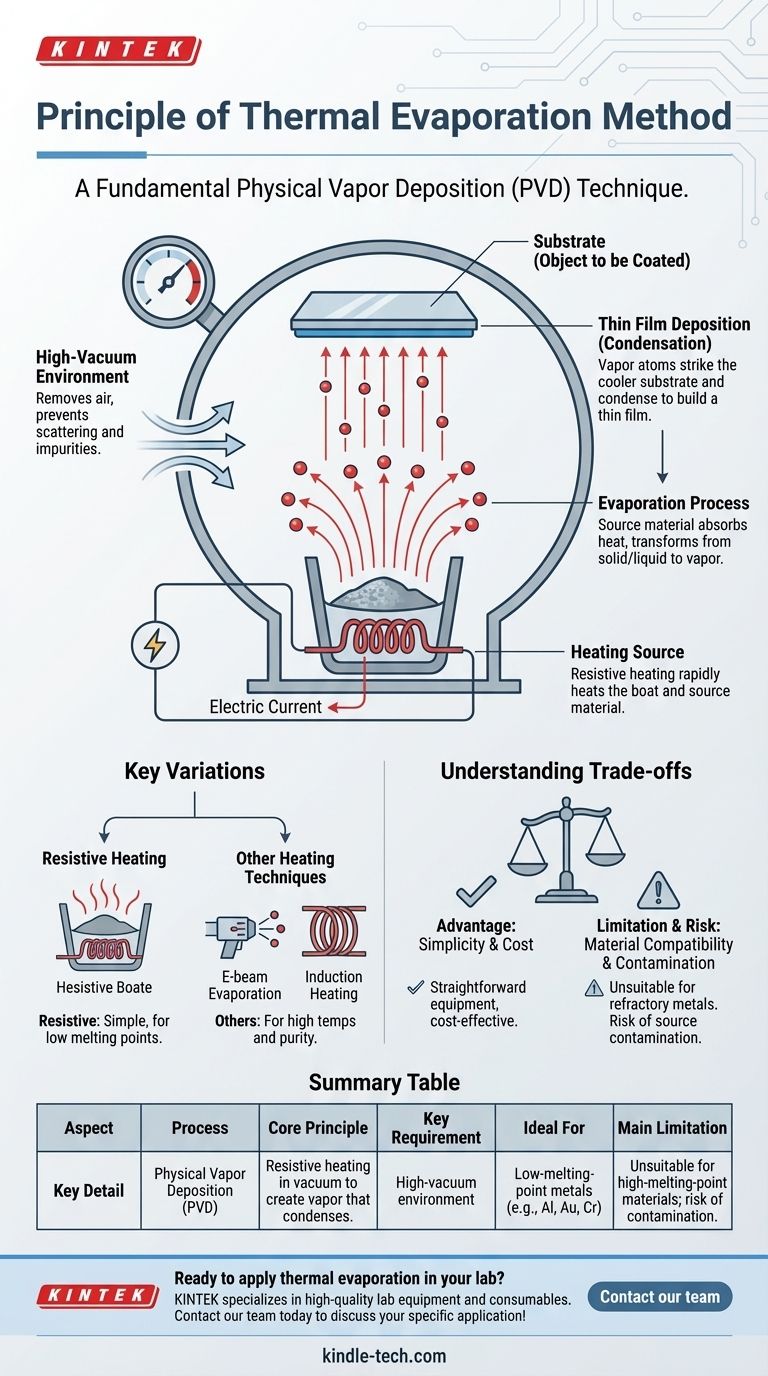

At its core, the principle of thermal evaporation is using heat inside a vacuum to turn a solid material into a vapor, which then travels and condenses onto a cooler surface to create an extremely thin film. This process, often called resistive evaporation, is a fundamental technique in physical vapor deposition (PVD) where electrical resistance is used to generate the necessary heat.

The method is conceptually simple: you "boil" a material in a vacuum chamber so its vapor coats a target. The critical factors, however, lie in managing the vacuum, controlling the heat, and understanding which materials are suitable for this straightforward but limited process.

The Core Mechanism: From Solid to Thin Film

To truly understand the principle, it's best to break the process down into its essential stages. Each step is designed to precisely control the transformation of a bulk material into a uniform, atomic-level coating.

The Vacuum Environment

The entire process must occur in a high-vacuum chamber. This is not an optional detail; it is fundamental to success. The vacuum removes air molecules that would otherwise collide with the vaporized material, scattering them and introducing impurities like oxides into the film.

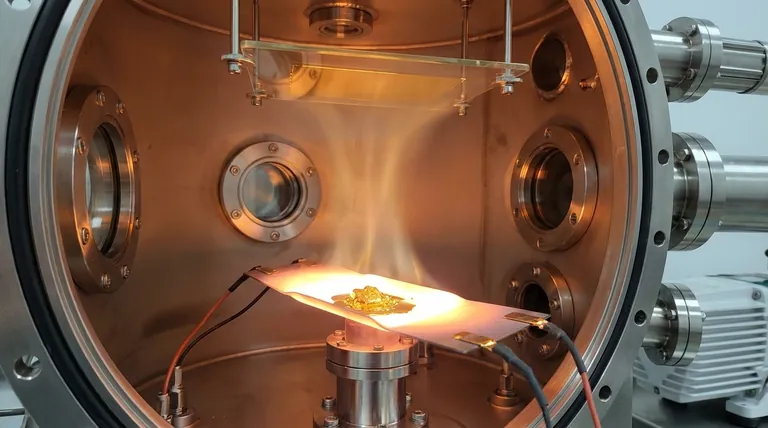

The Heating Source

The material to be deposited, known as the source material or evaporant, is placed in a small container often called a "boat" or "crucible." This boat is typically made from a material with a very high melting point and good electrical conductivity.

An electric current is passed through this boat. Due to its electrical resistance, the boat heats up rapidly, transferring this thermal energy directly to the source material held within it.

The Evaporation Process

As the source material absorbs heat, its atoms gain enough kinetic energy to break their bonds and escape the solid or molten surface. This transition from a solid or liquid state directly into a gaseous state is evaporation. The material has become a vapor.

The Journey and Deposition

Once vaporized, the atoms travel in straight lines through the vacuum chamber. A substrate—the object to be coated—is strategically placed above the source. Because the atoms travel in a direct line-of-sight path, they eventually strike the cooler surface of the substrate.

Upon hitting the substrate, the atoms rapidly lose their energy, condensing back into a solid state. This process occurs atom by atom, gradually building up a thin, uniform film on the substrate's surface.

Key Variations of Thermal Evaporation

While the underlying principle remains the same, the method of heating the source material can vary. This choice is dictated by the material being deposited and the desired quality of the film.

Resistive Heating

This is the classic and most common method described above. It is simple, robust, and effective for materials with relatively low melting points, such as aluminum, gold, and chrome.

Other Heating Techniques

For materials that require extremely high temperatures or higher purity films, more advanced techniques are used. These include Electron Beam (e-beam) Evaporation, where a focused beam of electrons heats the source, and Induction Heating Evaporation, which uses electromagnetic fields.

Understanding the Trade-offs

Like any technical process, thermal evaporation has distinct advantages and disadvantages that make it suitable for some applications but inappropriate for others.

Advantage: Simplicity and Cost

The primary strength of resistive thermal evaporation is its simplicity. The equipment is relatively straightforward and less expensive than more complex deposition systems, making it a common choice in both research labs and industrial settings.

Limitation: Material Compatibility

The method is fundamentally limited by temperature. It is not suitable for refractory metals (like tungsten or molybdenum) or ceramics, which have extremely high melting points that a standard resistive boat cannot reach.

Risk: Source Contamination

A significant drawback is the potential for contamination. The hot crucible or boat can sometimes react with the source material or even evaporate slightly itself, introducing impurities into the final thin film. This limits its use in applications demanding the highest levels of purity.

When to Choose Thermal Evaporation

Your choice of deposition method depends entirely on your material, budget, and quality requirements.

- If your primary focus is cost-effective deposition of simple metals: Thermal evaporation is an excellent and straightforward choice for materials with low melting points like aluminum, copper, or gold.

- If your primary focus is high-purity films or refractory materials: You must consider alternative methods like e-beam evaporation or sputtering to avoid contamination and achieve the necessary temperatures.

Ultimately, understanding these foundational principles allows you to select the right deposition technique to meet your specific material and performance goals.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Physical Vapor Deposition (PVD) |

| Core Principle | Resistive heating of a material in a vacuum to create a vapor that condenses on a substrate. |

| Key Requirement | High-vacuum environment |

| Ideal For | Low-melting-point metals (e.g., Al, Au, Cr) |

| Main Limitation | Unsuitable for high-melting-point (refractory) materials; risk of contamination. |

Ready to apply thermal evaporation in your lab? KINTEK specializes in high-quality lab equipment and consumables for all your deposition needs. Whether you're working with simple metals or require more advanced solutions, our experts can help you select the right tools for precise, cost-effective thin film creation. Contact our team today to discuss your specific application and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What is the deposition rate of e-beam evaporation? Control Thin Film Quality and Speed

- What is the evaporation method of physical vapour deposition? A Guide to High-Purity Thin Film Coating

- What is the electron beam evaporation technique? Achieve High-Purity Thin Film Deposition

- What materials are used in thermal evaporation? From Metals to Dielectrics for Thin-Film Coating

- What materials can evaporate? Master Thin-Film Deposition with the Right Materials

- What properties are involved in evaporation? Master the Key Factors for Efficient Drying

- What is vacuum deposition process? Achieve High-Performance Coatings with Precision

- What are the advantages and disadvantages of evaporative deposition? Achieve High-Purity Thin Films