In short, Hot Isostatic Pressing (HIP) typically operates at pressures between 100 and 200 megapascals (MPa), which is approximately 15,000 to 30,000 pounds per square inch (psi). While some specialized systems can achieve higher pressures, this range covers the vast majority of industrial applications for densifying materials, eliminating porosity in castings, and consolidating metal powders.

The maximum pressure is only one part of the equation. The true power of Hot Isostatic Pressing lies in the precise, simultaneous application of high pressure, elevated temperature, and time to fundamentally change a material's internal structure.

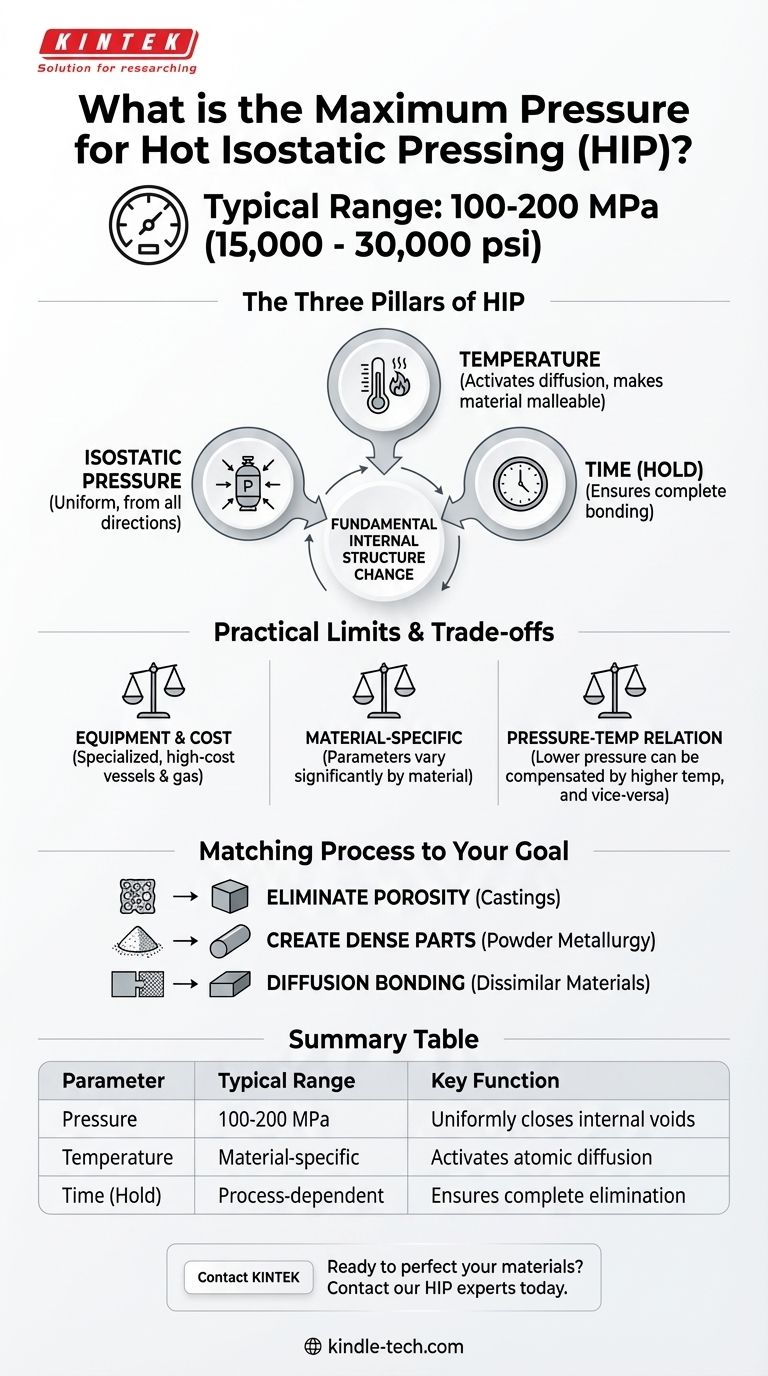

The Three Pillars of Hot Isostatic Pressing

Thinking about HIP in terms of pressure alone is like trying to bake a cake by only focusing on the oven temperature. The final result depends on a careful balance of key ingredients. In this case, the "ingredients" are pressure, temperature, and time.

The Role of Isostatic Pressure

The term "isostatic" means the pressure is uniform and applied equally from all directions. This is the defining characteristic of the process.

This pressure, transmitted by an inert gas like argon, acts as the primary force to physically close internal voids, pores, or defects within a component.

The Critical Function of Temperature

High temperature is what makes the material malleable on a microscopic level. It lowers the material's yield strength, allowing it to deform and flow under pressure.

More importantly, heat activates diffusion, the process where atoms migrate across the surfaces of internal voids, creating a true metallurgical bond and permanently healing the defect.

The Importance of Time (Hold Time)

The final variable is the duration for which the component is held at the target pressure and temperature.

This "hold time" must be long enough for the diffusion process to complete, ensuring that the internal voids are not just closed but are fully bonded and eliminated.

Understanding the Practical Limits and Trade-offs

The capabilities of HIP are not infinite. The interplay between pressure, temperature, and equipment design creates a series of practical trade-offs that influence the cost and application of the process.

Equipment Design and Cost

Achieving and containing extreme pressures and temperatures requires highly specialized and robust equipment. The cylindrical pressure vessels must withstand immense forces.

As target pressures and temperatures increase, the complexity and cost of building and operating the HIP unit rise significantly. The use of expensive inert gases like argon also adds to the operational cost.

Material-Specific Requirements

There is no single "recipe" for HIP. Different materials require vastly different combinations of pressure, temperature, and time.

For example, densifying a titanium casting requires a different set of parameters than consolidating a nickel-based superalloy powder. The optimal settings are always specific to the material and the desired outcome.

The Pressure-Temperature Relationship

In some applications, a lower pressure can be compensated for by a higher temperature, or vice versa.

This trade-off is often determined by the material's sensitivity. Some materials cannot withstand higher temperatures without undergoing undesirable changes in their microstructure, forcing the use of higher pressure instead.

Matching the Process to Your Goal

To apply this knowledge, consider what you are trying to achieve with the material.

- If your primary focus is eliminating porosity in castings: The key is applying sufficient pressure and temperature to close internal voids and enable diffusion bonding across the flaw.

- If your primary focus is creating fully dense powder metallurgy parts: The goal is to use pressure and temperature to consolidate loose powder into a solid billet with properties matching or exceeding those of wrought material.

- If your primary focus is diffusion bonding dissimilar materials: The process uses pressure and heat to force two different materials into intimate contact, allowing atoms to diffuse across the interface and form a strong, solid-state weld.

Ultimately, mastering Hot Isostatic Pressing is about understanding how these three fundamental forces work together to perfect a material from the inside out.

Summary Table:

| Parameter | Typical Range | Key Function |

|---|---|---|

| Pressure | 100 - 200 MPa (15,000 - 30,000 psi) | Uniformly closes internal voids and defects |

| Temperature | Material-specific (e.g., 0.6 - 0.8 Tm) | Activates atomic diffusion for permanent bonding |

| Time (Hold) | Process-dependent | Ensures complete diffusion and defect elimination |

Ready to perfect your materials from the inside out?

Whether your goal is to eliminate porosity in castings, consolidate metal powders, or diffusion bond dissimilar materials, KINTEK's expertise in Hot Isostatic Pressing (HIP) can help you achieve superior material density and performance. Our specialized lab equipment and consumables are designed to meet the precise demands of your laboratory's advanced material processing needs.

Contact our HIP experts today to discuss how we can support your specific application and enhance your material properties.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance