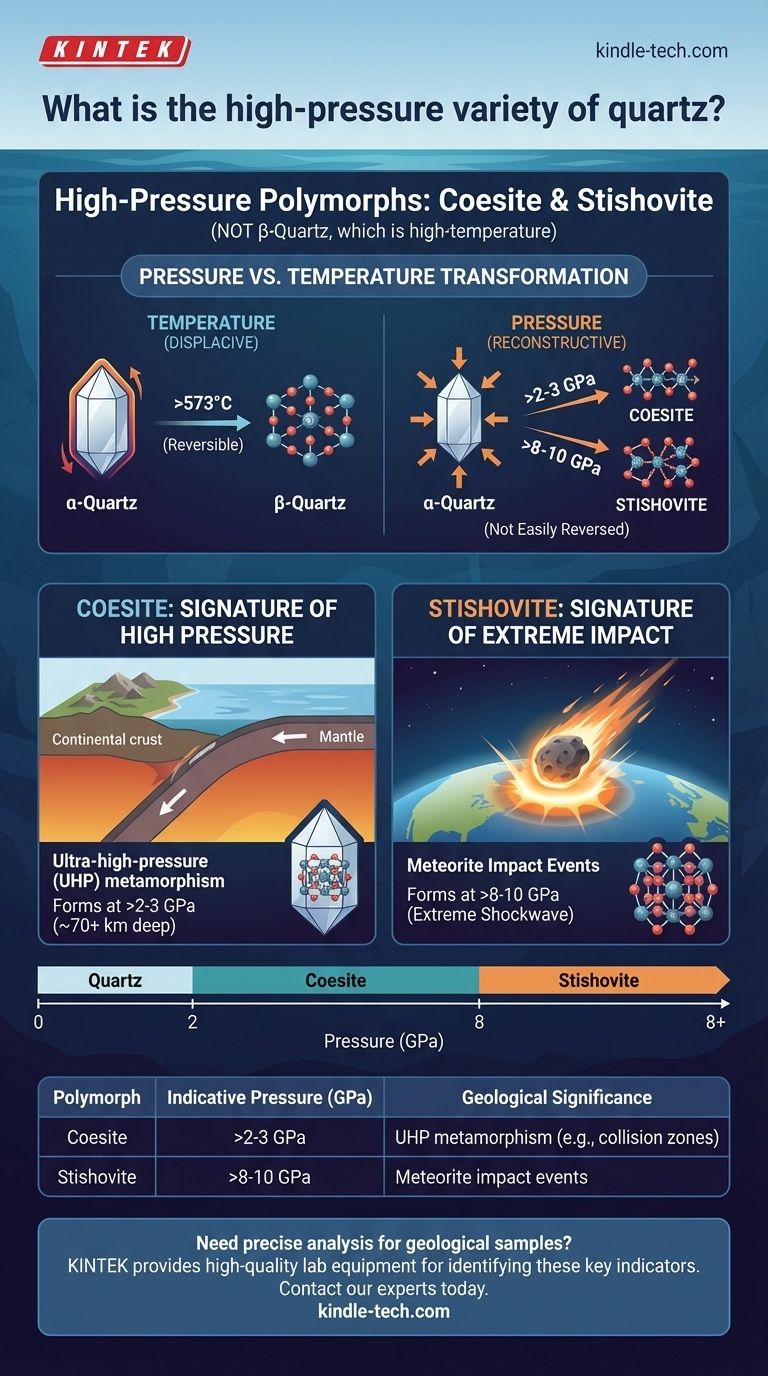

In short, the primary high-pressure polymorphs of quartz (SiO₂) are Coesite and Stishovite. It is a common point of confusion, but "high quartz" or β-quartz is a high-temperature form, not a high-pressure one. Both pressure and temperature independently force the silicon dioxide molecule into different crystal structures.

The form quartz takes is not static; it is a direct reflection of the pressure and temperature conditions under which it formed. Understanding these different forms, or polymorphs, allows us to decipher the history of rocks from deep within the Earth or from meteorite impacts.

Differentiating Pressure vs. Temperature Effects

The most critical concept to grasp is that pressure and temperature are two separate forces that cause different transformations in the SiO₂ crystal lattice.

The Temperature Transformation: α-Quartz and β-Quartz

The term "high quartz" refers to β-quartz (beta-quartz), a polymorph that forms from common α-quartz (alpha-quartz) at temperatures above 573° C at surface pressure.

This is a displacive transformation. The overall crystal structure remains, but the atoms shift their positions slightly. This change is reversible; as β-quartz cools, it immediately reverts back to α-quartz.

The Pressure Transformation: Coesite and Stishovite

Applying immense pressure forces a much more dramatic change. It causes a reconstructive transformation, where atomic bonds are broken and reformed into a denser, more compact structure.

These changes require enormous pressure and are not easily reversed, effectively locking a record of that pressure into the mineral.

The True High-Pressure Polymorphs

When geologists find Coesite or Stishovite, they know the rock has experienced extreme conditions not found at the Earth's surface.

Coesite: The Signature of High Pressure

Coesite forms at pressures above 2-3 gigapascals (GPa), equivalent to the pressure found at depths of over 70 km in the Earth's crust.

Its structure is significantly denser than quartz. The presence of coesite is a key indicator of ultra-high-pressure (UHP) metamorphism, often associated with continental collision zones where crustal material is subducted deep into the mantle.

Stishovite: The Signature of Extreme Impact

At even more extreme pressures, typically above 8-10 GPa, Stishovite is formed. These conditions are rarely achieved through tectonic processes on Earth.

Stishovite is an exceptionally dense polymorph where each silicon atom is bonded to six oxygen atoms instead of the usual four. Its presence is considered definitive proof of a meteorite impact, as the shockwave from an impact is one of the few natural events capable of generating such immense pressure.

Understanding the Geological Significance

The existence of these polymorphs is not just a scientific curiosity; it is a fundamental tool for interpreting a rock's history. They serve as reliable geological pressure gauges.

Minerals as Geobarometers

Because each polymorph is stable only within a specific pressure-temperature range, finding one of them tells a geologist the minimum pressure the host rock must have endured.

This allows for the reconstruction of powerful geological events from the past, turning a simple mineral into a story of mountain-building or extraterrestrial impact.

Indicators of Geodynamic Processes

The discovery of coesite fundamentally changed our understanding of plate tectonics, proving that continental crust could be subducted to great depths and then return to the surface.

Similarly, stishovite found at sites like Meteor Crater in Arizona provides undeniable evidence of an impact event, settling debates about the origin of such features.

Applying This Knowledge

Your interpretation of these minerals depends on your goal.

- If your primary focus is mineralogy: Your key takeaway is that quartz is just one member of the SiO₂ polymorph family, with Coesite and Stishovite representing its high-pressure forms.

- If your primary focus is geology or petrology: Your key takeaway is that Coesite and Stishovite are powerful diagnostic tools that serve as definitive indicators of ultra-high-pressure metamorphism and meteorite impacts, respectively.

Ultimately, a single chemical formula, SiO₂, tells a profound story about the immense forces that shape our planet.

Summary Table:

| Polymorph | Indicative Pressure (GPa) | Geological Significance |

|---|---|---|

| Coesite | > 2-3 GPa | Ultra-high-pressure metamorphism (e.g., continental collision) |

| Stishovite | > 8-10 GPa | Meteorite impact events |

Need precise analysis for geological samples?

Understanding mineral polymorphs like Coesite and Stishovite is crucial for accurate geological interpretation. KINTEK specializes in supplying high-quality lab equipment and consumables for demanding geological and petrological research. Our products support the precise sample preparation and analysis needed to identify these key indicators.

Let us equip your lab to uncover the Earth's history. Contact our experts today to discuss your specific laboratory needs.

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What environmental conditions does a vacuum tube furnace provide for copper sintering? Ensure High-Purity Results

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- What are the advantages of using a vacuum tube furnace for SiCw/2024Al composites? Ensure Pure, High-Strength Results.

- Why is a high-precision vacuum tube furnace required for preparing noble metal catalysts? Unlock Sensor Sensitivity