need to achieve with the material at a specific stage of production.

- If your primary focus is machinability or formability: Annealing is the correct choice to prepare the material for subsequent manufacturing steps.

- If your primary focus is final strength and wear resistance: Hardening, followed by tempering, is necessary to achieve the desired performance of the finished part.

- If your primary focus is simply to remove stress from welding or forming: A specific type of annealing, known as stress-relief annealing, is the appropriate process.

Ultimately, understanding the direct relationship between cooling rate, internal structure, and final properties is the key to mastering heat treatment.

Summary Table:

| Process | Goal | Cooling Rate | Resulting Properties |

|---|---|---|---|

| Annealing | Soften, relieve stress, improve ductility | Slow (inside furnace) | Softer, more ductile, easier to machine |

| Hardening | Increase hardness and wear resistance | Rapid (quench in water/oil) | Harder, stronger, but more brittle |

Need expert advice on heat treatment for your lab or production process? KINTEK specializes in the precise lab equipment, including furnaces for annealing and hardening, needed to achieve your material property goals. Our team can help you select the right tools for your specific metals and applications. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space