At their core, Vacuum Arc Remelting (VAR) and Electroslag Remelting (ESR) are both secondary melting processes designed to refine steel, but they achieve this through fundamentally different mechanisms. VAR uses a high vacuum to pull out dissolved gases and volatile impurities, while ESR uses a molten slag bath to chemically scrub the steel of non-metallic inclusions. The result is two distinct types of high-purity steel, each optimized for different critical applications.

The choice between VAR and ESR is not about which process is universally superior, but which one best mitigates the most likely failure mode for your component. VAR excels at removing gases to improve fatigue life, whereas ESR is unmatched at removing inclusions to enhance toughness and cleanliness.

The Foundation: Why Remelt Steel?

All high-performance steels begin with a primary melting process, often in an Electric Arc Furnace (EAF). However, this initial melt contains imperfections that are unacceptable for critical applications.

The Limits of Primary Melting

Primary melting leaves behind undesirable elements. These include dissolved gases like hydrogen and nitrogen, which can cause voids, and non-metallic inclusions like oxides and sulfides, which act as stress risers and initiation points for cracks.

The Goal of Secondary Refining

Secondary remelting processes like VAR and ESR take the solid steel electrode from the primary melt and re-melt it in a controlled environment. The goal is to purify and homogenize the steel, creating a final ingot with a refined structure and far fewer defects.

Deconstructing the VAR Process

Vacuum Arc Remelting is fundamentally a purification process that leverages the physics of a vacuum.

How VAR Works

In the VAR process, a solid steel electrode (the "consumable electrode") is suspended in a water-cooled copper crucible under a high vacuum. An electric arc is struck between the electrode and the base of the crucible, causing the electrode tip to melt and drip down, solidifying progressively from the bottom up.

The Power of the Vacuum

The high vacuum environment is the key to VAR's effectiveness. It aggressively pulls dissolved gases—most notably hydrogen, nitrogen, and oxygen—out of the molten metal before it can solidify. It also vaporizes and removes trace elements with high vapor pressures, like lead, antimony, and bismuth.

Resulting Material Properties

VAR produces steel with extremely low gas content. This significantly improves properties sensitive to internal voids and microporosity, leading to superior fatigue strength and ductility. This makes it a standard for rotating parts in aerospace and power generation.

Deconstructing the ESR Process

Electroslag Remelting is a chemical refining process that uses a special slag as a reactive filter.

How ESR Works

In ESR, the consumable electrode is lowered into a pool of highly engineered, molten slag. An electric current passes through the electrode, into the slag, and to the base of the water-cooled mold. The electrical resistance of the slag generates intense heat, melting the tip of the electrode.

The Role of the Reactive Slag

As droplets of molten steel detach from the electrode, they must pass through the superheated slag bath. This slag is specifically designed to act like a chemical sponge, absorbing non-metallic inclusions such as oxides and sulfides from the steel droplets.

Resulting Material Properties

ESR produces exceptionally clean steel with a very low volume of inclusions. This cleanliness dramatically improves the material's toughness, impact strength, and transverse properties (properties measured perpendicular to the grain flow). It also typically results in an ingot with a better surface finish, increasing material yield.

Understanding the Trade-offs

Choosing between VAR and ESR requires acknowledging that the term "clean steel" can be ambiguous and that both processes have specific strengths and limitations.

Gas Removal vs. Inclusion Removal

This is the central trade-off.

- VAR is superior for removing dissolved gases. The vacuum is simply more effective at this than ESR's slag blanket.

- ESR is superior for removing non-metallic inclusions. The reactive slag provides a chemical filtration that the vacuum of VAR cannot replicate.

Ingot Structure and Yield

ESR generally produces an ingot with a better surface finish, requiring less machining and leading to a higher final yield. The solidification in a VAR furnace can sometimes be less uniform, leading to a rougher ingot surface.

Cost and Application Specificity

Both VAR and ESR are premium processes that add significant cost compared to conventional air-melted steel. The decision to use one is an engineering choice to invest in material properties that directly prevent a known failure mode, such as fatigue in an aircraft engine or fracture in a large industrial die.

Making the Right Choice for Your Application

Your material specification should be driven by the demands of the component's service environment.

- If your primary focus is maximum fatigue life and performance under cyclic loading (e.g., aerospace bearings, turbine discs, connecting rods): VAR is the superior choice because removing dissolved gases prevents the formation of microporosity that initiates fatigue cracks.

- If your primary focus is maximum toughness, impact strength, and polishability (e.g., large forging dies, high-performance plastic injection molds): ESR is the preferred process due to its unparalleled ability to remove the non-metallic inclusions that initiate fractures.

- If you require the absolute highest level of purity for the most demanding applications: A "triple-melt" process (often VIM -> ESR -> VAR) can be used to leverage the benefits of both, first using ESR to remove inclusions and then VAR to remove gases.

By understanding the distinct refining mechanisms of VAR and ESR, you can specify a material precisely engineered to resist its most likely mode of failure.

Summary Table:

| Process | Primary Mechanism | Key Benefit | Ideal For |

|---|---|---|---|

| VAR (Vacuum Arc Remelting) | High Vacuum | Removes dissolved gases (H₂, N₂, O₂) | Superior fatigue strength (e.g., aerospace bearings, turbine discs) |

| ESR (Electroslag Remelting) | Molten Slag Bath | Removes non-metallic inclusions (oxides, sulfides) | Superior toughness & impact strength (e.g., forging dies, molds) |

Need high-purity steel for your critical application?

The choice between VAR and ESR is crucial for performance and longevity. At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to support the development and quality control of these high-performance materials. Our solutions help metallurgists and engineers ensure their steel meets the strictest standards for purity and reliability.

Let KINTEK be your partner in precision. We can help you select the right tools for your specific needs. Contact our experts today to discuss how we can support your laboratory's mission.

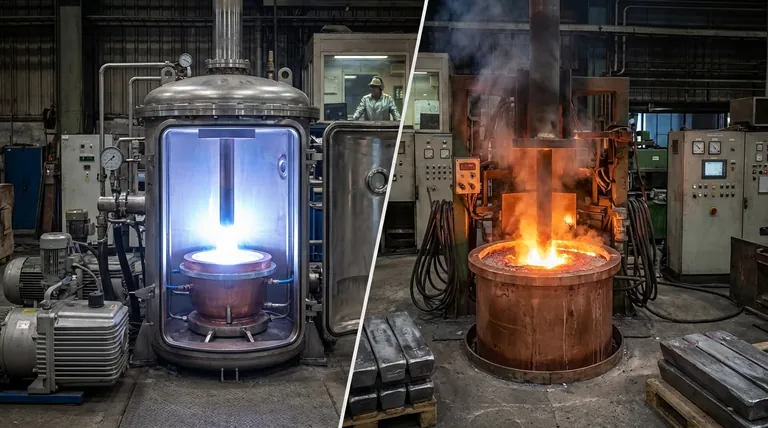

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is VAR in metallurgy? Achieve Superior Metal Purity and Performance

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What is the overview of vacuum arc remelting? Achieve Ultra-Clean, High-Performance Alloys

- What is the process of vacuum arc remelting? Achieve Ultimate Purity for High-Performance Alloys