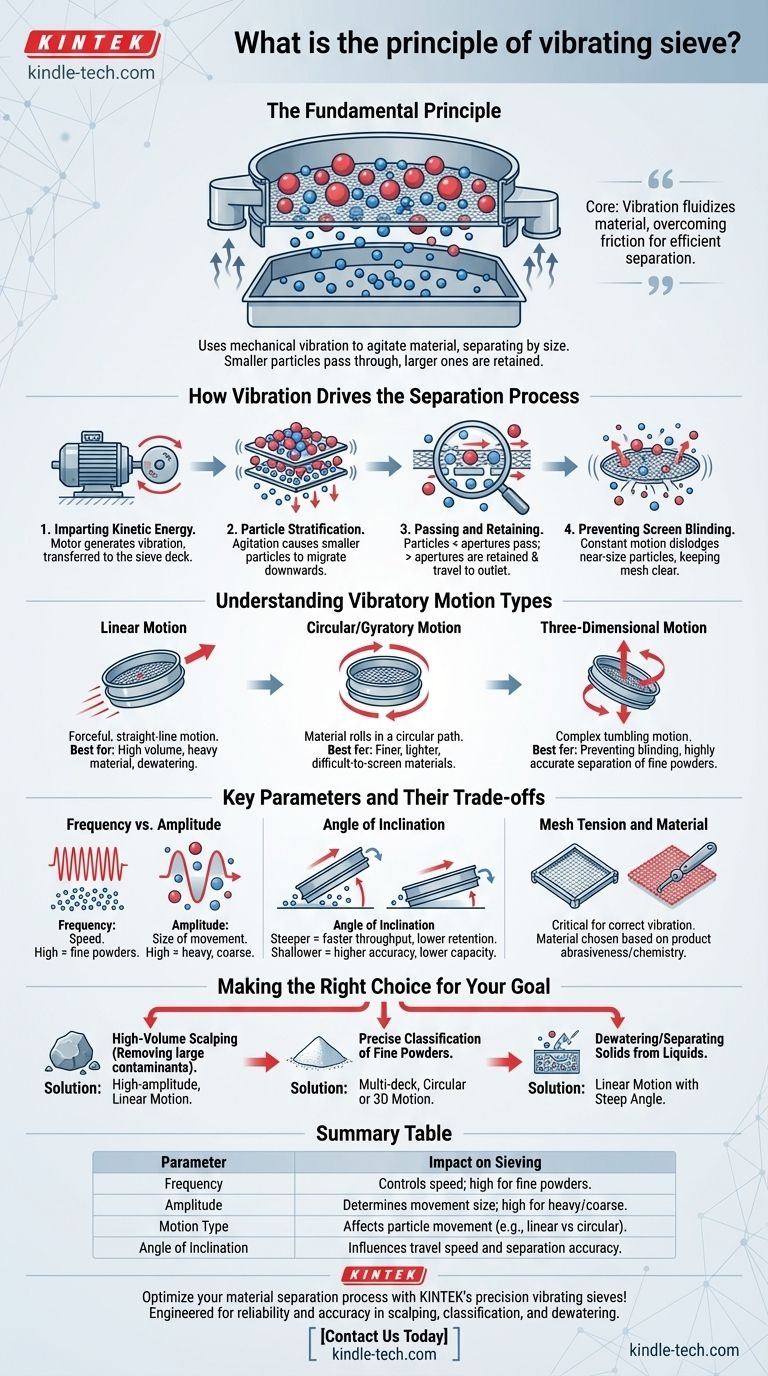

The fundamental principle of a vibrating sieve is to use mechanical vibration to agitate a bed of material on a screen or mesh. This motion causes smaller particles to fall through the screen's openings while retaining the larger particles on top, achieving a physical separation based purely on size.

At its core, a vibrating sieve works by overcoming inter-particle friction and cohesion. The vibration fluidizes the material, giving each particle the opportunity to find an opening in the screen, which dramatically increases the efficiency and accuracy of the separation process.

How Vibration Drives the Separation Process

A vibrating sieve, also known as a vibrating screen, relies on a carefully controlled motion generated by an electric motor. This motion is the engine of the entire separation process.

Imparting Kinetic Energy

An electric motor, typically connected to an eccentric weight or an electromagnetic exciter, generates the vibration. This energy is transferred directly to the sieve deck, which holds the screen mesh.

Particle Stratification

The vibration causes the entire bed of material to move. This agitation makes smaller particles migrate downwards through the larger ones, a process known as stratification. This ensures the finest particles reach the screen surface efficiently.

Passing and Retaining

Once at the screen surface, particles smaller than the mesh openings (apertures) pass through. Particles larger than the openings are retained and travel across the screen surface toward an outlet, effectively separating the material into two or more size fractions.

Preventing Screen Blinding

Without vibration, a screen can quickly clog or "blind," as particles get stuck in the apertures. The constant, vigorous motion of a vibrating sieve dislodges these near-size particles, keeping the mesh clear and ensuring continuous, effective operation.

Understanding Vibratory Motion Types

The specific type of motion has a significant impact on separation efficiency for different materials. The two most common types are linear and circular.

Linear Motion

A linear or straight-line motion forcefully throws the material forward and upward. This is highly effective for moving large volumes of heavy, coarse material and for dewatering applications.

Circular or Gyratory Motion

This motion causes material to roll across the screen surface in a circular path. It keeps particles on the screen for a longer duration, providing more opportunities for them to pass through the mesh. This is ideal for finer, lighter, or difficult-to-screen materials.

Three-Dimensional Motion

Some advanced sieves combine vertical and horizontal movements to create a complex, three-dimensional "tumbling" motion. This is the most effective method for preventing blinding and achieving highly accurate separation of fine, low-density powders.

Key Parameters and Their Trade-offs

Optimizing a vibrating sieve involves balancing several key operational parameters. Adjusting one will invariably affect the others.

Frequency vs. Amplitude

Frequency is the speed of vibration, while amplitude is the size of the movement (stroke). High amplitude is needed to move heavy, coarse materials, while high frequency with low amplitude is better for fluidizing and separating very fine powders.

Angle of Inclination

The angle of the sieve deck controls how quickly material travels across it. A steeper angle increases throughput but reduces retention time, which can lower separation accuracy. A shallower angle increases accuracy but can reduce capacity.

Mesh Tension and Material

The screen mesh itself is critical. It must be properly tensioned to vibrate correctly and prevent premature failure. The material of the mesh (e.g., stainless steel, polyurethane) is chosen based on the abrasiveness and chemical properties of the product being screened.

Making the Right Choice for Your Goal

The ideal setup depends entirely on your material and desired outcome.

- If your primary focus is high-volume scalping (removing large contaminants): A high-amplitude, linear motion sieve is the most efficient choice.

- If your primary focus is precise classification of fine powders: A multi-deck sieve with a circular or three-dimensional motion will provide the necessary accuracy.

- If your primary focus is dewatering or separating solids from liquids: A linear motion screen with a steep angle of inclination will work best.

By controlling the type, frequency, and amplitude of vibration, you can tailor the sieving process to achieve precise and reliable material separation for virtually any application.

Summary Table:

| Parameter | Impact on Sieving |

|---|---|

| Frequency | Controls speed of vibration; high frequency is better for fine powders. |

| Amplitude | Determines size of movement; high amplitude moves heavy, coarse materials. |

| Motion Type | Affects particle movement (e.g., linear for high volume, circular for fine powders). |

| Angle of Inclination | Influences material travel speed and separation accuracy. |

Optimize your material separation process with KINTEK's precision vibrating sieves! Whether you're scalping large contaminants, classifying fine powders, or dewatering solids, our lab equipment is engineered for reliability and accuracy. Contact us today to find the perfect sieve for your laboratory needs and enhance your efficiency with tailored solutions from KINTEK.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- What is the primary purpose of using precision sieving equipment for biomass? Ensure Efficient Hydrothermal Liquefaction

- What is the purpose of using a precision laboratory vibrating sieve? Ensure Flawless Glass-Ceramic Powder Deposition

- What is the role of a precision sieving system in Ag3PO4 preparation? Optimize Phosphate Extraction Efficiency

- How does a standard sieving system contribute to the quality control of recycled concrete aggregates?

- Why is a high-precision sieving system essential for Al2O3/Cu-Cr composites? Achieve Nano-Scale Dispersion & Uniformity

- What is the function of speed control in industrial shakers for gold leaching? Optimize Your E-Waste Recovery

- Is sieve analysis the most commonly used technique for particle size analysis? The Go-To Method for Granular Materials