Hot pressing of steel, more commonly known in industry as hot stamping or press hardening, is a manufacturing process where a sheet of specialized steel is heated until it becomes pliable, formed into a complex shape, and then rapidly cooled within the press die itself. This integrated forming and quenching process transforms the steel, resulting in a final component that is both exceptionally strong and lightweight.

The core principle of hot pressing is not just to shape the metal, but to fundamentally change its internal structure during the process. It combines the high formability of hot metal with an in-die heat treatment (quenching) to create ultra-high-strength steel parts that would be impossible to form using traditional cold stamping methods.

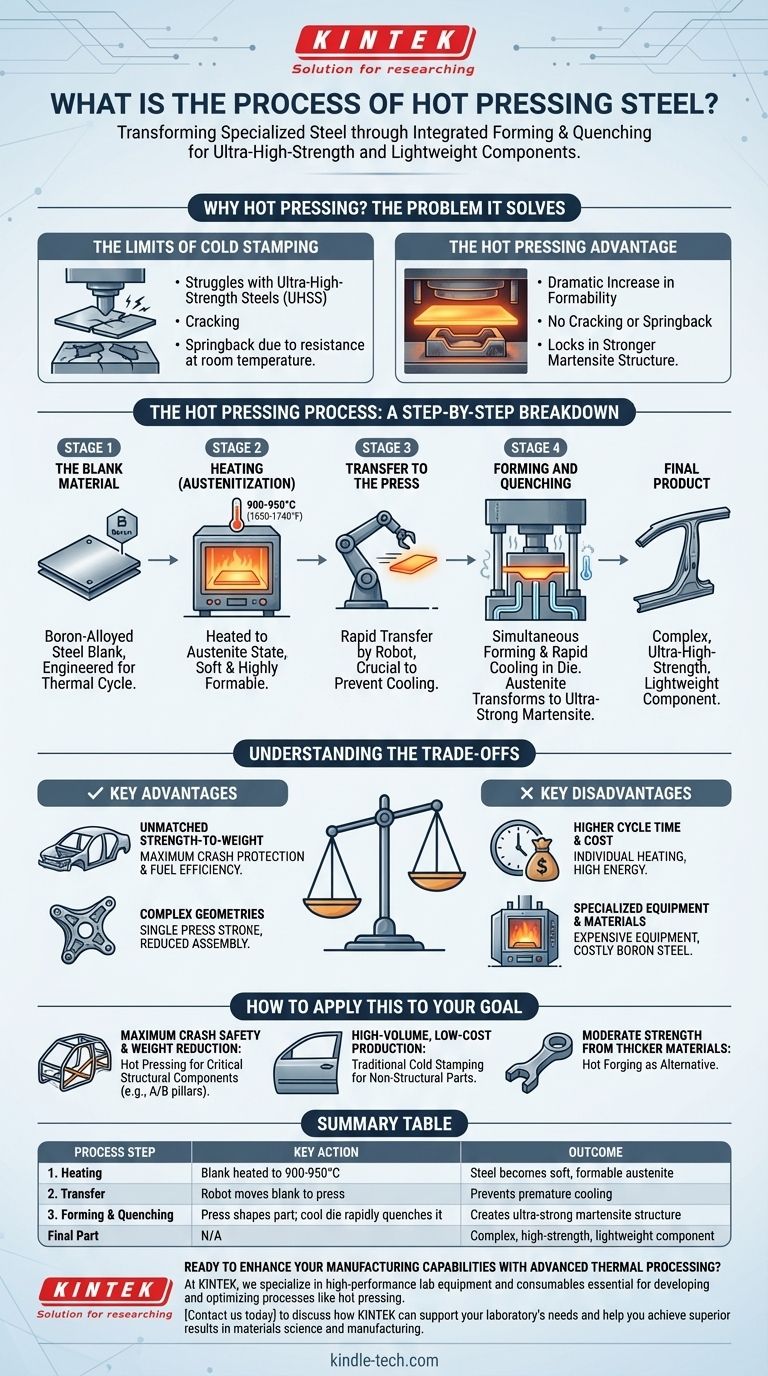

Why Hot Pressing? The Problem It Solves

Modern engineering, particularly in the automotive industry, demands components that are simultaneously stronger for safety and lighter for fuel efficiency. Traditional cold stamping of steel struggles to meet these conflicting goals.

The Limits of Cold Stamping

Cold stamping involves pressing room-temperature steel into a die. While fast and cost-effective, it has significant limitations when working with ultra-high-strength steels (UHSS). These materials are so strong at room temperature that they resist being formed, leading to cracking or "springback," where the part partially returns to its original shape after pressing.

The Hot Pressing Advantage

Hot pressing circumvents these issues entirely. By heating the steel until it's red-hot, its formability increases dramatically, allowing it to be shaped into complex geometries with ease. The subsequent rapid cooling locks in a new, much stronger internal structure, achieving the desired strength without the risk of cracking or springback.

The Hot Pressing Process: A Step-by-Step Breakdown

The process is a precisely controlled sequence of thermal and mechanical stages. Each step is critical to achieving the final properties of the component.

Step 1: The Blank Material

The process begins with a blank, which is a flat sheet of steel cut to a specific shape. This is not ordinary steel; it's typically a boron-alloyed steel, which is specifically engineered to respond perfectly to the heating and quenching cycle.

Step 2: Heating (Austenitization)

The steel blank is moved into a high-temperature furnace and heated to approximately 900-950°C (1650-1740°F). At this temperature, the steel's internal crystal structure changes into a state called austenite. In this state, the steel is soft, highly formable, and ready for pressing.

Step 3: Transfer to the Press

Once the blank is fully austenitized, it must be transferred from the furnace to the press very quickly, often by a robot. This speed is crucial to prevent the blank from cooling down too much before it can be formed.

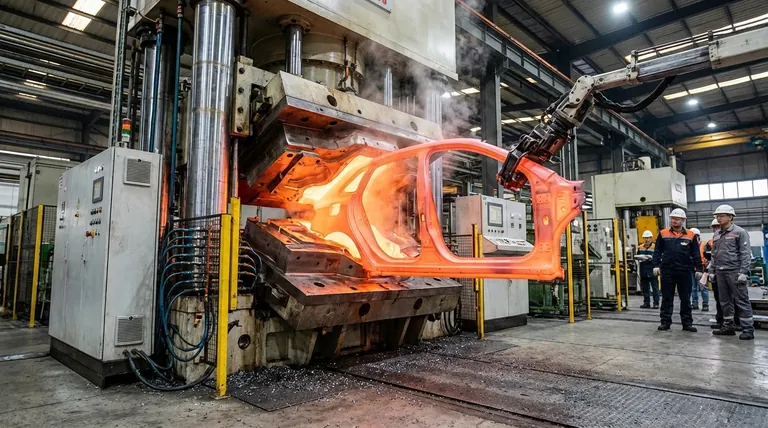

Step 4: Forming and Quenching

This is the defining stage of the process. The hot, pliable blank is placed into a die that has internal cooling channels. As the press closes, two things happen simultaneously:

- Forming: The press exerts immense pressure, shaping the soft blank into the final, precise geometry of the part.

- Quenching: The cool die rapidly extracts heat from the hot part at a controlled rate. This rapid cooling transforms the austenite structure into martensite, an extremely hard and strong crystal structure.

The part emerges from the press already formed and hardened, possessing its final ultra-high-strength properties.

Understanding the Trade-offs

While powerful, hot pressing is not the solution for every application. It involves a clear set of benefits and drawbacks that must be weighed.

Key Advantage: Unmatched Strength-to-Weight

Hot-pressed parts offer an exceptional strength-to-weight ratio. This allows engineers to design components like vehicle safety cages that provide maximum crash protection while minimizing overall vehicle weight.

Key Advantage: Complex Geometries

Because the steel is formed while hot and soft, designers can create intricate and complex parts in a single press stroke. This consolidation of parts reduces assembly complexity and cost down the line.

Disadvantage: Higher Cycle Time and Cost

The need to heat each blank individually makes the cycle time for hot pressing significantly longer than for cold stamping. This, combined with the high energy consumption of the furnaces, leads to a higher cost per part.

Disadvantage: Specialized Equipment and Materials

The process requires expensive, specialized equipment, including high-temperature furnaces and robust, internally-cooled press dies. The boron steel used is also more costly than conventional deep-drawing steels.

How to Apply This to Your Goal

Choosing the right manufacturing process depends entirely on the specific requirements of the component.

- If your primary focus is maximum crash safety and weight reduction: Hot pressing is the definitive choice for critical structural components like A/B pillars, roof rails, and bumper beams.

- If your primary focus is high-volume, low-cost production of non-structural parts: Traditional cold stamping is far more economical for components like door panels or fenders where ultra-high strength is not required.

- If your primary focus is creating parts with moderate strength from thicker materials: Hot forging, a different process involving shaping bulk metal rather than sheet, may be a more suitable alternative.

Ultimately, hot pressing is a sophisticated solution engineered to overcome the physical limits of traditional metal forming for the most demanding applications.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| 1. Heating | Blank heated to 900-950°C | Steel becomes soft, formable austenite |

| 2. Transfer | Robot moves blank to press | Prevents premature cooling |

| 3. Forming & Quenching | Press shapes part; cool die rapidly quenches it | Creates ultra-strong martensite structure |

| Final Part | N/A | Complex, high-strength, lightweight component |

Ready to enhance your manufacturing capabilities with advanced thermal processing?

At KINTEK, we specialize in the high-performance lab equipment and consumables essential for developing and optimizing processes like hot pressing. Whether you are researching new steel alloys or scaling up production, our reliable furnaces, temperature control systems, and durable consumables are designed to meet the rigorous demands of your laboratory.

Contact us today to discuss how KINTEK can support your laboratory's needs and help you achieve superior results in materials science and manufacturing.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the process of pressure sintering? Achieve Superior Density and Strength for High-Performance Parts

- What is electric current sintering? Achieve Rapid, High-Performance Material Densification

- What is the significance of axial pressure in SPS? Achieve 98.8%+ Density in High-Entropy Alloys

- What is the core function of a Vacuum Hot Pressing (VHP) furnace? Achieve 99.7% Density in Ruthenium Targets

- How does the programmable temperature control of a vacuum hot press furnace benefit the reactive synthesis of TiAl?

- Is diffusion bonding the same as sintering? Key Differences in Solid-State Processes

- What conditions does a vacuum hot pressing furnace provide for MgAl2O4? Master Optical Purity in Transparent Ceramics

- What are the advantages of an SPS? Achieve Superior Materials with Unprecedented Speed and Control