At its core, Plasma-Assisted Chemical Vapor Deposition (PACVD) is a process for creating high-performance, ultra-thin coatings on a material's surface. Unlike traditional methods that rely purely on high heat, PACVD uses an energized gas, known as plasma, to drive the chemical reactions needed to form the film. This allows the entire process to run at significantly lower temperatures.

The central advantage of PACVD is its ability to deposit durable, high-quality thin films onto temperature-sensitive materials that would be damaged or destroyed by conventional high-heat coating processes.

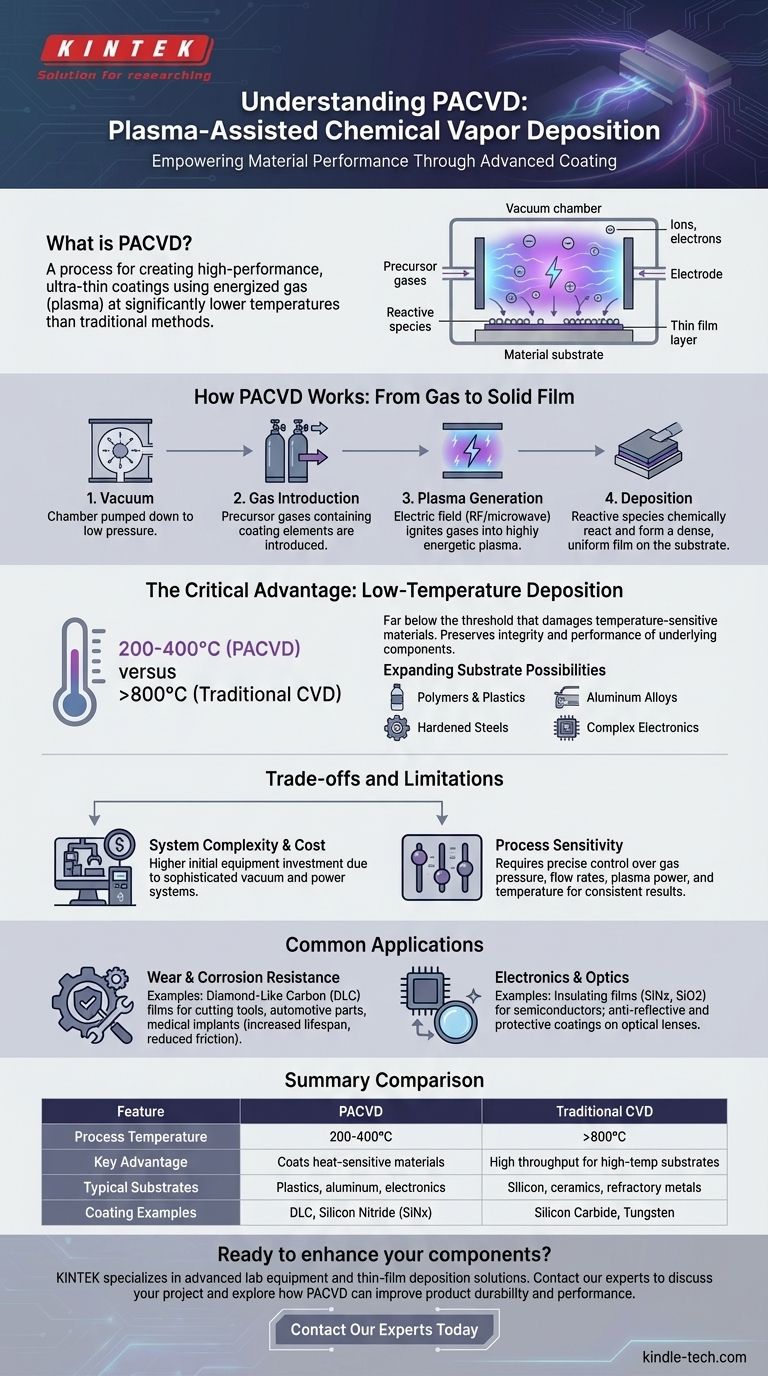

How PACVD Works: From Gas to Solid Film

To understand PACVD, it's helpful to first consider its predecessor, Chemical Vapor Deposition (CVD). Traditional CVD is like baking; it requires a very hot oven (typically >800°C) to provide the energy needed to break down chemical vapors and deposit them as a solid film.

PACVD fundamentally changes the source of that energy.

The Role of Plasma

Instead of relying solely on thermal energy, PACVD introduces energy through plasma—a state of matter where gas is ionized, creating a mix of ions, electrons, and neutral particles.

This plasma, typically generated by applying a radio frequency (RF) or microwave field, is highly energetic. It effectively breaks down the precursor gases into reactive chemical species without needing extreme heat.

Key Process Steps

The process takes place within a vacuum chamber and follows a few key steps:

- Vacuum: The chamber is pumped down to a low pressure.

- Gas Introduction: Specific precursor gases, which contain the elements of the desired coating, are introduced into the chamber.

- Plasma Generation: An electric field is applied, igniting the precursor gases into a glowing plasma.

- Deposition: The highly reactive species from the plasma are drawn to the surface of the component (the substrate), where they chemically react and build up, layer by layer, to form a dense and uniform solid film.

The Critical Advantage: Low-Temperature Deposition

The ability to operate at low temperatures is not just a minor improvement; it is the defining feature of PACVD and the primary reason for its adoption.

Why Lower Temperature Matters

High temperatures can warp, melt, or fundamentally alter the properties of many materials. This makes them incompatible with traditional CVD.

PACVD processes often operate in the 200-400°C range, far below the threshold that would damage many substrates. This preserves the integrity and performance of the underlying component.

Expanding Substrate Possibilities

This low-temperature advantage unlocks the ability to coat a vast range of materials that were previously off-limits, including:

- Polymers and plastics

- Aluminum alloys

- Hardened steels (without affecting their heat treatment)

- Complex electronics

Understanding the Trade-offs and Limitations

While powerful, PACVD is not a universal solution. An objective assessment requires understanding its potential downsides.

System Complexity and Cost

PACVD systems require sophisticated vacuum chambers, gas handling systems, and RF or microwave power generators. This makes the initial equipment investment higher and more complex than some simpler coating methods.

Process Sensitivity

The quality of the final coating is highly dependent on precise control over multiple variables, including gas pressure, flow rates, plasma power, and temperature. Achieving consistent, repeatable results requires significant process expertise.

Common Applications of PACVD Coatings

The unique capabilities of PACVD make it essential in industries where performance and material integrity are paramount.

Wear and Corrosion Resistance

The most common application is creating hard, low-friction coatings. Diamond-Like Carbon (DLC) films, for example, are applied to cutting tools, automotive engine parts, and medical implants to drastically increase their lifespan and reduce friction.

Electronics and Optics

In semiconductor manufacturing, PACVD is used to deposit insulating films like silicon nitride (SiNx) and silicon dioxide (SiO2). It's also used for anti-reflective and protective coatings on optical lenses.

Making the Right Choice for Your Application

Selecting the right coating technology depends entirely on your material and performance goals.

- If your primary focus is coating a heat-sensitive material like plastic or aluminum: PACVD is one of the most effective and reliable choices available.

- If your component can withstand very high temperatures and you need to coat simple shapes: Traditional thermal CVD might be a simpler, more cost-effective option.

- If your primary focus is the absolute lowest equipment cost for a simple application: You may want to investigate non-vacuum processes, but you will sacrifice the performance and adhesion of a PACVD film.

Ultimately, PACVD empowers engineers to enhance materials in ways that were previously impossible, creating surfaces that are far more durable than the underlying component.

Summary Table:

| Feature | PACVD | Traditional CVD |

|---|---|---|

| Process Temperature | 200-400°C | >800°C |

| Key Advantage | Coats heat-sensitive materials | High throughput for high-temp substrates |

| Typical Substrates | Plastics, aluminum alloys, electronics | Silicon, ceramics, refractory metals |

| Coating Examples | DLC, Silicon Nitride (SiNx) | Silicon Carbide, Tungsten |

Ready to enhance your components with high-performance, low-temperature coatings?

KINTEK specializes in advanced lab equipment, including solutions for thin-film deposition. Our expertise can help you determine if PACVD is the right choice for your application on materials like polymers, aluminum, or medical devices.

Contact our experts today to discuss your project and explore how our solutions can improve your product's durability and performance.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures