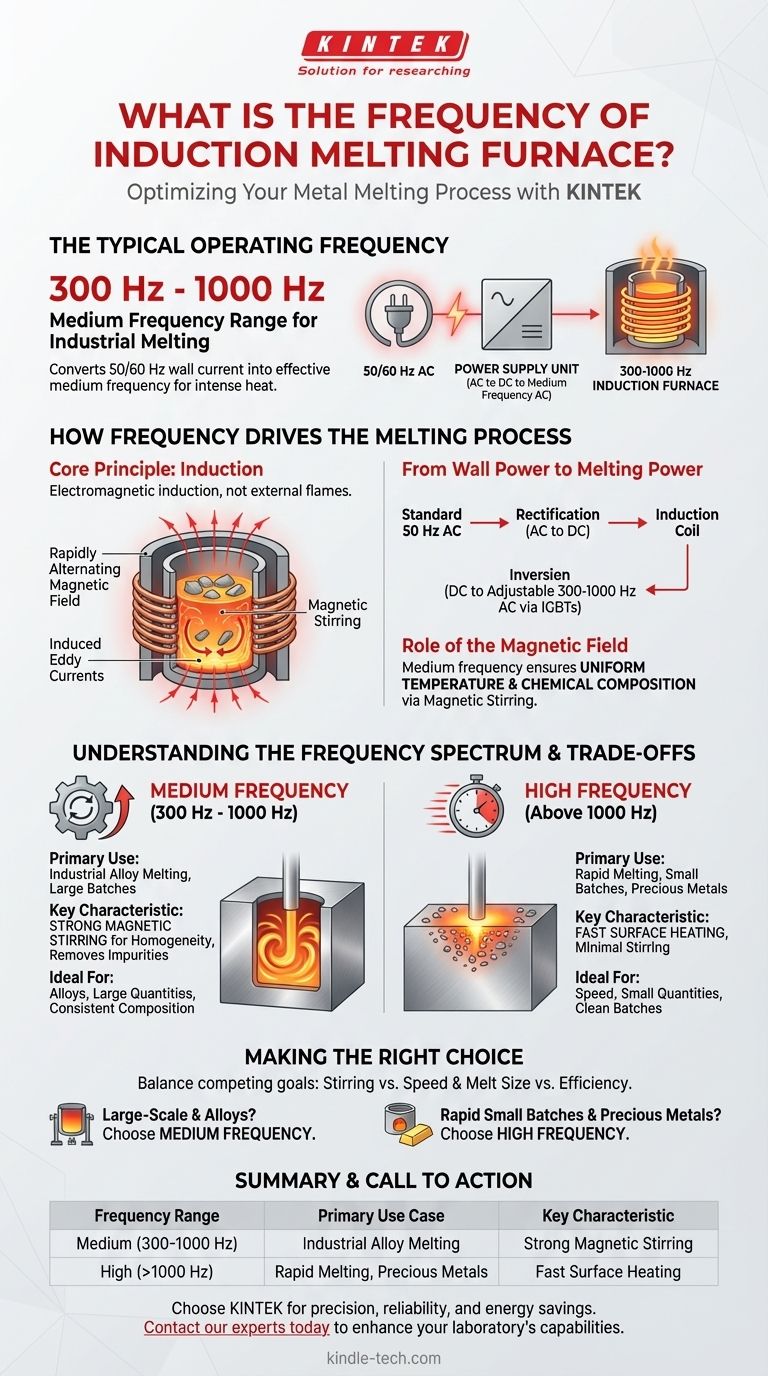

The typical operating frequency of an induction melting furnace falls into the medium frequency range of 300 Hz to 1000 Hz. This specialized frequency is generated by a power supply unit that converts the standard 50/60 Hz wall current into a more effective current for generating the intense heat required for melting metals.

The choice of operating frequency is a critical design decision that dictates the furnace's primary function. Lower (medium) frequencies create a strong stirring effect ideal for large, uniform melts, while higher frequencies are more efficient for rapidly melting smaller quantities of metal.

How Frequency Drives the Melting Process

To understand the significance of the 300-1000 Hz range, it's essential to understand the core principle of induction heating and how the furnace's power supply achieves this specific frequency.

The Core Principle: Induction

An induction furnace does not use an external flame or heating element. Instead, it relies on the principle of electromagnetic induction.

A high current flows through a copper coil, creating a powerful, rapidly alternating magnetic field inside the furnace. This magnetic field induces powerful eddy currents within the metal placed inside, causing it to heat up and melt from the inside out.

From Wall Power to Melting Power

The process begins with standard three-phase alternating current (AC) at a power frequency of 50 Hz.

A power supply device first converts this AC into direct current (DC). Then, using advanced solid-state components like IGBTs, it converts the DC back into an adjustable, single-phase AC at a much higher medium frequency (300-1000 Hz).

The Role of the Magnetic Field

This medium-frequency current is what energizes the induction coil. The frequency is critical because it dictates the behavior of the magnetic field.

At these frequencies, the magnetic field creates a magnetic stirring effect. This agitation naturally mixes the molten metal, ensuring a uniform temperature and chemical composition throughout the melt, which is vital for creating high-quality alloys.

Understanding the Frequency Spectrum

While medium frequency is common, it is not the only option. The choice of frequency is directly tied to the intended application of the furnace.

Medium Frequency (300 Hz - 1000 Hz)

This is the workhorse range for most industrial melting applications. Its primary advantage is the excellent stirring action, which promotes homogeneity and helps remove impurities (scum).

These furnaces are ideal for producing alloys and melting larger batches of metal where consistent composition is paramount.

High Frequency (Above 1000 Hz)

High-frequency furnaces are designed for different tasks. They induce heat very rapidly in the surface layers of the metal.

This makes them extremely efficient for melting small quantities of metal very quickly, often in just a few minutes. They are commonly used for precious metals like gold and silver or in laboratory settings where speed is essential and less magnetic stirring is required.

Understanding the Trade-offs

Choosing a furnace frequency involves balancing competing engineering goals. There is no single "best" frequency; there is only the best frequency for a specific task.

Stirring vs. Speed

The most significant trade-off is between mixing and melting speed.

Medium frequency provides robust stirring, which is crucial for alloying, but may be slower to melt the initial charge. High frequency offers incredibly fast melting but with minimal stirring, making it less suitable for creating homogenous alloys from different starting metals.

Melt Size and Efficiency

The frequency must be matched to the size of the material being melted for maximum efficiency.

A medium frequency magnetic field penetrates deeper into the metal charge, making it effective for large billets or significant quantities of scrap. A high-frequency field has a shallower penetration, making it ideal for rapidly heating smaller pieces or powders.

Equipment and Application

The power supply technology (like the IGBT modules mentioned in the references) enables precise control over the frequency and power.

This allows for furnaces that are not only powerful but also compact, energy-saving, and capable of 24-hour continuous operation. The choice directly impacts the furnace's size, cost, and overall performance characteristics.

Making the Right Choice for Your Application

The optimal frequency is determined entirely by your melting requirements. Consider the material, batch size, and desired outcome to select the appropriate technology.

- If your primary focus is large-scale melting and creating alloys: A medium-frequency furnace is the correct choice for its powerful stirring action and ability to ensure a uniform final product.

- If your primary focus is rapidly melting small, clean batches or precious metals: A high-frequency furnace offers superior speed and efficiency for these specific applications.

Ultimately, the furnace's frequency is tuned to the specific task, balancing the need for uniform mixing with the demand for rapid, efficient heating.

Summary Table:

| Frequency Range | Primary Use Case | Key Characteristic |

|---|---|---|

| Medium (300-1000 Hz) | Industrial alloy melting, large batches | Strong magnetic stirring for uniform composition |

| High (>1000 Hz) | Rapid melting of small batches, precious metals | Fast surface heating, minimal stirring |

Optimize your metal melting process with KINTEK!

Choosing the right induction furnace frequency is critical for achieving the perfect melt quality, efficiency, and cost-effectiveness for your specific application—whether you're working with large-scale industrial alloys or small batches of precious metals.

As a specialist in lab equipment and consumables, KINTEK provides the expertise and technology to match you with the ideal induction melting solution. Our furnaces are designed for precision, reliability, and energy savings.

Contact our experts today to discuss your requirements and discover how KINTEK's induction melting furnaces can enhance your laboratory's capabilities and productivity.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys