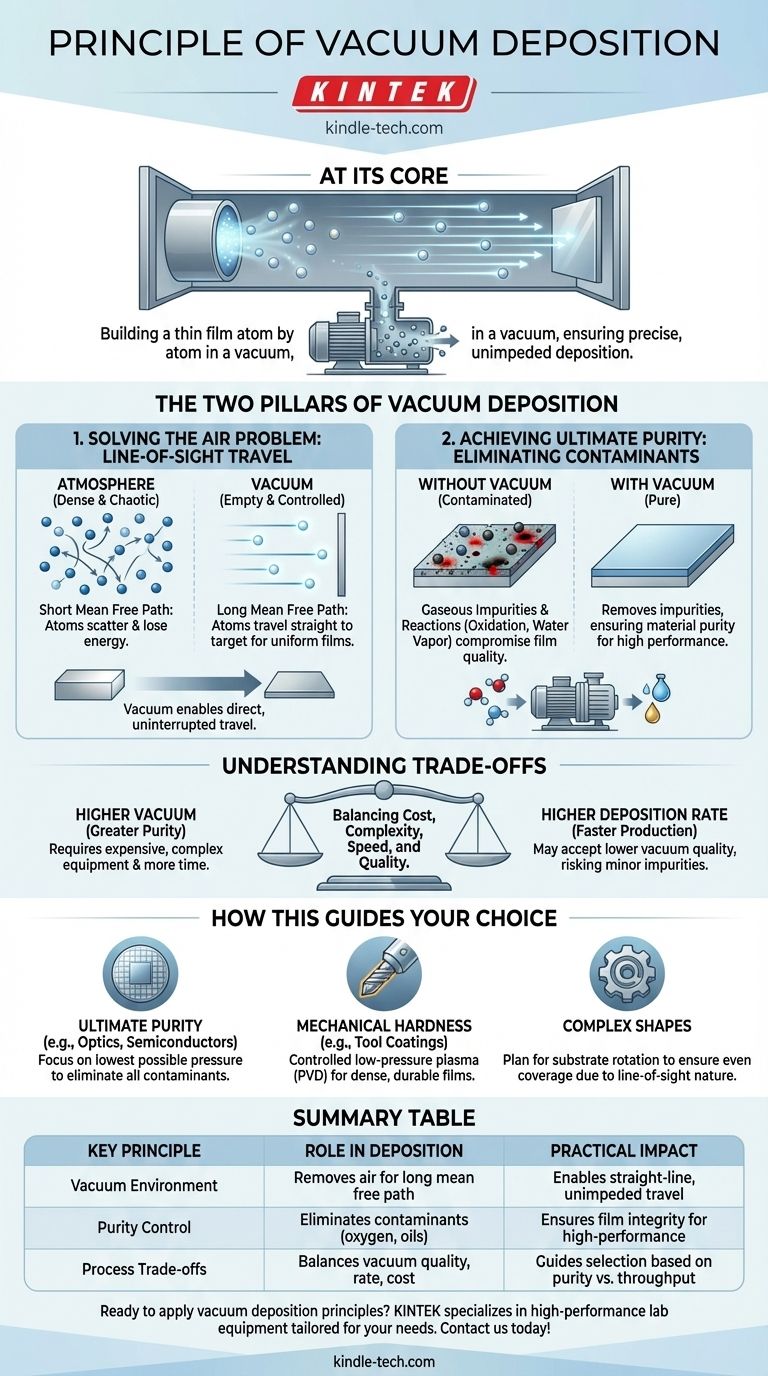

At its core, the principle of vacuum deposition is to build a thin film of material onto a surface, one atom or molecule at a time. This is achieved by creating a vapor of the coating material inside a vacuum chamber, allowing it to travel unimpeded and deposit onto the target surface with extreme precision and purity.

The vacuum is not a passive environment; it is the active solution to two fundamental problems. It ensures material atoms travel in a straight line from their source to the target, and it removes airborne contaminants that would otherwise ruin the quality of the deposited film.

The Fundamental Problem: Air Gets in the Way

To understand vacuum deposition, you must first understand why a normal atmosphere makes this process impossible. The air around us is a dense, chaotic sea of particles.

The Concept of Mean Free Path

Mean free path is the average distance a particle can travel before colliding with another particle. In the atmosphere, this distance is incredibly short—less than a millimeter.

An atom of coating material vaporized at atmospheric pressure would immediately collide with billions of nitrogen and oxygen molecules. It would scatter, lose energy, and never reach its target.

Why a Straight Line is Critical

Vacuum deposition relies on a "line-of-sight" trajectory. By removing virtually all the air molecules from a chamber, the mean free path becomes enormous—longer than the chamber itself.

This allows the vaporized coating atoms to travel in a straight, uninterrupted line from the source directly to the substrate. This control is what enables the creation of uniform, precisely engineered films.

The Risk of Unwanted Reactions

Many materials, when heated to the point of vaporization, are highly reactive. In open air, they would instantly oxidize or react with other gases.

The vacuum eliminates these reactive gases, preventing chemical reactions like oxidation. This ensures the deposited film is composed of the pure, intended material, not an unintended chemical compound.

The Second Pillar: Achieving Ultimate Purity

Beyond enabling particle travel, the vacuum serves as the ultimate cleaning agent, creating an environment free of contaminants that would compromise the film.

Eliminating Gaseous Impurities

A vacuum chamber doesn't just remove air; it also removes water vapor, oils, and other trace gases. These impurities, if present, would be embedded into the growing film.

The Impact on Film Properties

For high-performance applications like semiconductors, optical lenses, or medical implants, even microscopic impurities can be catastrophic.

Contaminants can dramatically alter a film's electrical conductivity, optical transparency, or mechanical strength. A high-quality vacuum is the only way to guarantee the film meets its required performance specifications.

Understanding the Trade-offs

While powerful, vacuum deposition is a process governed by practical limitations and engineering trade-offs.

Cost and Complexity

Creating and maintaining a high-vacuum environment is not trivial. It requires expensive and complex equipment, including robust chambers, multiple types of vacuum pumps, and sensitive pressure gauges. This adds significant cost and operational overhead.

Deposition Rate vs. Film Quality

There is often an inverse relationship between the speed of deposition and the quality of the vacuum. Achieving an ultra-high vacuum (UHV) for maximum purity takes a significant amount of time before the coating process can even begin.

Projects that require high throughput may need to accept a lower-quality vacuum, balancing production speed against the risk of minor impurities.

Not a One-Size-Fits-All Process

"Vacuum deposition" is a broad family of techniques, including Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). The specific method, operating pressure, and source material are all chosen based on the desired film characteristics. There is no single universal process.

How This Principle Guides Your Choice

Understanding the fundamental role of the vacuum allows you to make more informed decisions about your coating requirements.

- If your primary focus is ultimate purity (e.g., semiconductors, sensitive optics): Your most critical parameter is achieving the lowest possible pressure (a high-quality vacuum) to eliminate all contaminants.

- If your primary focus is mechanical hardness (e.g., tool coatings): A controlled, low-pressure plasma environment within the vacuum, often used in PVD, is key to creating a dense and durable film.

- If your primary focus is coating complex 3D shapes: The line-of-sight nature of many vacuum processes means you must plan for substrate rotation and manipulation to ensure even coverage.

By removing the obstacles of atmosphere and contamination, the vacuum transforms the process of coating from an uncontrolled art into a precise science.

Summary Table:

| Key Principle | Role in Vacuum Deposition | Practical Impact |

|---|---|---|

| Vacuum Environment | Removes air molecules to create a long mean free path | Enables straight-line, unimpeded travel of coating atoms |

| Purity Control | Eliminates contaminants like oxygen, water vapor, and oils | Ensures film integrity for high-performance applications |

| Process Trade-offs | Balances vacuum quality, deposition rate, and cost | Guides selection based on purity vs. throughput needs |

Ready to apply vacuum deposition principles to your lab’s projects? KINTEK specializes in high-performance lab equipment and consumables, including vacuum deposition systems tailored for semiconductors, optics, and industrial coatings. Our experts will help you select the right solution for purity, durability, or complex 3D coating needs. Contact us today to discuss how we can enhance your thin-film processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures