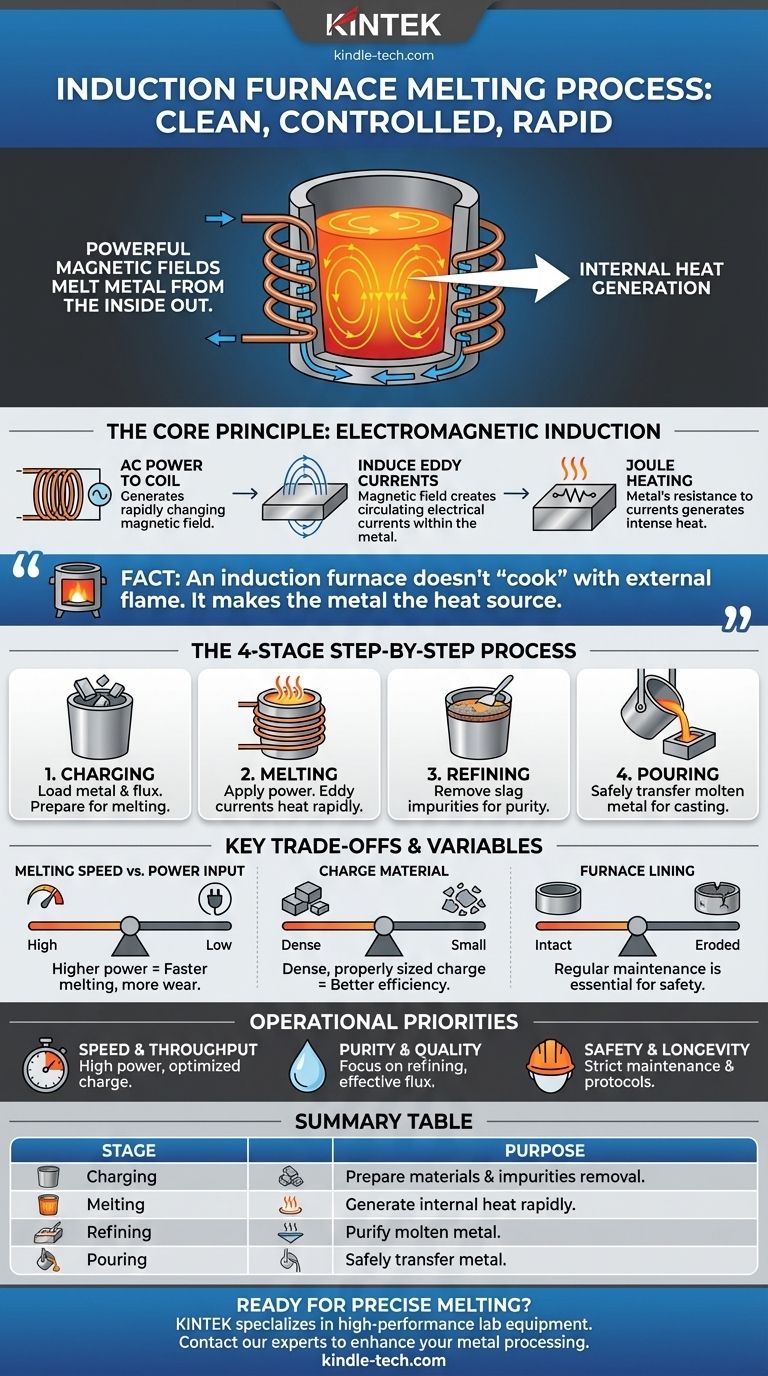

At its core, the melting process in an induction furnace is a clean, controlled method that uses powerful electromagnetic fields to melt metal from the inside out. Unlike a traditional furnace that applies external flame or heat, an induction furnace's copper coil generates a magnetic field. This field induces strong electrical currents within the metal charge itself, and the metal's own resistance to these currents generates intense, rapid heat that leads to melting.

The critical takeaway is that an induction furnace does not "cook" metal with external heat. Instead, it generates a powerful magnetic field that turns the metal itself into the source of heat, leading to a faster, cleaner, and more controllable melt.

The Core Principle: Electromagnetic Induction at Work

To truly understand the melting process, you must first understand the physics that make it possible. The entire operation hinges on a principle discovered by Michael Faraday in the 19th century.

The Alternating Current and the Coil

The process begins with a high-power alternating current (AC) sent through a large, water-cooled copper coil. This coil, which surrounds the crucible holding the metal, is the heart of the furnace. As the current rapidly alternates its direction, it generates a powerful and constantly changing magnetic field in the space within the coil.

Inducing the Eddy Currents

This fluctuating magnetic field penetrates the metallic material (the "charge") placed inside the crucible. According to the laws of electromagnetism, this changing magnetic field induces circulating electrical currents within the metal. These are known as eddy currents.

Joule Heating: Resistance Creates Heat

The final step is simple but powerful. The metal has natural electrical resistance. As the strong eddy currents flow through the metal, they encounter this resistance, which generates immense heat. This phenomenon, known as Joule heating, is what raises the metal's temperature to its melting point and beyond.

The Step-by-Step Melting Process

While the physics are complex, the operational workflow is logical and methodical, generally following four key stages.

Step 1: Charging and Preparation

First, the metal to be melted is placed into the crucible, a refractory container designed to withstand extreme temperatures. The material for the crucible, often graphite or a specific ceramic, is chosen based on the metal being melted. A flux, such as a mix of borax and sodium carbonate, may be added with the charge to help separate impurities during melting.

Step 2: Melting

Power is applied to the coil, initiating the induction heating process. The eddy currents begin heating the metal rapidly. This stage is often accompanied by a distinct humming sound from the furnace. Depending on the furnace's power and the volume of metal, a full melt can be achieved in as little as a few minutes.

Step 3: Refining

Once the metal is fully molten, a refining period begins. During this stage, the flux combines with impurities, forming a lighter layer called slag that floats to the surface. This slag can then be skimmed off, resulting in a cleaner, higher-purity final product.

Step 4: Pouring

After the metal has reached the desired temperature and purity, the furnace is tilted to pour the molten metal into a mold, ladle, or granulation tank. This step must be performed with extreme care to avoid spills and ensure safety.

Understanding the Trade-offs and Key Variables

Achieving an efficient and successful melt requires balancing several competing factors. Understanding these trade-offs is the mark of an experienced operator.

Melting Speed vs. Power Input

The most direct way to increase melting speed is to increase the power supplied to the furnace. However, this also increases energy consumption and can accelerate wear on the furnace lining. The goal is to find the optimal power level for your required throughput without causing excessive stress on the equipment.

The Role of the Charge Material

The size, shape, and density of the metal charge significantly impact efficiency. A densely packed charge allows for better electromagnetic coupling and faster melting. Using charge material that is too small can lead to slower melting, while pieces that are too large may melt unevenly.

Furnace Lining and Maintenance

The intense heat and chemical reactions gradually erode the crucible's refractory lining. This is an unavoidable operational reality. Ignoring regular inspection and repair can lead to a catastrophic failure where molten metal breaks through the lining. Preventative maintenance is not just recommended; it is essential for safety and longevity.

Safety is Non-Negotiable

Working with molten metal is inherently hazardous. Proper personal protective equipment (PPE)—including heat-resistant gloves, an apron, a face shield, and safety goggles—is mandatory. The work area must be clear of any flammable materials, and operators must always be prepared for the possibility of splashes or spills.

Making the Right Choice for Your Goal

Your operational priorities will determine how you approach the melting process.

- If your primary focus is speed and throughput: Prioritize a high-power furnace and optimize your charge with dense, properly sized material to maximize melting efficiency.

- If your primary focus is metal purity and quality: Pay close attention to the refining stage, using the correct flux for your alloy and allowing sufficient time to skim off all slag before pouring.

- If your primary focus is operational safety and furnace longevity: Implement a strict maintenance schedule for the refractory lining and enforce rigorous safety protocols for all personnel.

Ultimately, mastering the induction melting process is a balance of understanding the science, respecting the material, and prioritizing safety.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Charging | Load metal charge & flux into crucible | Prepare materials for melting and impurity removal |

| 2. Melting | Apply power to induce eddy currents | Generate intense internal heat to melt metal rapidly |

| 3. Refining | Skim off slag (impurities) from surface | Purify the molten metal for higher quality |

| 4. Pouring | Tilt furnace to transfer molten metal | Safely transfer metal to mold or ladle for casting |

Ready to achieve precise, efficient metal melting in your lab? KINTEK specializes in high-performance lab equipment, including induction furnaces designed for superior temperature control, rapid melting, and operational safety. Our solutions are tailored to meet the rigorous demands of laboratory environments, ensuring you get the purity and throughput you need.

Contact our experts today to discuss how our induction furnaces can enhance your metal processing capabilities.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting

- What are the limitations of induction brazing? High Costs, Geometric Constraints, and More

- Can an induction heater melt metal? A Guide to Fast, Clean, and Controlled Melting

- How does a melting furnace work? A Deep Dive into Induction and Arc Furnace Technology

- What is the working frequency of an induction furnace? Choosing the Right Frequency for Your Application

- What is the advantage of electric induction furnace compared to direct current EAF during cool start up operation? Faster, More Efficient Melting

- Does induction heating work on gold? The Ultimate Guide to Fast, Efficient Gold Melting

- What is the role of a high-frequency induction melting furnace in ZrCu alloy synthesis? Achieve Maximum Purity