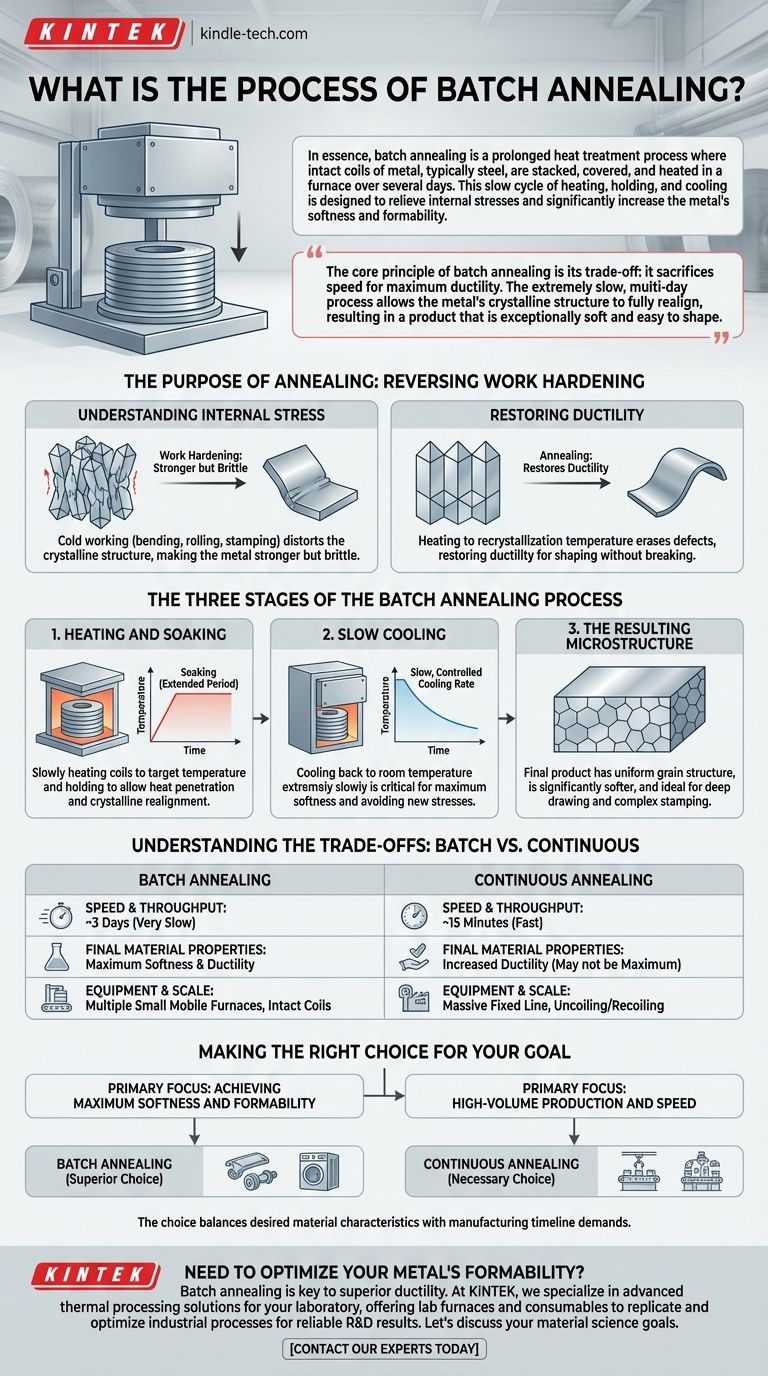

In essence, batch annealing is a prolonged heat treatment process where intact coils of metal, typically steel, are stacked, covered, and heated in a furnace over several days. This slow cycle of heating, holding, and cooling is designed to relieve internal stresses and significantly increase the metal's softness and formability.

The core principle of batch annealing is its trade-off: it sacrifices speed for maximum ductility. The extremely slow, multi-day process allows the metal's crystalline structure to fully realign, resulting in a product that is exceptionally soft and easy to shape.

The Purpose of Annealing: Reversing Work Hardening

Understanding Internal Stress

When metal is bent, rolled, or stamped (a process known as cold working), its internal crystalline structure becomes distorted and stressed. This phenomenon, called work hardening, makes the metal stronger but also more brittle and difficult to form further.

Restoring Ductility

Annealing reverses this effect. By heating the metal to a specific point known as the recrystallization temperature, the process erases the defects caused by cold working. This restores the material's ductility (its ability to be drawn or shaped without breaking).

The Three Stages of the Batch Annealing Process

Stage 1: Heating and Soaking

The process begins by stacking several coils of metal onto a fixed base. A protective cover is placed over the stack, and a large, mobile furnace is lowered on top.

The furnace slowly heats the coils to the target temperature, where the metal's crystal structure becomes malleable but the metal remains solid. The coils are then "soaked"—held at this temperature for an extended period—to ensure the heat penetrates fully and allows the internal structure to repair and realign itself.

Stage 2: Slow Cooling

After soaking, the metal must be cooled back to room temperature at a very slow, controlled rate. This is the most critical phase for achieving maximum softness.

Rapid cooling would lock new stresses into the material, defeating the purpose of the process. Slow cooling allows the new, stress-free crystals to form properly, resulting in a highly ductile final product.

Stage 3: The Resulting Microstructure

The end result of batch annealing is a metal with a uniform, stress-free grain structure. This material is significantly softer and more formable than it was before the process, making it ideal for applications that require deep drawing or complex stamping.

Understanding the Trade-offs: Batch vs. Continuous

Speed and Throughput

This is the most significant difference. Batch annealing is a very slow process, often taking around three days per batch. Continuous annealing, where a single strip of metal is uncoiled and run through a furnace, can take as little as 15 minutes.

Final Material Properties

The extended, slow cycle of batch annealing typically produces the softest, most ductile material possible. While continuous annealing also increases ductility, its rapid nature may not achieve the same absolute level of softness as the batch process.

Equipment and Scale

Batch annealing uses multiple smaller, mobile furnaces to treat large, intact coils. Continuous annealing requires a massive, fixed processing line to handle the uncoiling and recoiling of the metal strip, representing a much larger capital investment.

Making the Right Choice for Your Goal

The decision to use batch annealing is driven entirely by the required properties of the end product and production logistics.

- If your primary focus is achieving maximum softness and formability: Batch annealing is the superior choice for applications like deep-drawn automotive parts or appliance housings.

- If your primary focus is high-volume production and speed: Continuous annealing is the necessary choice for products where extreme ductility is secondary to throughput.

Ultimately, selecting the correct annealing method depends on balancing the desired material characteristics with the demands of the manufacturing timeline.

Summary Table:

| Aspect | Batch Annealing | Continuous Annealing |

|---|---|---|

| Process Time | ~3 Days (Slow) | ~15 Minutes (Fast) |

| Key Benefit | Maximum Softness & Ductility | High-Speed Throughput |

| Ideal For | Deep Drawing, Complex Stamping | High-Volume Production |

Need to Optimize Your Metal's Formability?

Batch annealing is the key to achieving the superior ductility required for demanding applications like deep-drawn automotive parts and appliance housings. At KINTEK, we specialize in providing the advanced thermal processing solutions your laboratory needs to develop and test materials with precision.

Our range of lab furnaces and consumables are designed to replicate and optimize industrial processes like batch annealing, ensuring your R&D delivers reliable, high-performance results.

Let's discuss how we can support your material science goals. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing