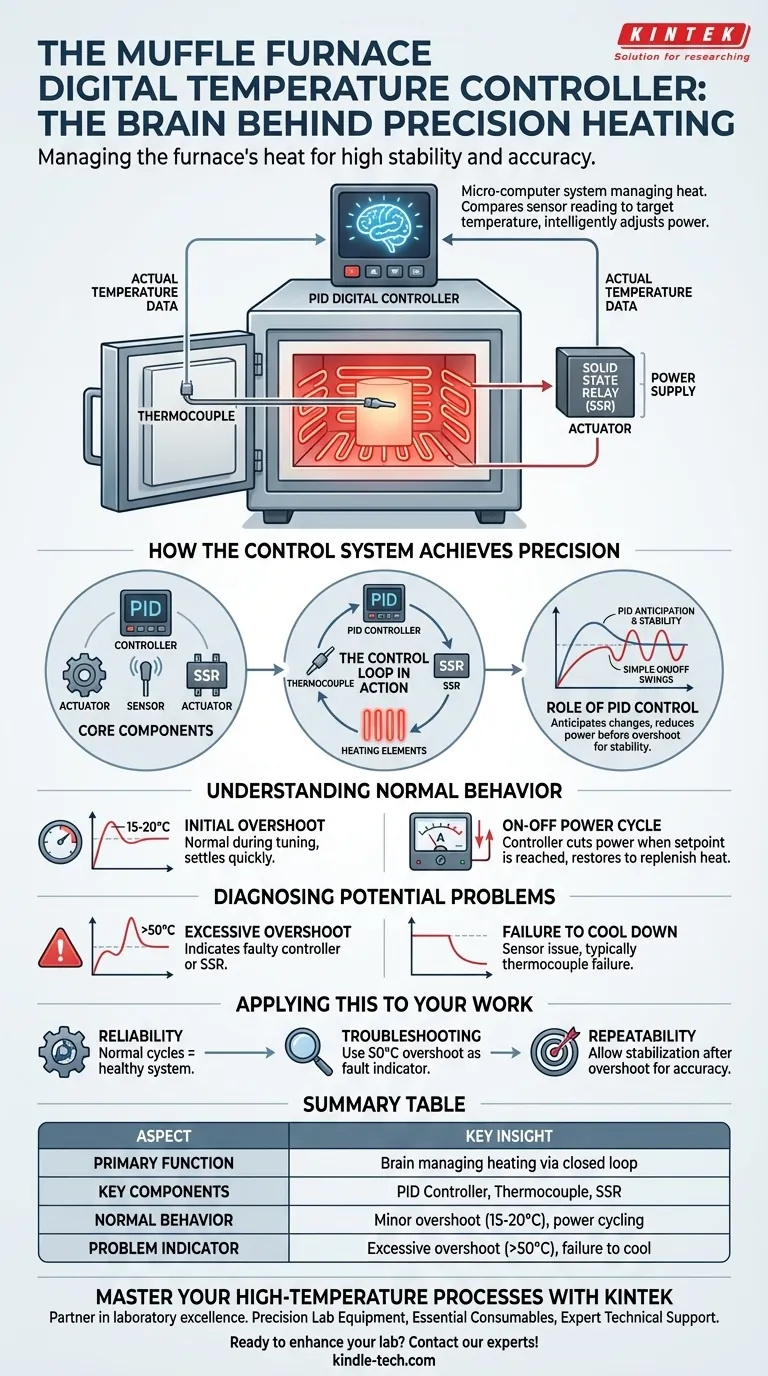

In essence, the digital temperature controller is the brain of a muffle furnace. It is a micro-computer system that precisely manages the furnace's heat. It works by constantly reading the internal temperature from a sensor (a thermocouple) and comparing it to the target temperature you have set. Based on this comparison, it intelligently adjusts the power sent to the internal heating elements, ensuring the furnace reaches and maintains the desired temperature with high stability.

A muffle furnace's value lies in its ability to achieve precise high temperatures. The digital controller is the component that makes this possible, but understanding its normal operating behavior—like minor temperature overshooting—is the key to using the furnace effectively and identifying actual problems.

How the Control System Achieves Precision

A muffle furnace’s heating process is managed by a closed-loop control system. This system consists of three critical parts working in perfect sync.

The Core Components: Controller, Sensor, and Actuator

The controller is the central processing unit, often a sophisticated PID (Proportional-Integral-Derivative) controller.

The sensor is almost always a thermocouple, a robust device that measures the high temperatures inside the chamber and sends that data to the controller.

The actuator is the switch that controls power to the heating elements. This is typically a Solid State Relay (SSR) or a contractor that can turn the high-power elements on and off rapidly.

The Control Loop in Action

The process is a continuous cycle. The thermocouple measures the actual temperature and reports it to the PID controller.

The controller calculates the difference, or "error," between the actual temperature and your setpoint.

Based on this error, the controller signals the SSR to either supply power to the heating elements (if it's too cool) or cut power (if it's too hot).

The Role of PID Control

A simple on/off controller would cause wild temperature swings. A PID controller is far more intelligent.

It doesn't just react to the current temperature; it anticipates future changes. It learns the thermal properties of your specific furnace, allowing it to reduce power before it overshoots the target temperature, resulting in a much more stable and accurate heating process.

Understanding Normal Controller Behavior

The precision of a digital controller can lead to behaviors that may seem alarming but are perfectly normal. Understanding them is crucial for confident operation.

The Initial Temperature Overshoot

It is normal for a muffle furnace to initially exceed the set temperature by 15-20°C.

This is part of the PID controller's tuning process. As it rapidly heats the chamber, it slightly overshoots the target before settling back down to the precise setpoint for stable operation.

The On-Off Power Cycle

During operation, you will notice the ammeter or power indicator fluctuate. The current may drop to zero and then return.

This is the controller actively working. It cuts power when the setpoint is reached and automatically restores power to replenish heat as the furnace naturally cools, keeping the temperature stable.

Diagnosing Potential Problems

While some behaviors are normal, others can indicate a genuine fault in the control system. Knowing the difference prevents unnecessary downtime and ensures safety.

When to Be Concerned: Excessive Overshooting

A normal overshoot is small and temporary. If the furnace temperature exceeds the setpoint by 50°C or more, this indicates a problem.

This could be a faulty controller or a malfunctioning SSR that is "stuck" in the on position, and it requires immediate attention.

Failure to Cool Down

If the controller has cut power but the temperature does not begin to drop after an extended period (e.g., one hour), this often points to a sensor issue.

Most commonly, the thermocouple connection is failing or has burned out. The controller is not receiving an accurate reading, so it cannot manage the system correctly and should be inspected.

Applying This to Your Work

Understanding the temperature controller moves you from a passive user to an informed operator. Use this knowledge to assess performance and diagnose issues.

- If your primary focus is process reliability: Treat the normal on-off cycling and minor overshoots as positive signs of a healthy, active control system.

- If your primary focus is troubleshooting: Use the 50°C overshoot threshold as your key indicator for when a minor fluctuation becomes a potential system fault requiring service.

- If your primary focus is repeatable results: Allow the furnace to reach its setpoint and stabilize after the initial overshoot before placing your sample inside for the most accurate heating.

By understanding the controller's function and feedback, you gain true control over your high-temperature applications.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Primary Function | The "brain" that manages heating via a closed-loop control system. |

| Key Components | PID Controller, Thermocouple (Sensor), Solid State Relay (Actuator). |

| Normal Behavior | Minor initial overshoot (15-20°C) and on-off power cycling are signs of a healthy system. |

| Problem Indicator | Excessive overshoot (>50°C) or failure to cool down signals a potential fault. |

Master Your High-Temperature Processes with KINTEK

Understanding your equipment is the first step to achieving repeatable, reliable results. As your partner in laboratory excellence, KINTEK provides not only top-tier muffle furnaces with advanced digital controllers but also the expert support to ensure you get the most out of your investment.

We specialize in serving your laboratory needs with:

- Precision Lab Equipment: Including muffle furnaces designed for accurate temperature control and long-lasting performance.

- Essential Consumables: Everything you need to keep your lab running smoothly.

- Expert Technical Support: Get answers and solutions from specialists who understand your applications.

Ready to enhance your lab's capabilities? Let's discuss how our solutions can bring precision and reliability to your work.

Contact our experts today for a consultation!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Multi-zone Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the cooling rate of a muffle furnace? Understanding Its Slow, Passive Nature

- What is the importance of a muffle? Achieve Purity and Precision in High-Temperature Processes

- What are the roles of laboratory drying ovens and muffle furnaces in biomass analysis? Precision Thermal Treatment

- What core functions does a high-temperature muffle furnace perform in Fe2O3–CeO2 synthesis? Key Roles in Crystallization

- What is the muffle furnace used for ash content? Achieve Accurate Gravimetric Analysis