The primary advantage of using a tube furnace is its ability to create an exceptionally uniform temperature environment while simultaneously allowing for precise control over the atmosphere surrounding the sample. This combination of thermal consistency and atmospheric isolation makes it an invaluable tool for sensitive material processing, synthesis, and analysis.

A tube furnace is not just a heating device; it is a highly controlled micro-environment. Its core value lies in its power to isolate a sample from the outside world, subjecting it to a precise thermal and atmospheric profile that is difficult to achieve with other furnace types.

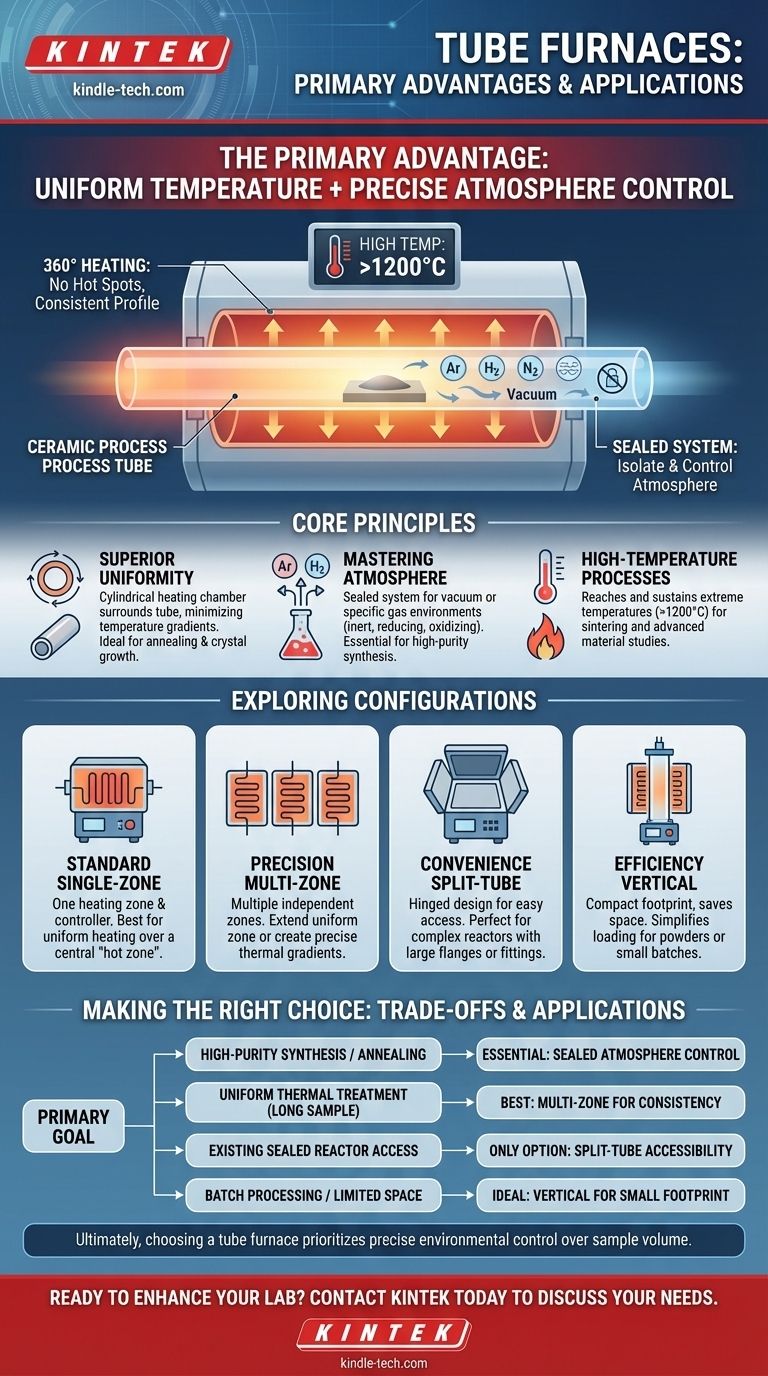

The Core Principles of a Tube Furnace

To understand why a tube furnace is chosen for specific tasks, we must look at its fundamental design principles. These principles are what deliver its signature control and uniformity.

Achieving Superior Temperature Uniformity

The furnace's cylindrical heating chamber, which surrounds a ceramic or quartz tube, is its key design feature. Heating elements are arranged circumferentially around this tube.

This 360-degree heating minimizes hot spots and temperature gradients, ensuring the sample experiences a highly consistent temperature from all sides. This is critical for processes like annealing or crystal growth where uniformity dictates the quality of the final material.

Mastering Atmosphere Control

Unlike a box or muffle furnace that heats in ambient air, a tube furnace is designed as a sealed system.

By fitting flanges onto the ends of the process tube, an operator can create a vacuum to remove contaminants or introduce a specific gas. This enables processes that require inert (e.g., argon), reducing (e.g., hydrogen), or oxidizing atmospheres.

Enabling High-Temperature Processes

Tube furnaces are engineered to safely reach and sustain very high temperatures, often exceeding 1200°C and going much higher with specialized tubes and elements.

This capability makes them essential for sintering advanced ceramics, studying material properties at extreme temperatures, and performing other demanding thermal treatments on small-scale samples.

Exploring Different Tube Furnace Configurations

The basic tube furnace design has been adapted into several specialized configurations, each offering unique advantages for different applications.

The Standard Single-Zone Furnace

This is the most common configuration, featuring a single set of heating elements and one controller. It is ideal for heating a sample to a uniform temperature throughout its central "hot zone."

The Precision of Multi-Zone Furnaces

For longer samples or more complex processes, multi-zone furnaces provide superior control. They feature two, three, or more independent heating zones along the tube's length.

Each zone has its own thermocouple and controller, allowing you to either extend the length of the uniform temperature zone or intentionally create a precise temperature gradient across the sample.

The Convenience of Split-Tube Furnaces

As the name implies, these furnaces are hinged and can be opened into two halves.

This design is exceptionally useful when the process tube has large flanges or fittings that would make it impossible to slide into a solid furnace. It allows for easy placement and removal of complex reactor setups.

The Efficiency of Vertical Furnaces

Orienting the tube furnace vertically offers a compact footprint, saving valuable lab space. This design also simplifies sample loading and unloading, particularly for powders or small batches, and can be advantageous for certain crystal growth or deposition processes.

Understanding the Trade-offs

While powerful, tube furnaces are not a universal solution. Their specialized nature comes with inherent limitations that are critical to understand.

Limited Sample Size and Volume

The most significant limitation is the internal diameter of the process tube. Tube furnaces are fundamentally designed for processing smaller samples, not for bulk heat treatment.

The Cost of Consumables

The process tubes, typically made of quartz, alumina, or mullite, are consumables. They can be fragile, susceptible to thermal shock, and have a finite lifespan, representing an ongoing operational cost.

Complexity in Setup

Achieving precise atmosphere control requires more than just the furnace. It necessitates vacuum pumps, gas lines, flow controllers, and secure flange assemblies, which can add complexity and cost to the initial setup compared to a simple box furnace.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your primary processing goal.

- If your primary focus is high-purity synthesis or annealing: The unparalleled atmosphere control of a sealed tube furnace is essential to prevent oxidation and contamination.

- If your primary focus is uniform thermal treatment: A multi-zone tube furnace offers the highest degree of temperature consistency over the longest possible sample length.

- If your primary focus is working with an existing sealed reactor: The accessibility of a split-tube furnace is the only practical option for inserting and removing your apparatus.

- If your primary focus is batch processing in a space-constrained lab: The small footprint and easy sample loading of a vertical tube furnace make it an ideal choice.

Ultimately, choosing a tube furnace is a decision to prioritize precise environmental control over sample volume.

Summary Table:

| Feature | Benefit |

|---|---|

| 360-Degree Heating | Eliminates hot spots for superior temperature uniformity |

| Sealed Tube Design | Enables vacuum, inert, or reactive gas atmospheres |

| High-Temperature Capability | Safely exceeds 1200°C for demanding thermal processes |

| Configurable Designs | Single-zone, multi-zone, split-tube, and vertical options |

Ready to enhance your lab's material processing capabilities?

A tube furnace from KINTEK provides the precise temperature and atmosphere control your sensitive synthesis and analysis requires. Our expertise in lab equipment ensures you get the right configuration—whether single-zone, multi-zone, split-tube, or vertical—to perfectly match your application.

Contact KINTEK today to discuss your specific needs and discover how our tube furnaces can bring superior control and reliability to your laboratory.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- Is quartz chemically reactive? The Hidden Danger of Freshly Fractured Dust

- What is the primary function of an Alumina (Al2O3) tube in LLZTO sintering? Optimize Your Thermal Processing

- How do high-temperature tube furnaces maintain accuracy in sulfur oxide atmospheres? Ensure Precise Gas Control

- What are the primary functions of a high-temperature tube furnace for iridium-based inverse opals? Expert Annealing Guide

- How does the slow cooling process in a tube furnace affect Li5.7PS4.7Cl1.3 electrolytes? Optimize Dendrite Suppression

- What is the role of secondary calcination in tube or box furnaces? Enhance Sodium-Ion Battery Stability and Performance

- How is a tube furnace utilized in the study of chemical recycling of sulfur-containing polymers? Achieve Closed-Loop Recovery

- What role does a programmable tube furnace play in IrO2/ATO catalyst synthesis? Master Stepped Deposition Today