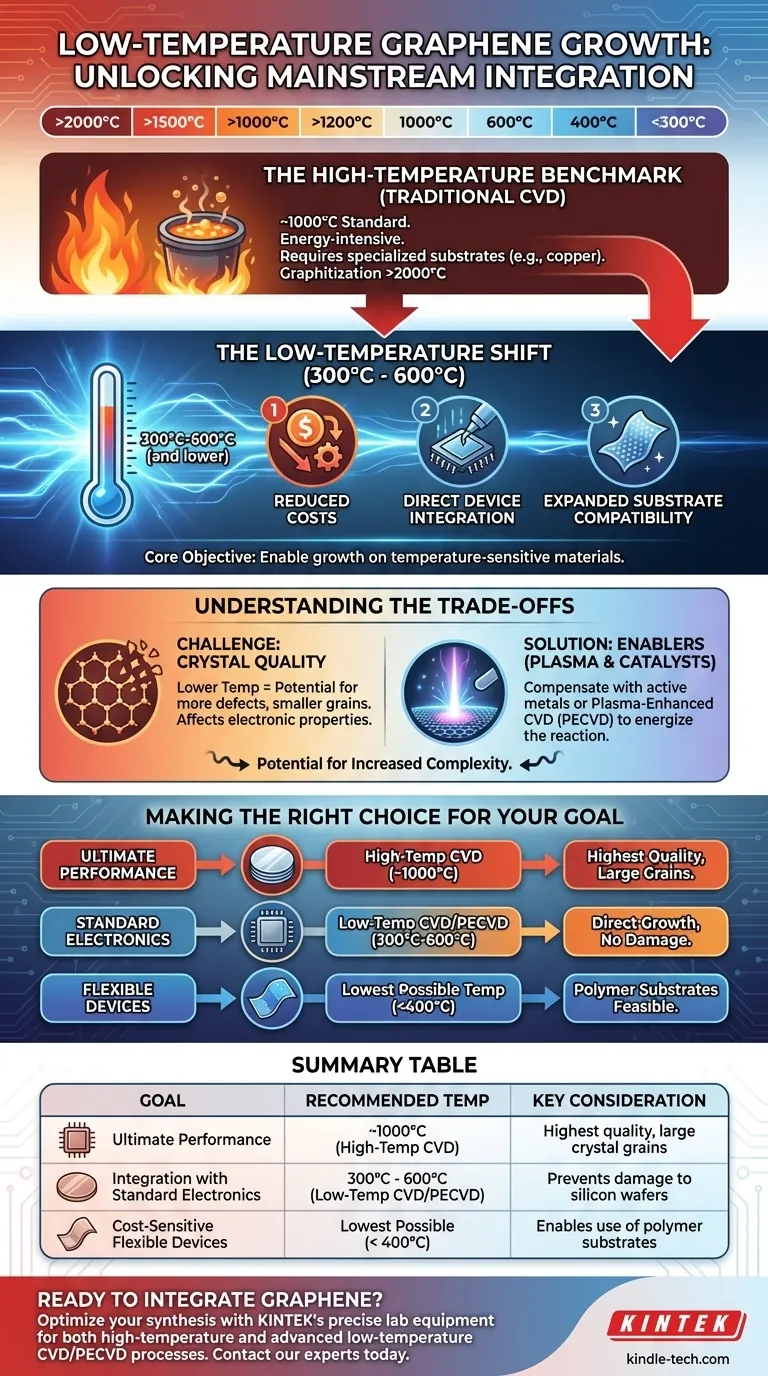

In the context of modern material science, "low-temperature" graphene growth refers to any synthesis process operating significantly below the conventional standard of ~1000°C. Advanced techniques have successfully demonstrated growth at temperatures ranging from 300°C to 600°C, and in some research settings, even lower.

The core objective of lowering graphene's growth temperature is to reduce energy consumption and enable its direct synthesis on temperature-sensitive substrates, like those used in consumer electronics. This strategic shift moves graphene from a specialized material to one that can be integrated into mainstream manufacturing processes.

The High-Temperature Benchmark

To appreciate the significance of low-temperature growth, it is essential to understand the traditional high-temperature landscape of carbon materials. This context frames the entire challenge.

Traditional Graphitization

The conversion of amorphous carbon into crystalline graphite, a process known as graphitization, historically requires extreme temperatures, often exceeding 2000°C. This sets a precedent for the high thermal energy needed to form ordered carbon structures.

Standard Graphene CVD

The gold standard for producing high-quality, large-area graphene is Chemical Vapor Deposition (CVD) on a copper catalyst. This well-established method typically operates at around 1000°C, a temperature that melts many common materials and demands specialized, high-cost equipment.

Why Pursue Lower Temperatures?

The drive to reduce synthesis temperature is not merely an academic exercise. It is a critical step toward unlocking the commercial potential of graphene for a wide range of applications.

Reducing Production Costs

High temperatures equate to high energy consumption. According to the provided references, lowering the thermal budget of the growth process directly reduces operational costs, making graphene production more economically viable at scale.

Enabling Direct Device Integration

Perhaps the most significant advantage is compatibility. Standard electronic components, such as a finished silicon wafer with integrated circuits, cannot withstand 1000°C. Low-temperature growth allows graphene to be synthesized directly onto these functional substrates, eliminating a complex and potentially damaging transfer process.

Expanding Substrate Compatibility

Beyond electronics, many promising applications for graphene involve flexible polymers, plastics, or glass. These materials would be destroyed at conventional CVD temperatures. A lower-temperature process makes these innovative applications feasible.

Understanding the Trade-offs

Reducing the growth temperature introduces a new set of engineering challenges. This is not a simple improvement but a balance of competing factors.

The Challenge of Crystal Quality

Thermal energy is crucial for helping carbon atoms arrange themselves into graphene's perfect hexagonal lattice. Lowering the temperature can result in a higher density of defects, smaller crystal grain sizes, and impurities, which can degrade the material's exceptional electronic and mechanical properties.

The Critical Role of Catalysts and Plasma

To compensate for the lack of thermal energy, low-temperature methods often rely on more advanced techniques. This can involve using highly active metal catalysts or employing Plasma-Enhanced CVD (PECVD), which uses an energized gas to facilitate the reaction without extreme heat.

Potential for Increased Complexity

While the temperature is lower, the overall process can become more complex. Controlling a stable plasma or developing novel catalysts can require more sophisticated equipment and tighter process controls, potentially offsetting some of the initial energy cost savings.

Making the Right Choice for Your Goal

The ideal growth temperature is not a single number; it is defined by the requirements of the final application.

- If your primary focus is ultimate electronic performance for research: High-temperature CVD (~1000°C) remains the benchmark for producing the most pristine, defect-free graphene.

- If your primary focus is integration with standard electronics: Low-temperature processes (300°C - 600°C) are essential for direct growth on silicon wafers without damaging existing components.

- If your primary focus is cost-sensitive flexible devices: The lowest possible process temperatures are necessary to use polymer substrates, even if it requires accepting a modest compromise in material quality.

Ultimately, selecting the right growth temperature is a strategic decision that aligns the physical limits of your materials with your final application's performance and cost requirements.

Summary Table:

| Goal | Recommended Growth Temperature | Key Consideration |

|---|---|---|

| Ultimate Electronic Performance | ~1000°C (High-Temp CVD) | Highest quality, large crystal grains |

| Integration with Standard Electronics | 300°C - 600°C (Low-Temp CVD/PECVD) | Prevents damage to silicon wafers |

| Cost-Sensitive Flexible Devices | Lowest Possible (< 400°C) | Enables use of polymer substrates |

Ready to integrate graphene into your manufacturing process? The choice of growth temperature is critical to balancing material quality, cost, and substrate compatibility. At KINTEK, we specialize in providing the precise lab equipment and consumables needed for both high-temperature and advanced low-temperature CVD/PECVD processes. Whether you are developing next-generation electronics or flexible devices, our expertise can help you optimize your graphene synthesis. Contact our experts today to discuss how we can support your laboratory's specific research and production goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond for Thermal Management Applications

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating