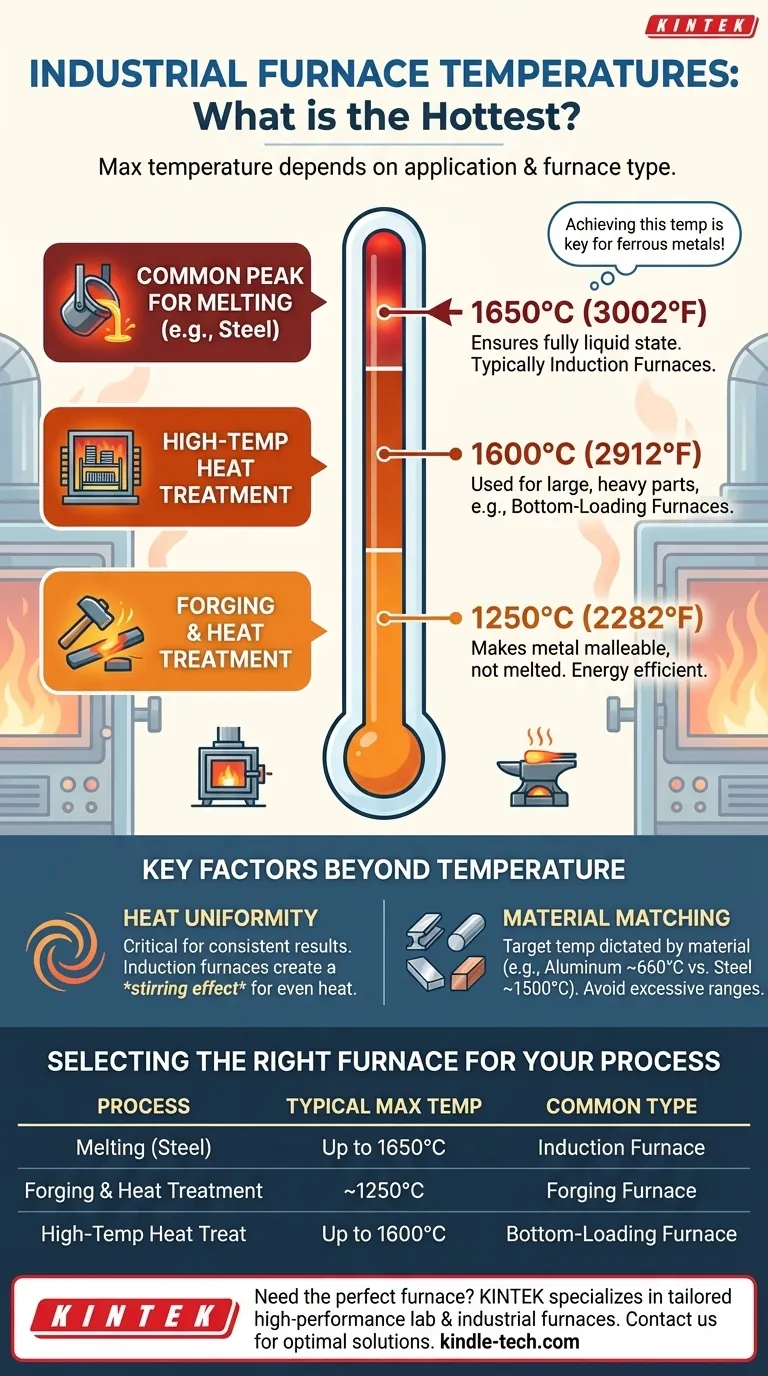

In industrial applications, the maximum achievable temperature in a furnace depends entirely on its specific type and intended purpose. While some specialized laboratory furnaces can reach higher, a common peak temperature for industrial melting is approximately 1650°C (3002°F), typically achieved in an induction furnace.

The maximum temperature of an industrial furnace is not one single number. It is a critical specification directly tied to the furnace's design and the material processing task it was built for, such as melting, forging, or heat treatment.

Why Furnace Temperature Varies by Application

The term "industrial furnace" covers a vast range of equipment. The required temperature for melting steel is fundamentally different from what's needed to simply make it malleable for forging.

Furnaces for Melting

To melt common industrial metals like iron and steel, a furnace must reach extremely high temperatures.

An induction furnace is a prime example, capable of reaching up to 1650°C. This is well above the melting point of steel, ensuring a fully liquid state for casting.

Furnaces for Forging and Heat Treatment

These processes do not require melting the metal. Instead, the goal is to heat it until it becomes soft and workable (malleable) or to alter its crystalline structure.

For forging applications, a temperature of around 1250°C (2282°F) is often sufficient. Operating at this lower temperature is more energy-efficient and prevents accidental melting.

Other High-Temperature Furnace Designs

Different furnace designs can achieve similar, but distinct, peak temperatures based on their construction and heating elements.

For example, a bottom-loading furnace, often used for heat-treating large or heavy parts, might have a maximum operating temperature of 1600°C (2912°F).

Understanding Key Furnace Characteristics

Simply reaching a high temperature is only part of the story. The quality and efficiency of the heating process are equally important.

Maximum Temperature vs. Heat Uniformity

Achieving a peak temperature is one metric, but ensuring the entire workpiece is heated evenly is critical for consistent results.

Induction furnaces excel at this. The alternating magnetic field used for heating also creates a stirring effect within the molten metal, promoting a highly uniform temperature and chemical composition throughout the batch.

Matching Furnace to Material

The target temperature is dictated by the material being processed. A furnace designed for melting aluminum (melting point ~660°C) would be entirely different from one designed for melting steel (melting point ~1500°C).

Choosing a furnace with an excessive temperature range for a low-temperature process leads to wasted energy and potential damage to the material.

Selecting the Right Furnace for Your Process

Your specific industrial goal determines the necessary furnace specifications. A clear understanding of your application is the first step toward choosing the right equipment.

- If your primary focus is melting ferrous metals like steel or iron: You need a high-temperature furnace, like an induction model, capable of consistently operating at or above 1650°C.

- If your primary focus is forging or advanced heat treatment: A furnace with a maximum temperature in the 1250°C to 1600°C range will provide the necessary heat without the energy cost of a dedicated melting furnace.

Ultimately, matching the furnace's capabilities to your specific material and process requirements is the key to achieving an efficient and successful outcome.

Summary Table:

| Process Type | Typical Maximum Temperature | Common Furnace Type |

|---|---|---|

| Melting (e.g., Steel) | Up to 1650°C (3002°F) | Induction Furnace |

| Forging & Heat Treatment | ~1250°C (2282°F) | Forging Furnace |

| High-Temp Heat Treatment | Up to 1600°C (2912°F) | Bottom-Loading Furnace |

Need the perfect furnace for your specific material and process? At KINTEK, we specialize in providing high-performance lab equipment and industrial furnaces tailored to your exact requirements. Whether you're melting metals or performing precise heat treatments, our experts will help you select a furnace that delivers optimal temperature control, uniformity, and energy efficiency. Contact us today to discuss your project and get a personalized solution!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can pyrolysis be done in a furnace? Yes, with the right oxygen-free reactor design.

- What are the safety precautions for heat treatment furnace? Protect Your Lab from Extreme Heat and High Voltage

- What is the difference between annealing and process annealing? A Guide to Choosing the Right Heat Treatment

- Why Use a Vacuum Furnace for Low-Temp Hydrogen Research? Achieve Zero-Hydrogen Baselines for Precise Data

- What is the process of sintering in the iron and steel industry? A Key Step for Efficient Blast Furnace Operation

- What is regeneration gas? A Key to Efficient and Continuous Industrial Purification

- What function does a vacuum environment serve in a high-temperature furnace? Protect Fe-Si Alloy Thermal Cycle Tests

- What role does a high-vacuum heat treatment furnace play in titanium-plated diamond surfaces? Achieve Superior Bonding