A filter press does not have a single, fixed flow rate. Instead, its performance is a dynamic variable that declines throughout the filtration cycle. The flow rate is highest at the very beginning of a cycle when the press is empty and resistance is low, and it drops to nearly zero by the end as the chambers fill with solid cake and resistance becomes extremely high.

The central takeaway is to stop thinking about a single "flow rate" and instead view filter press performance as a dynamic cycle. The key to optimization is not maximizing a single number, but understanding and balancing the variables that control the entire process from initial filling to final cake formation.

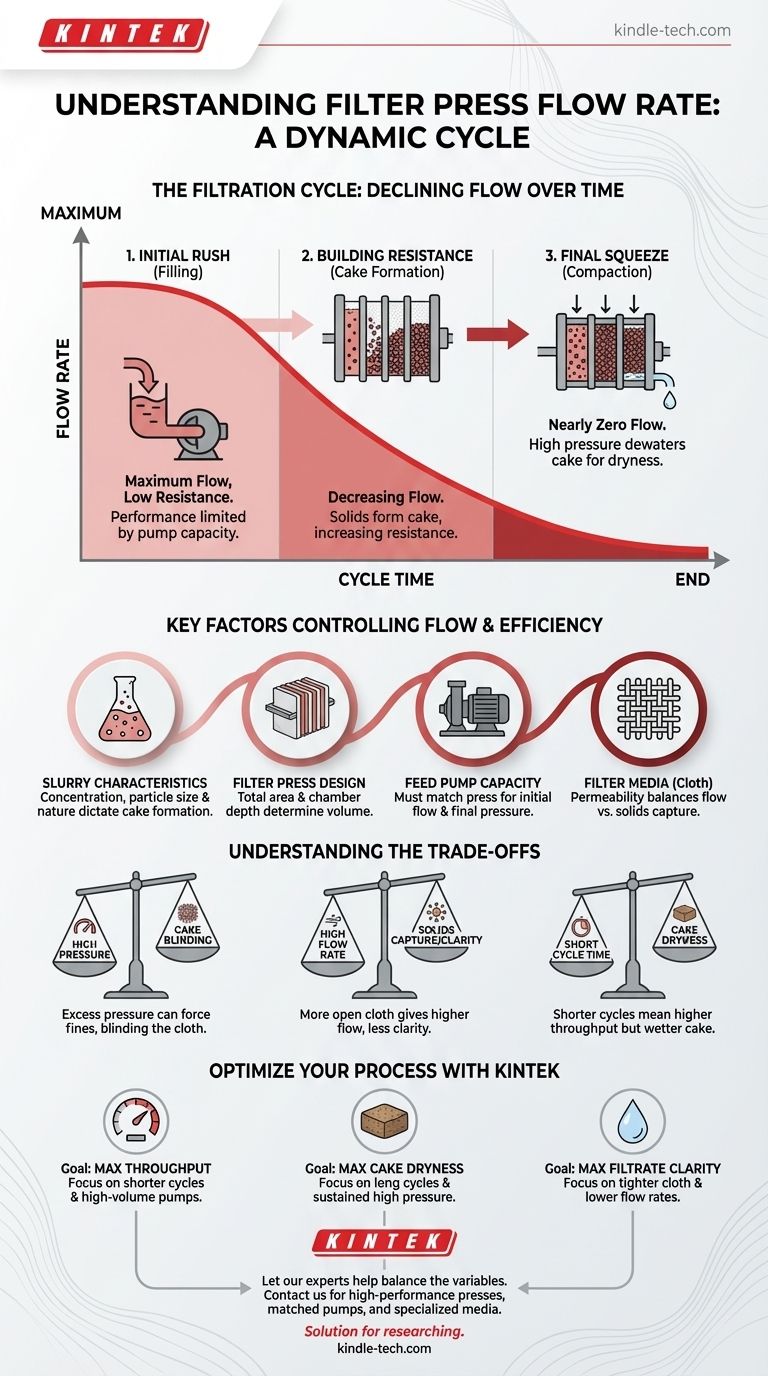

The Filtration Cycle: A Story of Declining Flow

The flow of liquid (filtrate) out of a press is not constant. It follows a predictable curve that is directly related to the formation of the solid "cake" inside the press chambers.

Phase 1: The Initial Rush (Filling)

At the start of the cycle, the feed pump pushes slurry into empty chambers. With only the filter cloth providing resistance, the flow rate of the filtrate is at its maximum. At this stage, performance is primarily limited by the capacity of your feed pump.

Phase 2: Building Resistance (Cake Formation)

As solids begin to deposit on the filter cloth, they form an initial layer. This layer, the filter cake, becomes the primary filtering medium. As the cake thickens, the resistance to flow increases significantly, causing the flow rate to steadily decrease.

Phase 3: The Final Squeeze (Compaction)

Eventually, the chambers become packed with solid cake. The flow of filtrate slows to a trickle and then stops completely. At this point, the pump's energy is no longer moving liquid but is instead applying high pressure to compact and dewater the cake, achieving the desired final dryness.

Key Factors Controlling Flow and Efficiency

Several interconnected variables determine the shape of the flow rate curve and the overall efficiency of a cycle.

Slurry Characteristics

This is the most critical factor. The concentration of solids is paramount; a dilute slurry will have a longer period of high flow than a thick one. The size, shape, and nature of the solid particles also dictate how quickly they form a dense, impermeable cake.

Filter Press Design

The total filtration area (determined by the size and number of filter plates) is a direct multiplier of performance. A larger press offers more surface area, allowing for a higher total flow, all other factors being equal. The chamber depth determines the volume of cake that can be formed.

Feed Pump Capacity

The pump is the engine of the system. A pump's ability to deliver both high initial flow and high final pressure is crucial. The pump must be matched to the press and the slurry to avoid issues.

Filter Media (Cloth)

The permeability of the filter cloth acts as the gatekeeper. A more "open" weave allows for higher initial flow but may let very fine particles pass through. A "tighter" weave provides clearer filtrate from the start but at the cost of a lower initial flow rate.

Understanding the Trade-offs

Optimizing a filter press is always an exercise in balancing competing goals. A change made to improve one metric often impacts another.

High Pressure vs. Cake Blinding

Using excessively high pressure at the start of a cycle can seem like a way to force a high flow rate. However, this can drive fine particles deep into the filter cloth, "blinding" it and creating a dense, low-permeability cake layer that severely restricts flow for the rest of the cycle.

Flow Rate vs. Solids Capture

A highly permeable filter cloth will yield a very high initial flow rate. The trade-off is often filtrate clarity. If capturing the finest solids is the goal, a tighter cloth and a slower flow rate are necessary.

Cycle Time vs. Cake Dryness

You can achieve a high average throughput (gallons of slurry processed per hour) by running very short cycles. However, this means you are stopping the process before the cake is fully compacted, resulting in a much wetter, heavier cake that is more costly to handle and dispose of.

Making the Right Choice for Your Goal

The "ideal" flow rate is the one that results from a cycle optimized for your specific operational priority.

- If your primary focus is maximum throughput (processing the most slurry): Optimize for shorter cycle times, accepting a wetter cake, and ensure your pump can deliver high volume.

- If your primary focus is maximum cake dryness: Optimize for a longer cycle with a sustained high-pressure squeeze at the end; the initial flow rate is less critical than the final compaction phase.

- If your primary focus is filtrate clarity: Select a tighter filter cloth and potentially use a pre-coat; accept that a lower flow rate is the necessary trade-off for achieving purity.

By understanding these principles, you can strategically control the variables that deliver the precise results your operation requires.

Summary Table:

| Cycle Phase | Flow Rate | Key Action |

|---|---|---|

| Initial Filling | Maximum | Pump fills empty chambers |

| Cake Formation | Steadily Decreasing | Solids build up, increasing resistance |

| Final Compaction | Nearly Zero | High pressure dewaters the cake |

Optimize Your Filtration Process with KINTEK

Understanding the dynamic nature of your filter press's flow rate is the first step to maximizing efficiency. Whether your priority is maximum throughput, driest cake, or clearest filtrate, the right equipment and consumables are critical.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide the high-performance filter presses, matched pumps, and specialized filter cloths you need to precisely control your filtration cycle and achieve your specific goals.

Let our experts help you balance the variables for optimal results. Contact us today to discuss your application and discover the KINTEK solution for you.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the purpose of a mixer? Achieve Perfect Baking Results with Less Effort

- Do cannabinoids evaporate? How to Preserve Potency and Prevent Degradation

- What type of wastes are used for the pyrolysis treatment? Unlock Value from Organic Waste Streams

- What tool can break diamond? Understanding the Science and Techniques

- How does a gold sputter coater work? A Step-by-Step Guide to Creating Conductive Coatings

- What is high temperature method? A Guide to Controlled Thermal Transformation

- How does hardness change with temperature? Understand the Inverse Relationship to Prevent Failure

- What is the sample KBr ratio for FTIR? Master the 1:100 Ratio for Perfect Pellet Preparation