In short, the primary objective of an induction furnace is to melt electrically conductive metals, or heat them for processes like forging and heat treatment, using the principle of electromagnetic induction. This method generates heat directly within the material itself, offering a clean, fast, and highly controllable alternative to fuel-fired furnaces or electric arc furnaces.

The fundamental goal is not just to melt metal, but to do so with exceptional precision, purity, and efficiency. By turning the metal itself into the heat source, the induction furnace eliminates external contaminants and provides unparalleled control over the final product's temperature and chemistry.

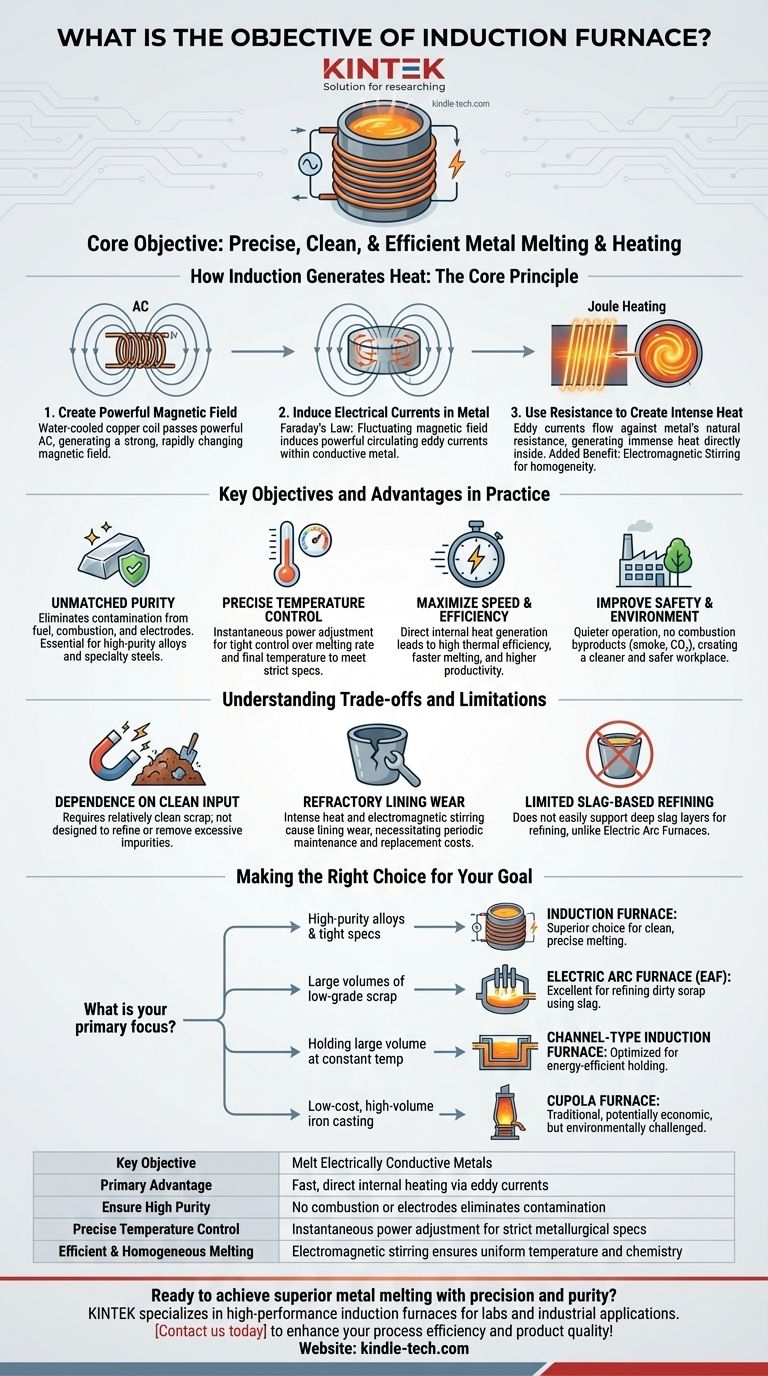

The Core Principle: How Induction Generates Heat

To understand the objective of an induction furnace, you must first grasp its unique working principle. Unlike other furnaces that burn fuel or create an arc to transfer heat to the metal, an induction furnace heats the metal from within.

Step 1: Creating a Powerful Magnetic Field

The furnace is built around a water-cooled coil made of copper. A powerful alternating current (AC) is passed through this coil.

This creates a strong, rapidly changing magnetic field in the space within and around the coil, where the metal to be melted (known as the charge) is placed.

Step 2: Inducing Electrical Currents in the Metal

According to Faraday's law of induction, this fluctuating magnetic field induces powerful electrical currents within the conductive metal charge. These circulating currents are known as eddy currents.

Step 3: Using Resistance to Create Intense Heat

The metal charge has natural electrical resistance. As the strong eddy currents flow against this resistance, they generate immense heat through a process called Joule heating.

Think of it like a wire in an appliance getting warm when electricity flows through it, but magnified to a level capable of melting steel, iron, copper, or aluminum. The heat is generated inside the metal, making the process incredibly fast and efficient.

The Added Benefit: Natural Stirring

A secondary effect of the strong magnetic fields and eddy currents is a powerful stirring action within the molten metal bath. This electromagnetic stirring ensures the melt is homogenous, with a uniform temperature and chemical composition, which is critical for producing high-quality alloys.

Key Objectives and Advantages in Practice

The unique heating method of an induction furnace gives it several key advantages that define its purpose in modern industry.

Achieve Unmatched Purity

Because there is no fuel, no combustion, and no electrodes touching the metal, the risk of contamination from elements like carbon or sulfur is virtually eliminated. This makes induction furnaces essential for producing high-purity alloys, superalloys, and specialty steels.

Exercise Precise Temperature Control

The power supplied to the coil can be adjusted instantaneously and with great precision. This gives operators tight control over the melting rate and the final temperature of the molten bath, allowing them to meet strict metallurgical specifications every time.

Maximize Speed and Efficiency

Since heat is generated directly within the charge, thermal efficiency is very high. Melting starts quickly, reducing the time a batch spends in the furnace. This leads to higher productivity and lower energy loss compared to methods that rely on external heat transfer.

Improve Workplace Safety and Environment

Induction furnaces are significantly quieter and produce no combustion byproducts like smoke, CO₂, or other pollutants at the point of use. This creates a cleaner, safer, and more environmentally friendly working environment in foundries and steel mills.

Understanding the Trade-offs and Limitations

While powerful, induction furnaces are not the universal solution for all melting applications. Understanding their limitations is crucial for proper deployment.

Dependence on Clean Input Material

The induction process is a melting technology, not a refining one. It cannot easily remove impurities like excessive rust (oxides), dirt, or other non-metallics from the charge. Therefore, it requires a supply of relatively clean scrap metal to produce a quality product.

Refractory Lining Wear

The intense, localized heat and the constant electromagnetic stirring place significant stress on the refractory lining (the heat-resistant ceramic crucible holding the metal). This lining wears over time and requires periodic maintenance and replacement, which represents a significant operational cost.

Limited Slag-Based Refining

Unlike an electric arc furnace, an induction furnace does not easily support a deep layer of slag on top of the molten bath. Slag is used in other processes to absorb impurities and refine the metal. The refining capability of an induction furnace is therefore limited.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your specific industrial objective.

- If your primary focus is producing high-purity alloys or specialty metals with tight chemical specifications: The clean melting and precise control of an induction furnace make it the superior choice.

- If your primary focus is melting large volumes of low-grade scrap steel for structural applications: An Electric Arc Furnace (EAF) is more suitable due to its excellent ability to handle and refine dirty scrap using a slag process.

- If your primary focus is holding a large volume of molten metal at a constant temperature with maximum energy efficiency: A channel-type induction furnace is designed specifically for this purpose and outperforms other types.

- If your primary focus is low-cost, high-volume iron casting where chemistry is less critical: A traditional coke-fired cupola furnace may still be a viable economic choice, though it faces increasing environmental pressure.

Ultimately, understanding the objective of an induction furnace is recognizing its role as a tool for precise, clean, and efficient melting.

Summary Table:

| Key Objective | Primary Advantage |

|---|---|

| Melt Electrically Conductive Metals | Fast, direct internal heating via eddy currents |

| Ensure High Purity | No combustion or electrodes eliminates contamination |

| Precise Temperature Control | Instantaneous power adjustment for strict metallurgical specs |

| Efficient & Homogeneous Melting | Electromagnetic stirring ensures uniform temperature and chemistry |

Ready to achieve superior metal melting with precision and purity?

KINTEK specializes in high-performance induction furnaces designed for laboratories and industrial applications requiring clean, efficient, and controlled melting of conductive metals. Whether you're working with high-purity alloys, specialty steels, or need precise heat treatment, our solutions deliver unmatched reliability and results.

Contact us today to discuss how our induction furnaces can enhance your process efficiency and product quality!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys