At its core, the heat treatment of steel is a highly controlled process of heating and cooling the metal to deliberately alter its internal structure. This is not a single method, but a family of techniques designed to manipulate steel's physical and mechanical properties. The goal is to achieve specific characteristics, such as increased hardness, improved toughness, or enhanced machinability, without changing the steel's shape.

The central purpose of heat treating steel is to modify its microstructure—the internal arrangement of its crystals. By controlling the temperature and the rate of cooling, you can dictate whether the final steel is hard and brittle, soft and ductile, or a precisely engineered combination of both.

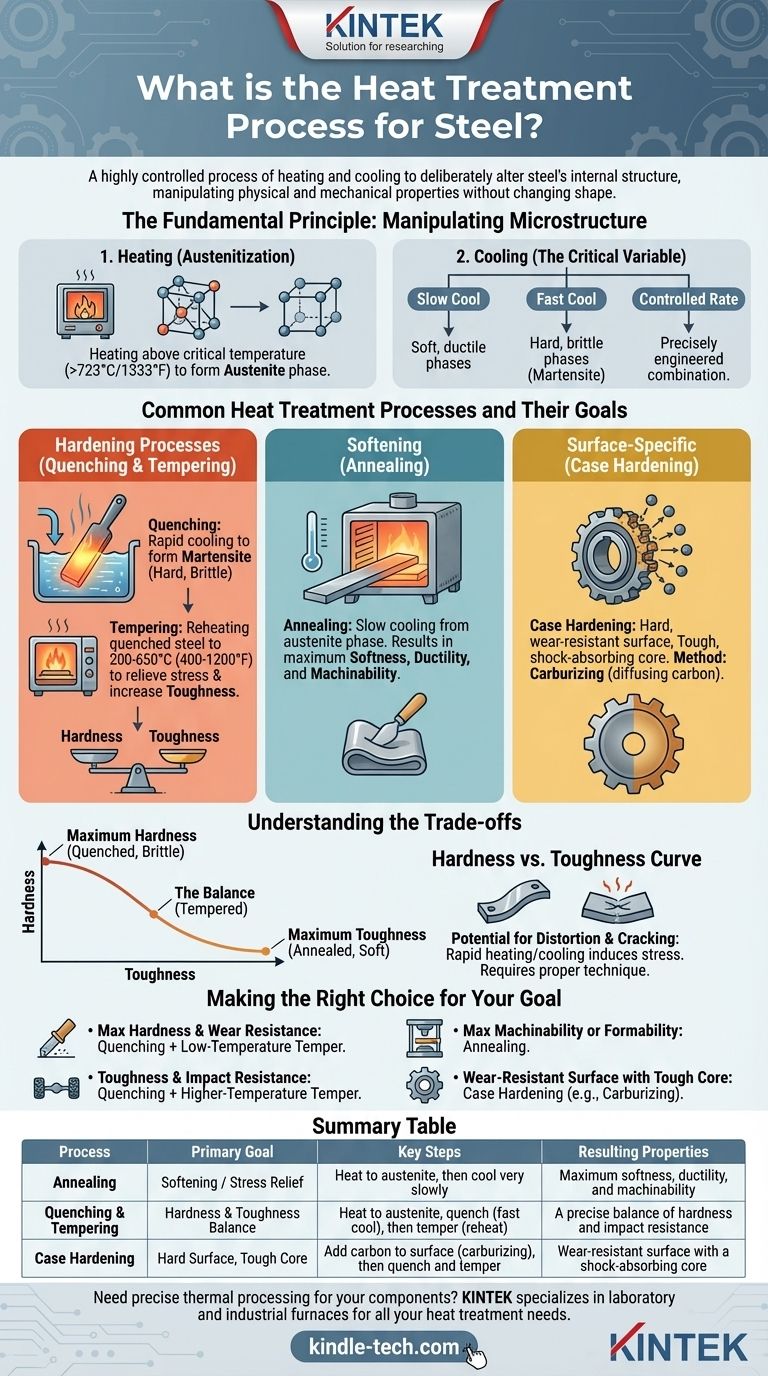

The Fundamental Principle: Manipulating Microstructure

To understand heat treatment, you must first understand that steel is not a static material. Its properties are dictated by its internal crystalline structure, which can be changed with heat.

The Role of Heating (Austenitization)

When you heat steel above a critical temperature (typically above 723°C or 1333°F), its crystal structure transforms into a phase called austenite.

In this state, the iron lattice can dissolve carbon atoms much more effectively. This austenitic phase is the necessary starting point for most hardening and softening treatments.

The Critical Role of Cooling

The final properties of the steel are determined by what happens as it cools down from the austenite phase. The rate of cooling is the most important variable.

A very slow cool allows the structure to transform into soft, ductile phases. A very fast cool traps the carbon atoms in a new, highly strained structure, creating extreme hardness.

Common Heat Treatment Processes and Their Goals

Different engineering needs require different properties. The following processes are the primary tools used to achieve them.

Hardening Processes: Quenching and Tempering

Quenching is the process of cooling the steel extremely rapidly, typically by plunging it into water, oil, or brine. This rapid cooling freezes the microstructure into a very hard, brittle state called martensite.

While extremely hard, freshly quenched steel is often too brittle for practical use. This is why tempering is an essential follow-up step.

Tempering involves reheating the quenched steel to a lower temperature (e.g., 200-650°C or 400-1200°F) and holding it there. This process relieves internal stresses and trades some of the extreme hardness for a significant increase in toughness, which is the ability to absorb impact without fracturing.

Softening and Stress-Relieving: Annealing

Annealing is essentially the opposite of hardening. The steel is heated to its austenitic phase and then cooled very slowly, often by letting it cool inside the furnace.

This slow cooling allows the microstructure to form into its softest, most ductile state. Annealed steel is easy to machine, form, or stamp, making it ideal for manufacturing processes that occur before a final hardening step.

Surface-Specific Processes: Case Hardening

For many components like gears or bearings, you need a very hard, wear-resistant surface but a softer, tougher core that can withstand shock. Case hardening achieves this.

The most common method is carburizing, where carbon is diffused into the surface of a low-carbon steel part at high temperature.

After carburizing, the part is quenched and tempered. Only the high-carbon "case" becomes extremely hard, while the low-carbon core remains tough and ductile.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a process of balancing competing properties. Making a steel harder almost always makes it more brittle.

The Hardness vs. Toughness Curve

This is the most critical trade-off in metallurgy.

- Maximum Hardness: Achieved by quenching, but results in high brittleness. Ideal for tools that need to hold a sharp edge but won't see high impact.

- Maximum Toughness: Achieved by annealing or high-temperature tempering, but results in a soft material. Ideal for parts that need to deform without breaking.

- The Balance: Most engineering applications require a balance. Tempering allows you to precisely dial in the desired combination of hardness and toughness for a specific application.

Potential for Distortion and Cracking

The rapid heating and cooling cycles, especially quenching, induce significant internal stress in the steel.

If not performed correctly, this stress can cause the part to warp, distort, or even crack. Proper technique, material selection, and part geometry are all critical to avoiding these failures.

Making the Right Choice for Your Goal

The correct heat treatment process is always dictated by the final application of the component.

- If your primary focus is maximum hardness and wear resistance: Specify quenching followed by a low-temperature temper (e.g., for cutting tools or bearings).

- If your primary focus is toughness and impact resistance: Specify quenching followed by a higher-temperature temper (e.g., for vehicle axles, structural bolts, or springs).

- If your primary focus is maximum machinability or formability: Specify annealing as a preliminary step before any shaping operations.

- If your primary focus is a wear-resistant surface with a tough core: Specify a case hardening process like carburizing (e.g., for gears or camshafts).

By understanding these core processes, you can transform a standard piece of steel into a component precisely engineered for its task.

Summary Table:

| Process | Primary Goal | Key Steps | Resulting Properties |

|---|---|---|---|

| Annealing | Softening / Stress Relief | Heat to austenite, then cool very slowly | Maximum softness, ductility, and machinability |

| Quenching & Tempering | Hardness & Toughness Balance | Heat to austenite, quench (fast cool), then temper (reheat) | A precise balance of hardness and impact resistance |

| Case Hardening | Hard Surface, Tough Core | Add carbon to surface (carburizing), then quench and temper | Wear-resistant surface with a shock-absorbing core |

Need precise thermal processing for your components?

Understanding the theory is the first step. Achieving consistent, high-quality results requires the right equipment. KINTEK specializes in laboratory and industrial furnaces for all your heat treatment needs, from precise tempering ovens to high-temperature hardening furnaces.

We provide the reliable thermal processing solutions that manufacturers and R&D labs depend on to achieve exact material properties. Let's discuss how our equipment can enhance your process.

Contact our thermal experts today for a consultation tailored to your application.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature muffle furnace play during 500°C annealing? Ensure Nanopowder Purity and Integrity

- What is the specific application of a high-temperature muffle furnace in the determination of cassava stem biochemical components?

- What is the porosity of sintered ceramics? A Guide to Engineering Material Properties

- What does debinding do? Unlock the Key to Successful Metal and Ceramic Part Manufacturing

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- What is the purpose of using a high-temperature muffle furnace when evaluating the oxidation resistance of Carbon-Carbon composite materials?

- Why are high-precision muffle/tube furnaces required for Deep Cryogenic Treatment? Unlock Peak Material Performance

- What is the function of muffle furnace in food industry? Ensure Accurate Ash Determination for Quality Control