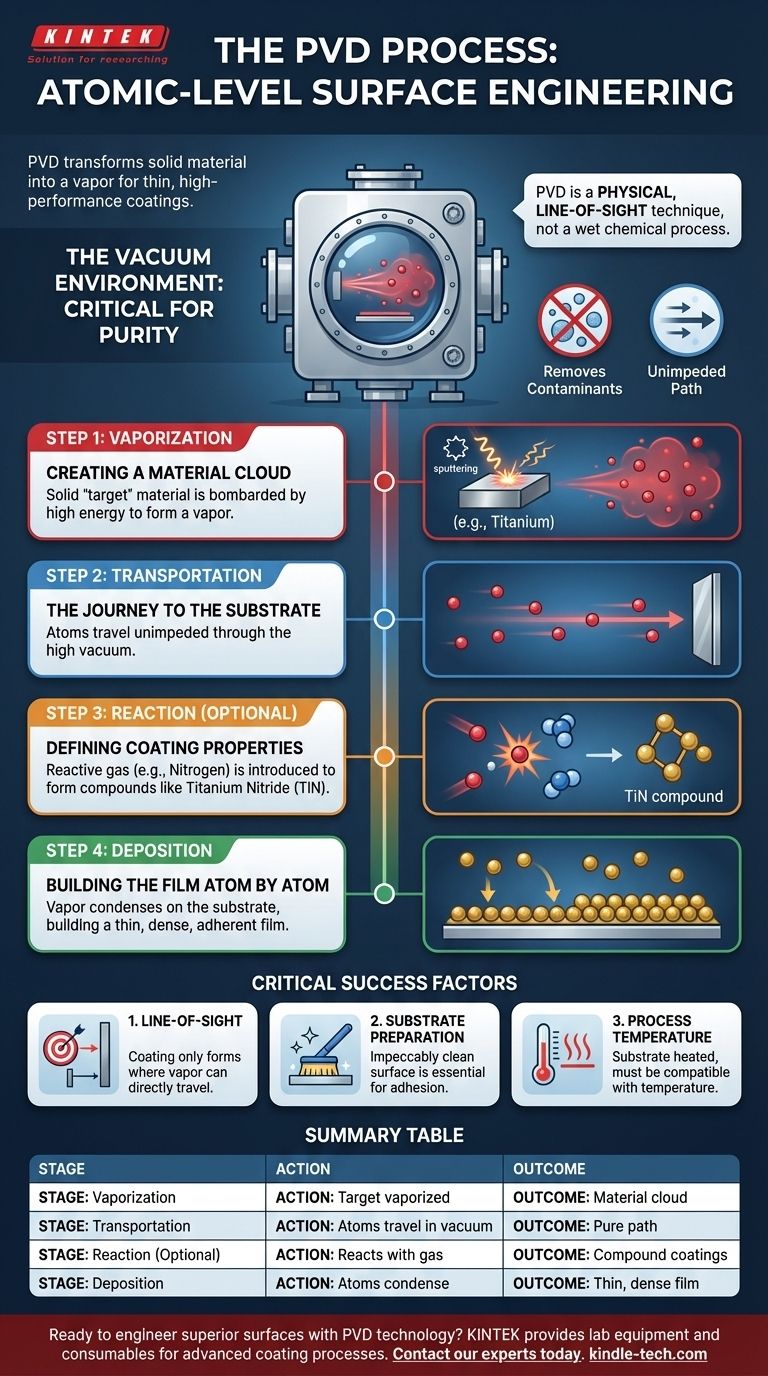

At its core, the Physical Vapor Deposition (PVD) process is a vacuum-based technique that transforms a solid material into a vapor, transports it atom by atom through the vacuum, and then deposits it as a thin, high-performance coating onto a substrate. This method is fundamentally about building a new surface layer from the ground up, providing precise control over the final properties of the finish.

The essential insight is that PVD is not a wet chemical process like plating; it is a physical, line-of-sight technique conducted in a high vacuum. This vacuum environment is the key that allows individual atoms of a coating material to travel unimpeded from a source to the target part, ensuring a pure, dense, and strongly bonded film.

The Environment: The Critical Role of the Vacuum

Before any coating can occur, the proper environment must be established. The entire PVD process takes place inside a sealed vacuum chamber.

Why a Vacuum is Non-Negotiable

The high vacuum (very low pressure) is critical for two reasons. First, it removes air and other gas molecules that could contaminate the coating or react with the vaporized material in an uncontrolled way.

Second, it provides a clear, unobstructed path for the coating atoms to travel from their source to the part being coated, which is known as the substrate.

Deconstructing the PVD Process: Step-by-Step

While specific techniques vary, every PVD process follows three fundamental stages. A fourth, optional reaction stage is often included to create specific high-performance ceramic coatings.

Step 1: Vaporization - Creating a Material Cloud

The process begins with a solid source material, known as the target. This target is made of the material we want to use for the coating (e.g., titanium, chromium, aluminum).

A high-energy source is used to bombard this target, dislodging atoms and converting them into a vapor or plasma. Common methods include sputtering, which uses ions to knock atoms off the target, or thermal evaporation, which uses heat to boil them off.

Step 2: Transportation - The Journey to the Substrate

Once vaporized, these atoms or molecules travel through the vacuum chamber from the target towards the substrate. The vacuum ensures they travel in a straight line without colliding with other particles, which would disrupt the process.

Step 3: The Reaction - Defining the Coating's Properties

This is an often-critical stage where the final properties of the coating are defined. For many applications, a specific reactive gas (like nitrogen, oxygen, or methane) is precisely introduced into the chamber.

The vaporized metal atoms react with this gas to form a new compound. For example, titanium vapor will react with nitrogen gas to form the extremely hard, gold-colored compound Titanium Nitride (TiN). If no reactive gas is used, the original source material deposits in its pure form.

Step 4: Deposition - Building the Film Atom by Atom

When the coating vapor reaches the substrate, it condenses on the cooler surface. This condensation builds up, atom by atom, to form a thin, dense, and highly-adherent film.

Because the film is built at an atomic level, it conforms precisely to the surface texture of the substrate while providing a completely new set of surface properties.

Common Pitfalls and Considerations

PVD is a powerful technology, but its effectiveness depends on understanding its operational principles and limitations.

Line-of-Sight Dependency

PVD is a "line-of-sight" process. The coating can only form on surfaces that the vaporized source material can directly travel to. This makes it challenging to evenly coat the inside of complex shapes or deep, narrow holes.

Substrate Preparation is Everything

The adhesion and quality of the PVD coating are critically dependent on the cleanliness of the substrate. The surface must be impeccably clean—free of oils, oxides, and any other contaminants—for the atomic bond to form correctly. Improper cleaning is a primary cause of coating failure.

Process Temperature

While PVD is considered a "low temperature" process compared to techniques like CVD, the substrate is still heated to several hundred degrees Celsius. This temperature must be compatible with the substrate material to avoid warping or altering its fundamental properties.

Making the Right Choice for Your Goal

Understanding the stages of the PVD process allows you to specify the right type of coating for your application.

- If your primary focus is extreme hardness and wear resistance: You need a reactive PVD process that creates a ceramic coating, such as Titanium Nitride (TiN), Chromium Nitride (CrN), or Titanium Carbonitride (TiCN).

- If your primary focus is a specific decorative color or conductivity: A non-reactive PVD process depositing a pure metal (like titanium or aluminum) or a specific alloy is likely the optimal choice.

- If your component has complex internal geometries: You must account for PVD's line-of-sight nature and ensure the part is fixtured correctly, or consider if an alternative, non-line-of-sight process is more suitable.

By controlling each step of this atomic-level construction, PVD allows for the precise engineering of surfaces with superior performance.

Summary Table:

| PVD Process Stage | Key Action | Outcome |

|---|---|---|

| 1. Vaporization | Target material is vaporized (e.g., via sputtering). | Creates a cloud of coating atoms. |

| 2. Transportation | Atoms travel unimpeded through a high vacuum. | Ensures a pure, direct path to the substrate. |

| 3. Reaction (Optional) | Vapor reacts with a gas (e.g., Nitrogen). | Forms compound coatings like Titanium Nitride (TiN). |

| 4. Deposition | Atoms condense and bond to the substrate. | Builds a thin, dense, and highly adherent film. |

Ready to engineer superior surfaces with PVD technology? KINTEK specializes in providing the lab equipment and consumables necessary for advanced coating processes. Whether you're developing wear-resistant tools or decorative finishes, our solutions support precise, high-quality results. Contact our experts today to discuss how we can meet your laboratory's specific PVD and surface engineering needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells