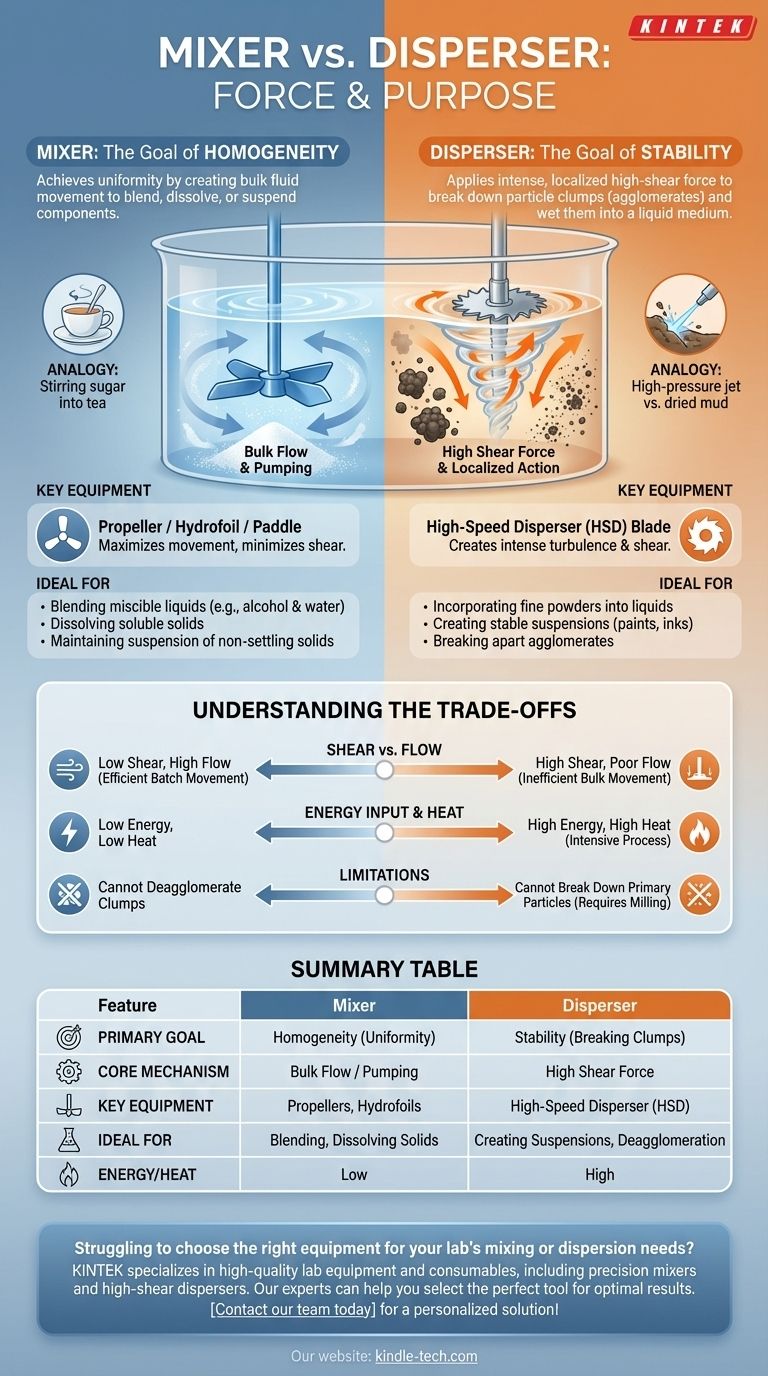

At their core, the difference is one of force and purpose. A mixer is designed to achieve homogeneity by creating bulk fluid movement to blend, dissolve, or suspend components. A disperser, on the other hand, is designed to create stability by applying intense, localized high-shear force to break down particle clumps (agglomerates) and wet them into a liquid medium.

The fundamental distinction is not in the equipment itself, but in the goal of the process. Mixing aims for uniformity through flow, while dispersion aims for a stable, fine particle suspension through high-energy shear. Choosing the wrong tool leads to inefficiency, poor product quality, and wasted energy.

What is Mixing? The Goal of Homogeneity

Mixing is a process focused on achieving a uniform consistency throughout a volume. It addresses the macro-level state of the product, ensuring that all components are evenly distributed.

The Core Principle: Bulk Flow

The primary mechanism of a mixer is bulk flow, also known as pumping. The equipment is designed to move large quantities of material within a vessel, folding and blending the components together.

Think of stirring sugar into tea. The spoon's motion creates currents that distribute the sugar crystals throughout the liquid until they are dissolved and the entire drink is uniformly sweet.

Key Equipment: Impellers and Paddles

Mixers typically use impellers like propellers, hydrofoils, or turbines. These blades are engineered to maximize fluid movement while minimizing shear. Their goal is to efficiently circulate the entire batch volume.

When to Use a Mixer

A mixer is the correct tool for tasks where high shear is unnecessary or even undesirable. Common applications include:

- Blending two or more miscible liquids (e.g., water and alcohol).

- Dissolving soluble solids into a liquid (e.g., salt in water).

- Maintaining the suspension of large, non-settling solids.

What is Dispersion? The Goal of Stability

Dispersion is a high-energy process required when you need to incorporate fine solid particles into a liquid and ensure they don't clump back together or settle out over time. This is critical in products like paints, inks, and many cosmetics.

The Core Principle: High Shear Force

Dispersers work by applying intense shear force in a localized zone. This force attacks and breaks apart agglomerates—collections of primary particles held together by intermolecular forces.

Instead of gentle stirring, imagine using a high-pressure water jet to break apart a stubborn clump of dried mud. The energy is focused and intense, designed to tear things apart at a micro level.

Key Equipment: The High-Speed Disperser (HSD) Blade

The classic tool for dispersion is a high-speed disperser (HSD), often equipped with a sawtooth-style blade (sometimes called a Cowles blade). This blade rotates at very high speeds (tip speeds can reach 5,000 ft/min or ~25 m/s).

It creates a visible vortex that pulls material down from the surface and into a region of intense turbulence and shear at the blade tips. It's in this zone that the deagglomeration happens.

The Three Stages of Dispersion

Achieving a good dispersion is a multi-step process:

- Particle Wetting: The liquid vehicle must first displace the air on the surface of the powder particles.

- Deagglomeration: Mechanical energy from the HSD blade is applied to break apart the agglomerates into smaller groups or primary particles.

- Stabilization: Chemical additives (surfactants or dispersants) are used to coat the newly exposed particle surfaces, preventing them from re-clumping (flocculation).

Understanding the Trade-offs

Choosing between a mixer and a disperser involves clear engineering trade-offs. Misunderstanding them is the most common source of processing failure.

Shear vs. Flow

This is the central compromise. Mixers excel at flow but provide low shear. They are highly efficient at moving the entire batch. Dispersers provide extremely high shear but are poor at bulk flow. An HSD blade is inefficient at mixing the contents of a large tank on its own.

Energy Input and Heat

Dispersion is an energy-intensive process. The high tip speeds of an HSD impart significant mechanical energy into the product, which is converted into heat. This can be a major issue for temperature-sensitive materials. Mixing is a far lower-energy and lower-heat operation.

When a Disperser Isn't Enough: Milling

It's critical to know that a disperser breaks apart agglomerates (clumps of particles). It does not have enough energy to break down the primary particles themselves. If you need to reduce the size of the primary particles, you must move to a more intensive process like media milling.

Selecting the Right Tool for Your Application

To make the correct choice, you must first define your desired end state.

- If your primary focus is blending liquids or dissolving soluble solids: A low-speed mixer is the correct, most energy-efficient choice.

- If your primary focus is incorporating powders into a liquid to create a stable, fine suspension: A high-speed disperser is essential to provide the shear needed for deagglomeration.

- If you are working with a high-viscosity product or need both flow and shear: You may require a multi-shaft vessel that combines a low-speed anchor for bulk movement and a high-speed disperser for shear.

Choosing the right equipment begins with a clear understanding of your end goal: simple uniformity or a stable, deagglomerated particle system.

Summary Table:

| Feature | Mixer | Disperser |

|---|---|---|

| Primary Goal | Homogeneity (uniform blending) | Stability (breaking particle clumps) |

| Core Mechanism | Bulk Flow / Pumping | High Shear Force |

| Key Equipment | Propellers, Hydrofoils | High-Speed Disperser (HSD) Blade |

| Ideal For | Blending liquids, dissolving solids | Creating stable suspensions (paints, inks) |

| Energy/Heat | Low | High |

Struggling to choose the right equipment for your lab's mixing or dispersion needs? KINTEK specializes in high-quality lab equipment and consumables, including precision mixers and high-shear dispersers. Our experts can help you select the perfect tool to achieve optimal homogeneity or particle stability, ensuring efficiency and superior product quality. Contact our team today to discuss your specific application and get a personalized solution!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Single Horizontal Jar Mill

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the mechanism of action of a colloid mill? Master High-Shear Processing for Superior Emulsions and Dispersions

- Why is grinding important in sample preparation? Ensure Accurate & Reliable Analytical Results

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What is a laboratory mixer? A Guide to Achieving Perfect Sample Homogeneity

- What is the purpose of a mixer? Achieve Perfect Baking Results with Less Effort