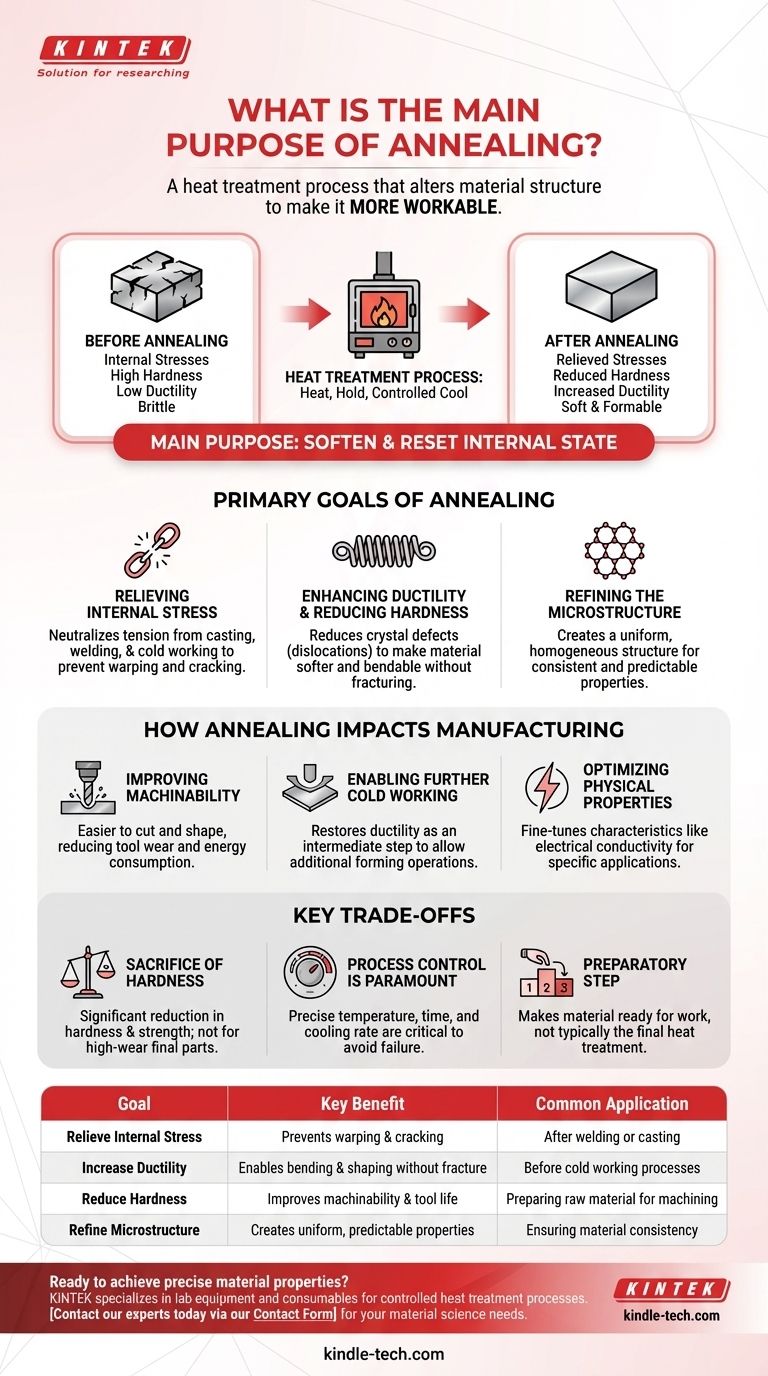

At its core, annealing is a heat treatment process that fundamentally alters a material's internal structure to make it more workable. The main purpose is to relieve internal stresses, reduce hardness, and increase ductility. This is achieved by heating a material to a specific temperature, holding it there for a period, and then cooling it at a controlled rate, effectively making it softer and less brittle.

The central purpose of annealing is to soften a material and reset its internal state. By sacrificing hardness, you gain the ductility and stress relief necessary to machine, form, or further process the material without causing it to fail or crack.

The Primary Goals of Annealing

Annealing is not a single process but a strategy used to achieve several interconnected goals. These goals all revolve around making a material more predictable and easier to work with.

Relieving Internal Stress

Manufacturing processes like casting, welding, and cold working create significant internal stresses within a material.

These hidden stresses can cause warping during subsequent machining or even spontaneous cracking later in the product's life. Annealing allows the material's crystal structure to relax, neutralizing this internal tension.

Enhancing Ductility and Reducing Hardness

Ductility is a material's ability to bend or stretch without fracturing. Annealing increases ductility by reducing the density of crystal structure defects called dislocations.

This reduction in dislocations is also what makes the material softer and less brittle, making it far more suitable for forming operations.

Refining the Microstructure

The process helps produce a more uniform and homogeneous internal structure.

This refinement leads to more consistent and predictable mechanical and physical properties across the entire workpiece, eliminating weak points and ensuring reliability.

How Annealing Impacts Manufacturing

In a practical sense, annealing is a tool used to solve common manufacturing challenges, making processes more efficient and reliable.

Improving Machinability

A softer, less-stressed material is significantly easier to cut, drill, and shape. This improved machinability reduces wear and tear on cutting tools, lowers energy consumption, and often results in a better final surface finish.

Enabling Further Cold Working

Processes like stamping, drawing, or bending harden a material through a phenomenon known as work hardening. As the material gets harder, it also becomes more brittle.

Annealing is often used as an intermediate step to "reset" this effect. It restores ductility, allowing for additional forming operations that would otherwise cause the material to crack.

Optimizing Physical Properties

Beyond purely mechanical traits, annealing can be fine-tuned to improve other characteristics. For some materials, it is used to enhance electrical conductivity or other specific physical properties required for the final application.

Understanding the Key Trade-offs

While incredibly useful, annealing is a process of strategic compromise. Understanding its limitations is critical for proper application.

The Necessary Sacrifice of Hardness

The primary trade-off of annealing is a significant reduction in hardness and strength. An annealed component is soft and is generally not suitable for high-wear or high-stress applications without subsequent hardening treatments like quenching and tempering.

Process Control is Paramount

The effectiveness of annealing depends entirely on precise control of the heating temperature, holding time, and cooling rate. Incorrect parameters can fail to relieve stress, cause undesirable grain growth, or otherwise degrade the material's properties.

It Is a Preparatory, Not a Finishing, Step

It is crucial to view annealing as a preparatory or intermediate process. It makes the material ready for subsequent work but is not typically the final heat treatment for parts that require high final strength.

Making the Right Choice for Your Goal

Specifying an annealing step depends entirely on the material's starting state and your desired manufacturing outcome.

- If your primary focus is preparing a material for extensive machining: Anneal the raw stock to reduce tool wear and prevent stress-induced warping during the process.

- If your primary focus is forming a complex shape via cold working: Use annealing between forming stages to restore ductility and prevent material failure.

- If your primary focus is ensuring the long-term stability of a precision part: Anneal the component after fabrication steps like welding to relieve stresses that could cause future distortion.

By strategically applying annealing, you gain precise control over a material's internal state, ensuring its reliability through every stage of manufacturing and into its final service.

Summary Table:

| Primary Goal | Key Benefit | Common Application |

|---|---|---|

| Relieve Internal Stress | Prevents warping and cracking | After welding or casting |

| Increase Ductility | Enables bending and shaping without fracture | Before cold working processes |

| Reduce Hardness | Improves machinability and tool life | Preparing raw material for machining |

| Refine Microstructure | Creates uniform, predictable properties | Ensuring material consistency and reliability |

Ready to achieve precise material properties for your lab or production line?

KINTEK specializes in the lab equipment and consumables necessary for controlled heat treatment processes like annealing. Whether you are in R&D or manufacturing, our solutions help you relieve internal stresses, improve material workability, and ensure consistent results.

Contact our experts today via our Contact Form to discuss how we can support your specific material science and laboratory needs.

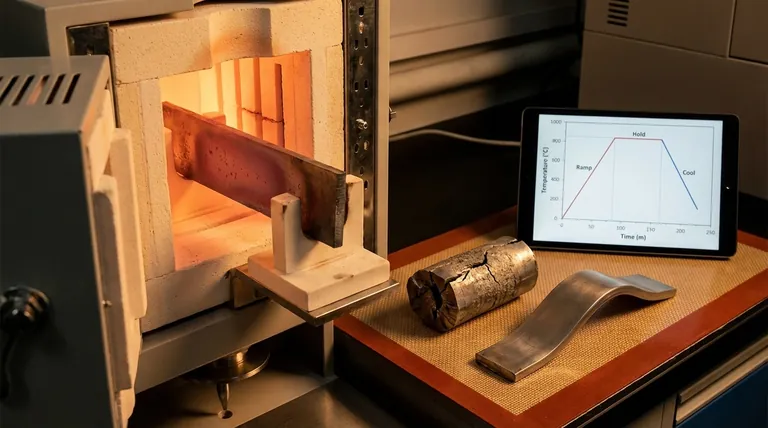

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Is plastic pyrolysis oil better than diesel? A Practical Guide to Waste-to-Energy Fuel

- What are the advantages of machine molding? Achieve Mass Production Efficiency and Precision

- Is there a machine to test diamonds? A Guide to Modern Diamond Verification Technology

- What is regeneration carbon? A Sustainable Way to Reuse Activated Carbon

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat

- How long does the sintering process take? From Rapid Forming to Hours of Thermal Precision

- What is sintering of clay materials? The Science of Turning Clay into Durable Ceramics

- Can biomass be used for transportation? A Guide to Biofuels, Processes, and Trade-offs