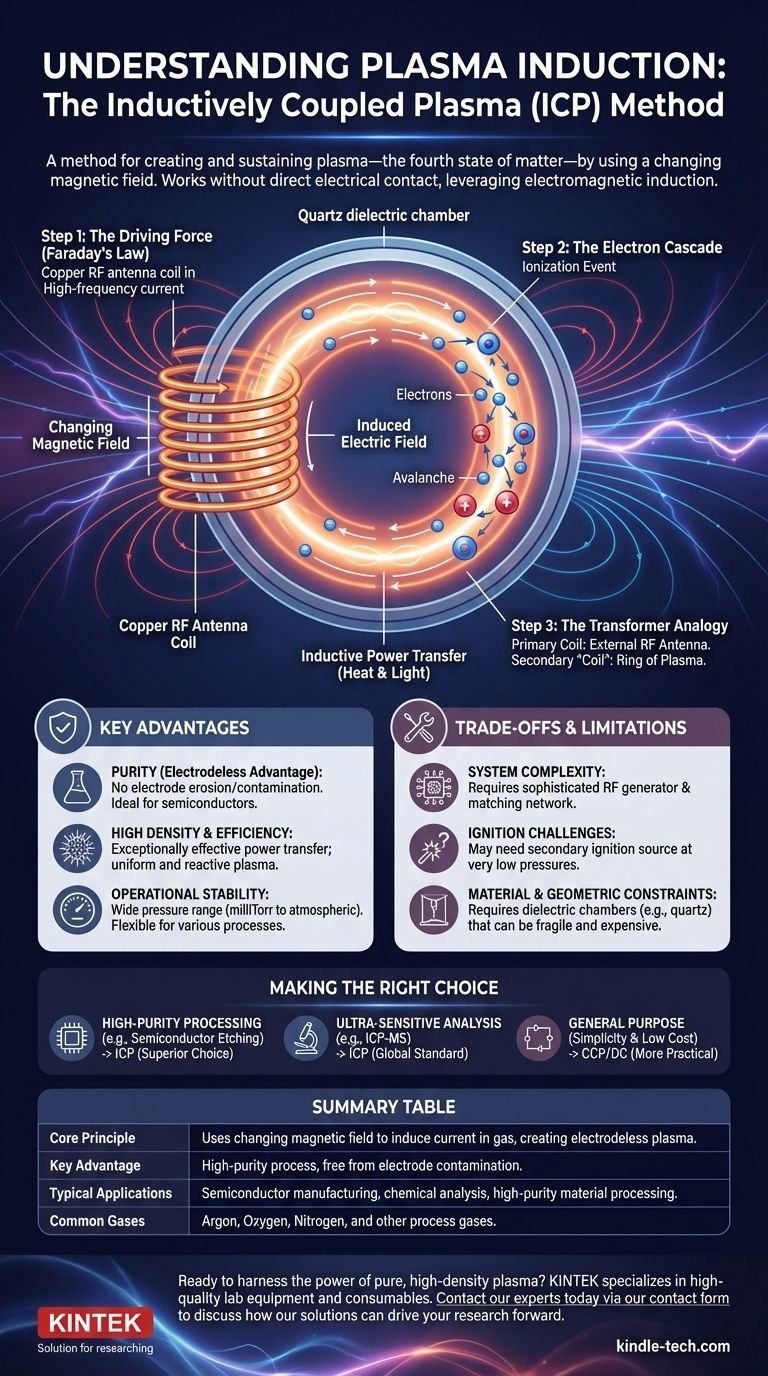

In essence, plasma induction is a method for creating and sustaining plasma—the fourth state of matter—by using a changing magnetic field. This technique, formally known as Inductively Coupled Plasma (ICP), works without direct electrical contact, leveraging the same principle of electromagnetic induction that powers a common transformer.

The central concept to grasp is that plasma induction treats the gas itself as the secondary coil of a transformer. By applying a high-frequency current to an external primary coil, a powerful electric field is induced within the gas, stripping electrons from atoms and igniting the plasma without any electrodes to contaminate the process.

The Core Mechanism: How Induction Creates Plasma

To understand plasma induction, it's best to break it down into a sequence of events governed by fundamental laws of physics. The entire process occurs within a dielectric chamber, typically made of quartz, filled with a low-pressure gas.

Step 1: The Driving Force (Faraday's Law)

A coil, often referred to as the RF (Radio Frequency) antenna, is wrapped around the outside of the chamber. A high-frequency alternating current is passed through this coil.

According to Faraday's Law of Induction, this rapidly changing current generates a changing magnetic field, which in turn induces a circular, oscillating electric field inside the chamber.

Step 2: The Electron Cascade

This induced electric field is the engine of plasma creation. It grabs onto the few free electrons naturally present in the gas and accelerates them in a circular path.

These energized electrons collide with neutral gas atoms. If an electron has enough energy, the collision will knock another electron free from the atom, creating a positive ion and a new free electron. This is called an ionization event.

This process repeats in a chain reaction, or avalanche, rapidly increasing the population of ions and electrons until the gas breaks down into a self-sustaining plasma.

Step 3: The Transformer Analogy

The most intuitive way to visualize this is as an air-core transformer.

- Primary Coil: The external RF antenna carrying the high-frequency current.

- Secondary "Coil": The ring of plasma formed inside the chamber. It acts as a single-turn conductor that is short-circuited on itself.

The power from the external circuit is "inductively" transferred into the plasma, where it is dissipated as heat and light while continuously driving ionization.

Key Advantages of Plasma Induction

The electrodeless nature of ICP gives it distinct advantages that make it indispensable in several high-tech fields.

Purity: The Electrodeless Advantage

Because there are no metal electrodes immersed in the plasma, there is no erosion or "sputtering" of electrode material. This prevents contamination of the plasma and any materials being processed.

This high purity is the primary reason ICP is a cornerstone of the semiconductor industry.

High Density and Efficiency

Plasma induction is exceptionally effective at transferring power into the gas, allowing it to generate very high-density plasmas. These dense plasmas are more uniform and reactive than those created by many other methods.

Operational Stability

ICP sources can be operated stably over a very wide range of pressures, from milliTorr to atmospheric pressure. This flexibility makes them adaptable to many different scientific and industrial processes.

Understanding the Trade-offs and Limitations

While powerful, plasma induction is not a universal solution. It comes with its own set of engineering challenges.

System Complexity

An ICP system requires a sophisticated RF power generator and an impedance matching network. This network is critical for ensuring maximum power is transferred from the generator to the plasma, and its complexity can exceed that of simpler plasma sources like DC or capacitively coupled discharges.

Ignition Challenges

At very low gas pressures, there may not be enough gas atoms to easily start the ionization cascade. In these cases, a secondary ignition source, such as a brief capacitive discharge, may be needed to "seed" the plasma.

Material and Geometric Constraints

The chamber must be made of a dielectric material (an electrical insulator) like quartz or a ceramic to allow the magnetic field to penetrate. These materials can be more fragile and expensive than the metal chambers used in other systems.

Making the Right Choice for Your Application

Inductively Coupled Plasma is a specialized tool. Its use is dictated by the specific requirements of the task at hand.

- If your primary focus is high-purity material processing: ICP is the superior choice for applications like semiconductor etching, where even parts-per-billion contamination from electrodes is unacceptable.

- If your primary focus is ultra-sensitive chemical analysis: The stable, hot, and dense plasma of an ICP source is the global standard for techniques like ICP-MS, used to detect trace elements in environmental, geological, and biological samples.

- If your primary focus is simplicity and low cost for general-purpose plasma: A simpler method like a Capacitively Coupled Plasma (CCP) or a direct-current (DC) glow discharge may be more practical and cost-effective.

Understanding the principles of plasma induction is the first step toward harnessing one of the most powerful and clean methods for manipulating matter at its most fundamental level.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Uses a changing magnetic field to induce a current in a gas, creating plasma without electrodes. |

| Key Advantage | High-purity process, free from electrode contamination. |

| Typical Applications | Semiconductor manufacturing, chemical analysis (ICP-MS), high-purity material processing. |

| Common Gases Used | Argon, Oxygen, Nitrogen, and other process gases. |

Ready to harness the power of pure, high-density plasma for your laboratory processes?

KINTEK specializes in providing high-quality lab equipment and consumables. Whether you are developing next-generation semiconductors or require ultra-sensitive analytical capabilities, our expertise in plasma technology can help you achieve unparalleled purity and efficiency.

Contact our experts today via our contact form to discuss how our solutions can meet your specific laboratory needs and drive your research forward.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Cold Trap Direct Cold Trap Chiller

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- How does a vim furnace work? Achieve Ultimate Purity in High-Performance Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What are the advantages of vacuum induction melting? Achieve Ultimate Purity & Precision for High-Performance Alloys