For a pellet press, the resulting pressure on the material is typically in the range of several hundred Megapascals (MPa), often around 250 MPa for effective compaction. However, the maximum rated pressure for most dies is under 1000 MPa to prevent equipment damage. The actual pressure achieved is a direct result of the force applied by the press and the diameter of the pellet die.

The most critical concept to understand is the distinction between the force applied by the press, measured in kilonewtons (kN), and the resulting pressure on the material, measured in Megapascals (MPa). The pressure is not fixed; it is determined by how much force you apply to a specific die area.

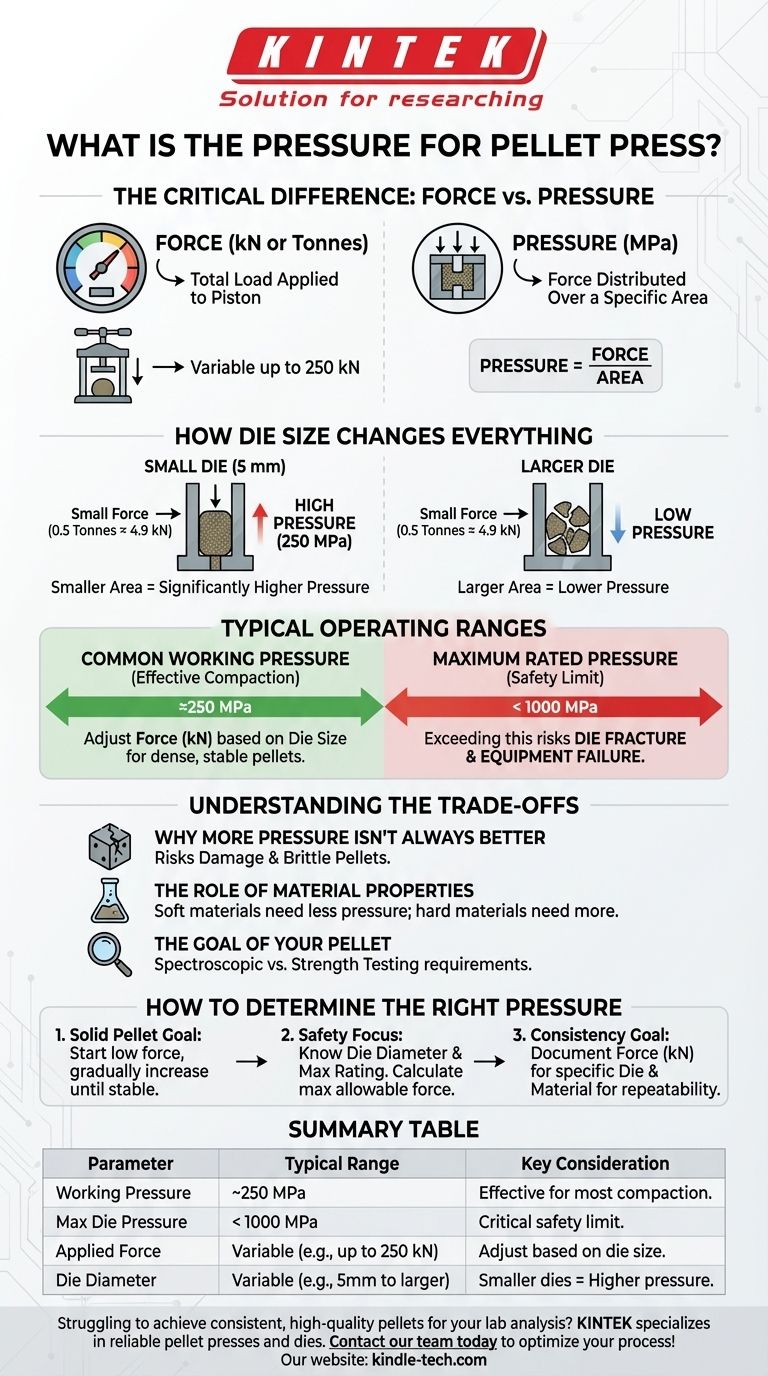

The Critical Difference: Force vs. Pressure

To operate a pellet press effectively and safely, you must understand the relationship between the force your machine generates and the pressure it creates inside the die.

Understanding Force (kN or Tonnes)

The gauge on your hydraulic press measures force, not pressure. This is the total load being applied to the piston.

A manual hydraulic press, for example, might be capable of applying a variable force up to 250 kilonewtons (kN), often displayed in increments of 10 kN.

Understanding Pressure (MPa)

Pressure is the force distributed over a specific area. In this case, it's the force from the press concentrated onto the surface area of the material within the pellet die.

The formula is simple: Pressure = Force / Area. This is the most important factor in creating a quality pellet.

How Die Size Changes Everything

This relationship explains why die size is so critical. A smaller die concentrates the same amount of force into a smaller area, resulting in significantly higher pressure.

For example, a relatively small force of 0.5 tonnes (approximately 4.9 kN) applied to a small 5 mm diameter die can generate a substantial pressure of 250 MPa. Applying that same force to a larger die would result in much lower pressure.

Typical Operating Ranges

While the pressure is variable, there are established working and maximum limits you must respect.

Common Working Pressure

For many applications, a pressure of around 250 MPa is a common and effective target for creating a dense, stable pellet from powdered material.

Achieving this requires adjusting the applied force (kN) on your press according to the specific size of the die you are using.

Maximum Rated Pressure

Pellet dies are not indestructible. They have a maximum rated load to prevent fracture or deformation.

This limit is generally under 1000 MPa. Exceeding this pressure risks catastrophic failure of the die, which is both dangerous and expensive.

Understanding the Trade-offs

Simply applying more force is not always the correct solution. You must balance compaction needs with the physical limits of your equipment.

Why More Pressure Isn't Always Better

Exceeding the required pressure for compaction provides no benefit and introduces significant risk. It can crack the die, damage the press, or even cause the pellet to become brittle and fail. Always operate well below the die's maximum rating.

The Role of Material Properties

Different materials compact differently. Soft, organic powders may require less pressure to form a pellet than hard, crystalline, or metallic materials. The ideal pressure is one that is just sufficient to eliminate voids and form a stable disk.

The Goal of Your Pellet

The required integrity of the pellet also dictates pressure. A pellet for spectroscopic analysis (like a KBr pellet) only needs to be solid and transparent enough for the measurement. A pellet intended for material strength testing may have more demanding compaction requirements.

How to Determine the Right Pressure

Use these principles to find the correct settings for your specific application.

- If your primary focus is creating a solid pellet: Start with a low force and gradually increase it while observing the pellet. The ideal pressure is the point at which a stable, non-crumbling pellet is formed. For many materials, this will be in the range of a few hundred MPa.

- If your primary focus is equipment safety: Always know the diameter of your die and the maximum rated pressure. Calculate the maximum allowable force your press can apply to that die and never exceed it.

- If your primary focus is consistency: Document the force (in kN) that produces a good pellet for a specific die size and material. Using the same force on the same die will produce the same pressure and give you repeatable results.

Mastering the relationship between applied force and die area is the key to producing consistent, high-quality pellets safely.

Summary Table:

| Parameter | Typical Range | Key Consideration |

|---|---|---|

| Working Pressure | ~250 MPa | Effective for most material compaction. |

| Maximum Die Pressure | < 1000 MPa | Critical safety limit to prevent damage. |

| Applied Force | Variable (e.g., up to 250 kN) | Must be adjusted based on die size. |

| Die Diameter | Variable (e.g., 5 mm to larger) | Smaller dies create higher pressure from the same force. |

Struggling to achieve consistent, high-quality pellets for your lab analysis? KINTEK specializes in lab equipment and consumables, providing reliable pellet presses and dies designed for precise pressure control and operator safety. Our experts can help you select the right equipment for your specific materials and application, ensuring perfect compaction results every time. Contact our team today to optimize your pelletizing process and enhance your laboratory's efficiency!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy