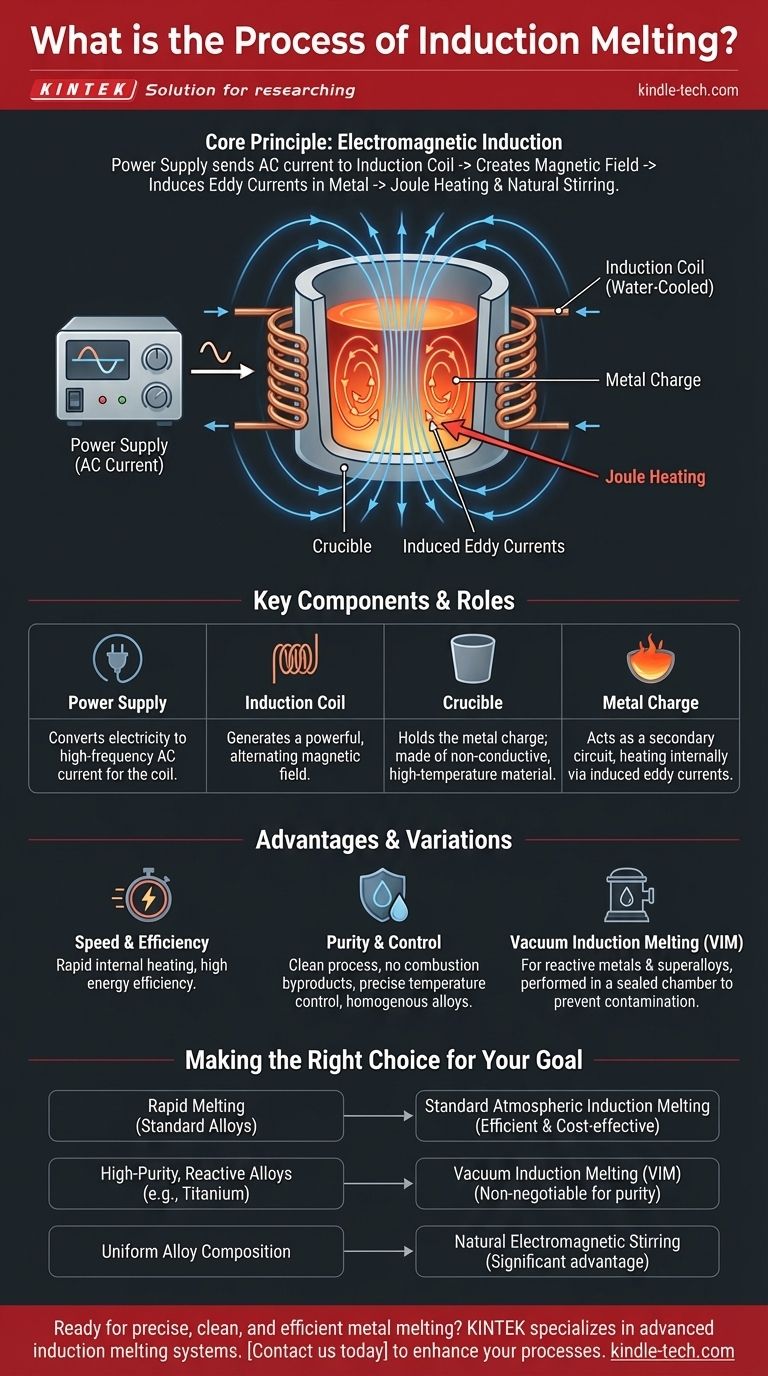

At its core, induction melting is a metallurgical process that uses the principles of electromagnetic induction to heat and melt metal without any direct contact from a heat source. An alternating current (AC) is passed through a copper coil, generating a powerful magnetic field that induces electrical currents within the metal itself, causing it to rapidly heat up and liquefy from the inside out.

The central mechanism of induction melting is electro-thermal conversion. It transforms electrical energy into a magnetic field, which in turn induces internal electrical currents (eddy currents) in the metal, generating intense heat through the metal's own electrical resistance.

The Core Principle: Electromagnetic Induction at Work

Induction melting operates on the same fundamental principles as an electrical transformer. The system is designed to turn the piece of metal you want to melt into an active part of the electrical circuit.

The Power Source and the Coil

The process begins with a high-frequency power supply that sends a powerful AC current through a multi-turn coil, which is typically made of water-cooled copper tubing. This induction coil acts as the primary winding of a transformer.

Creating the Magnetic Field

As the AC current flows through the coil, it generates a strong, rapidly reversing magnetic field in the space within and around the coil. The metal to be melted, known as the charge, is placed inside a crucible positioned within this coil.

Inducing Eddy Currents in the Metal

This powerful magnetic field penetrates the metal charge. According to Faraday's Law of Induction, the changing magnetic field induces circulating electrical currents within the conductive metal. These are known as eddy currents. The metal charge effectively becomes a short-circuited secondary winding of the transformer.

Generating Heat Through Joule Heating

The induced eddy currents flow against the inherent electrical resistance of the metal. This resistance to the current flow generates immense heat, a phenomenon known as Joule heating. Because this heat is generated within the metal itself, the process is incredibly fast and efficient.

The Natural Stirring Effect

A key benefit of this process is the electromagnetic force created by the eddy currents. This force causes a vigorous stirring action within the molten metal bath, promoting chemical homogeneity and uniform temperature throughout the melt.

Understanding the Key Components

A typical induction furnace is a clean and relatively simple system, consisting of three primary components that work in concert.

The Power Supply

A modern solid-state power supply converts mains electricity into the high-amperage, medium-to-high-frequency AC current required for the process. The frequency is a critical variable that can be adjusted based on the type of metal and the size of the melt.

The Induction Coil

This is the engineered copper coil that generates the magnetic field. It is almost always hollow to allow for continuous water cooling, which prevents the coil itself from melting due to the immense radiant heat from the molten charge.

The Crucible

The crucible is the refractory container that holds the metal charge. It must be made from a material, such as ceramic or graphite, that can withstand extreme temperatures and is non-conductive, so it does not heat up from the magnetic field.

Advantages and Process Variations

While highly efficient, the choice of induction melting and its specific configuration depends on the desired outcome, particularly regarding metal purity.

Advantage: Speed and Efficiency

Heat is generated directly inside the material, leading to very rapid melting cycles and high energy efficiency compared to methods that rely on external combustion or heating elements.

Advantage: Purity and Control

With no combustion byproducts, induction melting is an exceptionally clean process. This precise control over temperature and the inherent stirring action makes it ideal for producing high-quality, homogenous alloys.

Process Variation: Vacuum Induction Melting (VIM)

For highly reactive metals and superalloys that readily oxidize or react with nitrogen in the air, the entire process can be performed in an airtight, vacuum-sealed chamber. This process, known as Vacuum Induction Melting (VIM), prevents contamination and is essential for producing the ultra-high-purity materials used in aerospace and medical applications.

Making the Right Choice for Your Goal

Selecting the correct induction process is critical for achieving your specific metallurgical objective.

- If your primary focus is rapid melting of standard ferrous and non-ferrous metals: Standard atmospheric induction melting is the most efficient and cost-effective choice.

- If your primary focus is creating high-purity, reactive alloys (like titanium or nickel-based superalloys): Vacuum Induction Melting (VIM) is non-negotiable to prevent atmospheric contamination.

- If your primary focus is achieving a highly uniform alloy composition: The natural electromagnetic stirring action of any induction melting process provides a significant advantage over static furnace methods.

By understanding these core principles, you can leverage induction melting to achieve precise, clean, and efficient control over your metallurgical process.

Summary Table:

| Component | Role in the Process |

|---|---|

| Power Supply | Converts electricity to high-frequency AC current for the coil. |

| Induction Coil | Generates a powerful, alternating magnetic field. |

| Crucible | Holds the metal charge; made of non-conductive, high-temperature material. |

| Metal Charge | Acts as a secondary circuit, heating internally via induced eddy currents. |

Ready to achieve precise, clean, and efficient metal melting?

KINTEK specializes in advanced lab equipment, including induction melting systems designed for superior performance. Whether you are working with standard alloys or high-purity reactive metals, our solutions offer the speed, control, and purity your laboratory demands.

Contact us today to discuss how our induction melting technology can enhance your metallurgical processes and meet your specific research or production goals.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting