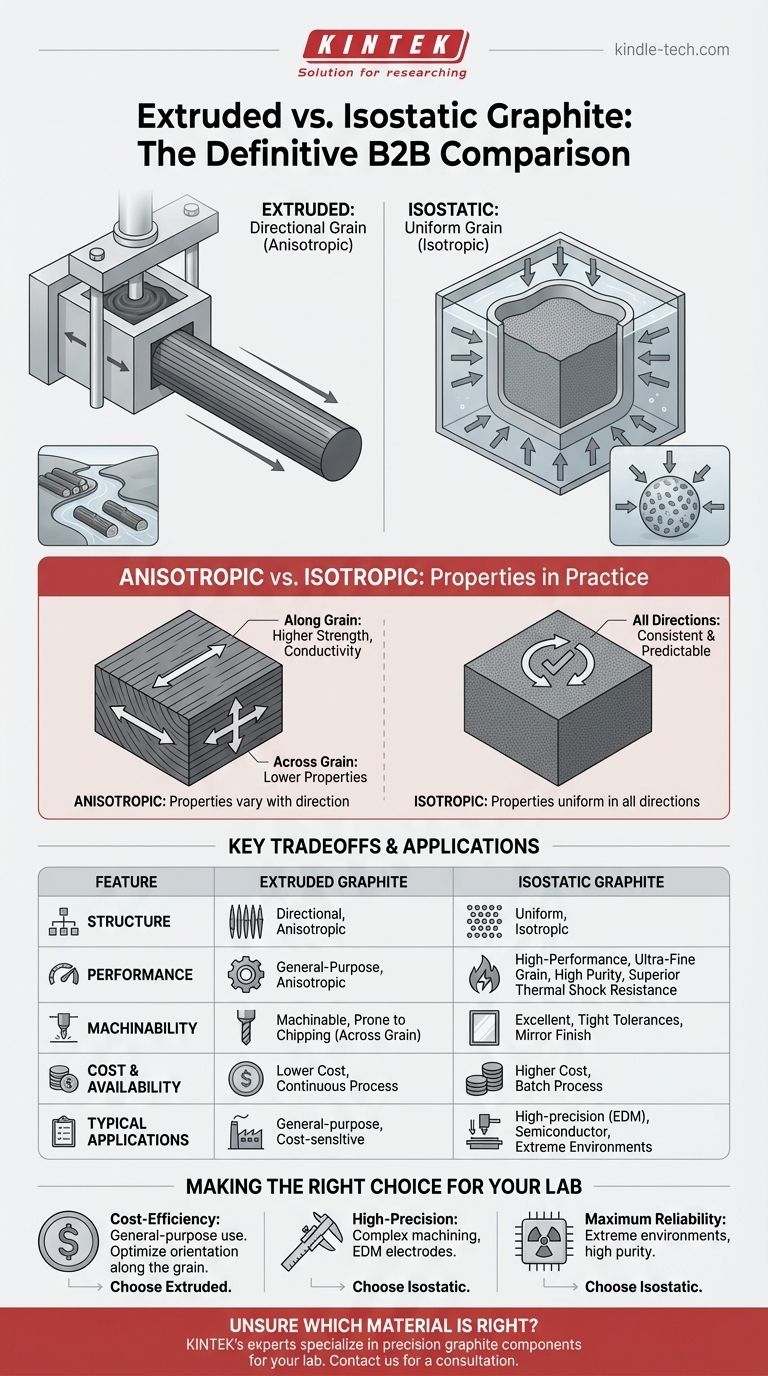

The fundamental difference between extruded and isostatic graphite lies in their manufacturing process, which dictates their internal structure and performance characteristics. Extruded graphite is formed by pushing a raw material mix through a die, creating a directional grain structure. In contrast, isostatic graphite is made by applying equal pressure from all directions, resulting in a uniform, non-directional grain structure with superior properties.

The choice between extruded and isostatic graphite is a classic engineering trade-off. Extruded graphite offers a cost-effective solution for general-purpose applications, while isostatic graphite provides the uniform, high-performance properties required for the most demanding and precise tasks.

The Manufacturing Process: The Root of the Difference

The properties of a graphite block are a direct result of how it was formed. The terms "extruded" and "isostatic" refer to these distinct manufacturing methods.

Extrusion: Creating a Directional Grain

Extrusion involves forcing a paste-like mixture of coke particles and a binder through a die to form rods or blocks.

This process forces the needle-like coke particles to align with the direction of extrusion, much like logs floating down a river. This alignment creates a distinct grain direction within the material.

Isostatic Pressing: Uniform Pressure, Uniform Properties

Isostatic graphite is made using a process called Cold Isostatic Pressing (CIP). A fine-grain powder mix is placed in a flexible mold, which is then submerged in a high-pressure liquid chamber.

Pressure is applied equally from all directions, compacting the powder into a solid block. This prevents the particles from aligning, resulting in a random orientation and an extremely fine, uniform internal structure.

Anisotropic vs. Isotropic: What It Means in Practice

The manufacturing process directly leads to the most important distinction: whether the material's properties are the same in all directions.

The Anisotropic Nature of Extruded Graphite

Because of its aligned grain, extruded graphite is anisotropic. Its properties are different when measured "with the grain" versus "against the grain."

This means its thermal conductivity, electrical conductivity, and mechanical strength are significantly higher along the direction of extrusion. This must be carefully considered during component design and machining.

The Isotropic Advantage of Isostatic Graphite

Isostatic graphite is isotropic, meaning its properties are uniform and consistent regardless of the direction in which they are measured.

This predictability is a massive advantage. A component machined from an isostatic block will have the same strength, conductivity, and resistance to thermal shock no matter its orientation, simplifying design and ensuring reliability.

Understanding the Trade-offs

Choosing between these two materials requires balancing performance needs against budget and application requirements.

Performance and Purity

Isostatic graphite is a premium, high-performance material. It has an ultra-fine grain, which contributes to higher strength, superior thermal shock resistance, and excellent resistance to oxidation. It can also be manufactured to extremely high purity levels (less than 5 ppm of impurities).

Extruded graphite is a more general-purpose material with a larger grain size and lower overall strength and density.

Machinability

The fine grain and uniform structure of isostatic graphite allow it to be machined to incredibly tight tolerances and achieve a mirror-like surface finish. This makes it the ideal choice for applications like EDM electrodes or semiconductor crucibles.

While machinable, extruded graphite is more susceptible to chipping, especially when machining against its grain direction.

Cost and Availability

Extrusion is a simpler, more continuous manufacturing process, making extruded graphite significantly less expensive than its isostatic counterpart. It is also often available in longer stock lengths.

Isostatic pressing is a more complex, batch-oriented process. The higher production cost is reflected in the material's price.

Making the Right Choice for Your Application

Selecting the correct graphite grade is critical for both the performance of your part and the economics of your project.

- If your primary focus is cost-efficiency for general-purpose use: Choose extruded graphite, but ensure you orient your part to take advantage of its properties along the grain.

- If your primary focus is high-precision machining and predictable performance: Choose isostatic graphite for its excellent machinability and uniform properties, especially for applications like EDM.

- If your primary focus is maximum reliability in extreme environments: Choose isostatic graphite for its superior strength, purity, and resistance to thermal shock, as required in semiconductor or nuclear fields.

Ultimately, understanding the fundamental difference between a directional and a uniform material structure empowers you to select the right tool for the job.

Summary Table:

| Feature | Extruded Graphite | Isostatic Graphite |

|---|---|---|

| Manufacturing Process | Pushed through a die | Equal pressure from all directions (CIP) |

| Grain Structure | Directional (Anisotropic) | Uniform (Isotropic) |

| Key Property | Properties vary with direction | Consistent properties in all directions |

| Typical Applications | General-purpose, cost-sensitive | High-precision (EDM), extreme environments (Semiconductor) |

| Relative Cost | Lower | Higher |

Unsure which graphite material is right for your project? KINTEK specializes in high-performance lab equipment and consumables, including precision graphite components. Our experts can help you navigate the trade-offs between extruded and isostatic graphite to ensure optimal performance and cost-efficiency for your specific laboratory needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the purpose of using electrolytic polishing on copper foils? Optimize Your CVD Graphene & hBN Growth Surface

- How long does it take to solder? A guide to timing and technique for perfect joints

- What is the purpose of alumina polishing powder in GCE pretreatment? Master Surface Prep for Electrochemistry

- What is the step-by-step process for polishing, testing, and cleaning an electrode? A Pro Guide for Precision Results

- How does sample size affect analysis? Maximize the Reliability of Your Research